Now may be a good time to look at your mineral program. In late gestation, the cow will be setting the calf up to meet its future trace mineral needs by filling the fetal liver with relatively high concentrations of trace minerals.

Cows top off their calf’s liver stores during this time because milk is a poor source of trace minerals. Thus, once born, the calf is dependent on its stores until it starts eating significant quantities of solid feeds. Typically, cows pull from their own liver stores during late gestation to meet the demands of the calf.

Thus, it is important to ensure the cow has adequate stores to pull from. In cow-calf systems, the calf is most likely to be negatively affected by trace mineral deficiencies.

So how do you make sure you are meeting your herd’s needs? This is not an easy question to answer and likely the reason why so few guidelines are available. On the surface, planning a mineral supplementation program seems simple. Evaluate the mineral requirements of the animal and compare it to the intake of mineral. Then, supplement what does not meet the requirement. Unfortunately, minerals interact with each other and other components of the diet, making mineral nutrition complex and precision supplementation virtually impossible. Especially when you add in the complication of using free-choice minerals and the varied intake that naturally comes with this form of supplementation.

Although there is much variability in the mineral content of forages, there are some generalizations that can be made. The two most common deficiencies nationwide are copper (Cu) and zinc (Zn). On average, 25% of the cow’s requirement for zinc is supplied by forage (when assuming 50% bioavailability).

Only about 25% of the cow’s copper requirement is supplied by the forage, again assuming 50% bioavailability from the forage. Additionally, elevated concentrations of copper antagonists (iron, molybdenum and sulfur) are often encountered. The targeted intake of copper should be above the requirement when these antagonists are present in the diet. Sulfur content above 0.25% will cause decreased availability of copper, especially if coupled with as little as 1 part per million (ppm) of molybdenum. Thus, due to antagonists, the amount of copper in supplements often needs to provide 100% to 150% of their requirement.

Another trace mineral that should be considered is selenium (Se). The amount of selenium in forages is quite variable; generally it is recommended to provide supplemental selenium (unless selenium toxicity has been observed in the area) when cattle are consuming stored or brown forages. These forages will have lower vitamin E content, and the functions of selenium and vitamin E are interrelated. However, it is important to note that the difference between selenium adequate and selenium toxic levels is extremely narrow. Thus, if feeding multiple fortified supplements or using injectable minerals that supply selenium, it is important to pay attention to how much supplemental selenium is