The north-central and western regions of the U.S. are important sugar beet-producing regions. Minnesota, Idaho, North Dakota, Nebraska, Montana, California, Wyoming, Colorado and Oregon were all among the top 10 states nationally in sugar beet production in 2011.

Processing plants in these regions refine the sugar from the beets and produce large volumes of byproducts, which are useful feed ingredients for beef cattle producers.

Many producers are seeking alternative feeds to incorporate in their beef cattle diets and still meet animals’ protein and energy requirements.

Producers have a variety of options to choose from in alternative feeds; however, the choice of those feeds depends on several factors, including availability and nutrient composition as well as storage and handling characteristics.

One possibility is to incorporate sugar beet byproducts into the diet.

Sugar beet processing

At the processing plant, foreign material, small beets and leaves are removed from the beets prior to processing.

This material is known as “sugar beet tailings,” which also is used as livestock feed.

The sugar beets are sliced into long strips called cossettes.

The cossettes are cooked in hot water to remove the sugar. This process is called diffusion.

At the end of the diffusion process, the hot water and sugar mixture is further processed into bulk or bagged sugar.

The cossettes are conveyed to a pulp press, which squeezes some of the water from the pulp to facilitate transportation.

Pulp that will be marketed as dry shreds or pellets is conveyed to a pulp dryer. The pulp dryer dries the pulp to approximately 10 percent moisture.

After drying, the pulp is pelleted to facilitate storage and transportation.

Molasses is produced during the refining process. The volume of molasses produced varies but is typically about 4 to 5 percent of the weight of the raw sugar beets.

Molasses is separated from the juice (which contains the sugar) through a series of centrifugation steps. Molasses contains 40 to 50 percent residual sugar.

Sugar beets

Occasionally, processors must dispose of whole sugar beets due to spoilage or excessively large crops. Whole beets can be fed successfully to cattle.

Whole beets are low in crude protein (6.8 percent) but high in energy (75 percent to 81 percent total digestible nutrients, or TDN).

If possible, whole beets should be broken up prior to feeding. Producers can utilize extended mixing times with a conventional mixer wagon to break up whole beets.

In addition, some producers report success using manure spreaders to spread whole beets on stubble or stalk fields and allowing cows access to the beets on the field.

Choking may be a potential problem when feeding whole beets.

Whole sugar beets also can be fed by chopping in a tub grinder or forage harvester to reduce the risk of choking.

Some producers have noted success by using a forage harvester to chop the beets prior to feeding.

Whole sugar beets can be chopped and ensiled as a storage method.

As with any ensiling process, good silage-making principles should be employed. These principles should include achieving the proper moisture level (typically 60 to 65 percent moisture is required).

Beet pulp

Beet pulp can be used effectively as a supplement for gestating or lactating cows, as an ingredient in backgrounding diets or as a replacement for roughage in finishing diets.

Beet pulp is relatively low in crude protein (8 percent) but relatively high in TDN (72 percent).

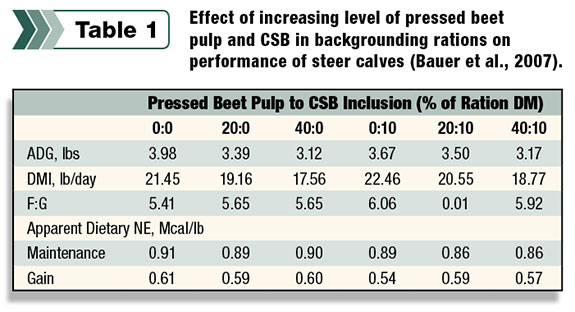

Research conducted at NDSU indicates that wet beet pulp can be included at up to 40 percent of the diet (dry matter, or DM, basis) in backgrounding diets (see Table 1).

However, reductions in DM intake will occur at inclusions greater than 20 percent of the diet.

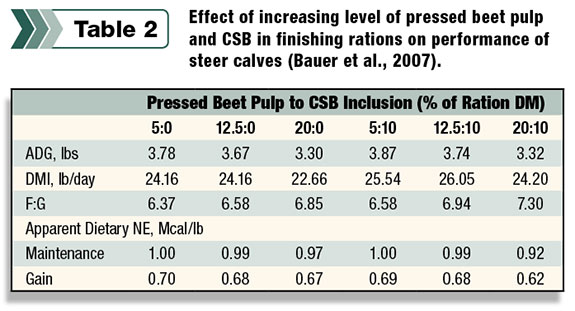

In finishing diets, wet beet pulp can be used as the roughage source, having an energy value greater than corn silage (see Table 2).

As a partial or complete roughage replacement, it can be included at 5 to 15 percent of the diet in finishing rations (DM basis).

Data collected at NDSU indicates pressed beet pulp has 94 percent the energy value of corn in backgrounding diets and 86 percent the value of corn in finishing diets (Tables 1 and 2).

When wet beet pulp is fed at 20 percent of the diet DM, cattle will consume 30 to 35 pounds of wet pulp, which would be less than 1 percent of their bodyweight on a DM basis.

As with any feedstuff, diets should be balanced to meet the protein and energy needs of the class of cattle being fed.

There is no limitation on the amount of beet pulp that could be included in a beef cow ration from a nutritional standpoint.

However, in most practical applications, no more than 50 percent of the ration (DM basis) as beet pulp would be fed due to the reductions in intake that may occur at high levels, as well as moisture content and bulkiness of the diet.

Beet pulp is available as either a wet (pressed shreds) or dry byproduct (shreds or pellets). Because beet pulp contains large amounts of digestible fiber, it usually does not create a problem with acidosis for cattle consuming beet pulp. The distance that wet beet pulp can be transported is limited by the moisture content.

Dry pelleted pulp should be stored in bins or commodity sheds to protect it from moisture and rodents. Wet pulp can be stored effectively in silage bags or in trench or bunker silos.

Beet tops

Advancements in defoliator technology have limited the usefulness of beet tops, since the beet tops essentially are mulched as they are removed.

This causes difficulties in gathering the remaining residue into a windrow or for cattle to graze the material.

Beet tailings

Beet tailings consist of small beets, broken or damaged beets, soil and other foreign material not suitable for sugar production.

Tailings are high in moisture (75 to 85 percent) and can be quite variable in nutrient content.

With low levels of soil contamination and foreign material, beet tailings have a feeding value similar to or slightly greater than corn silage on a DM basis.

However, high levels of soil or foreign material will reduce the energy content of tailings substantially. Choking may be a problem with beet tailings. Due to the high moisture content, transportation is a major expense with beet tailings.

Molasses

Beet molasses is used primarily as a source of energy (75 percent TDN) in animal feed, but it also is included in rations to improve palatability and to reduce dust.

It also is added to manufactured feeds as a binder for pellets and a carrier for urea or other nonprotein-nitrogen sources, vitamins and minerals.

Fifteen percent of the diet is the maximum recommended level. Beet molasses contains relatively high levels of potassium, sulfur, magnesium, sodium and chloride, compared with cereal grains.

Beet molasses must be stored in a well-insulated, heated tank. At temperatures above 110 degrees, it can be pumped easily with a 2.5-horsepower to 3-horsepower pump and 3-inch tubing.

Obtaining sugar beet byproducts

Sugar beets typically are processed from early fall (September) through late spring (May).

Availability of sugar beet pulp and other byproducts declines through the summer months as companies sell inventory that accumulated during the processing season.

In this region, Midwest Agri Commodities is the main supplier of sugar beet byproducts.

Producers should work with commodity brokers to establish contracts and ensure they have access to adequate amounts of byproducts for the winter feeding season. ![]()

Greg Lardy is a beef cattle extension specialist at North Dakota State University; Rebecca Schafer is a livestock extension educator at South Dakota State University.

PHOTOS

TOP: A South Dakota rancher feeds his cattle a mixture of hay and sugar beet byproduct. Photo courtesy Andrew Mach/News21.

BOTTOM: Whole beets can be fed successfully to cattle, but many producers prefer pulp and other byproducts, including molasses. Photo courtesy of Progressive Cattleman staff.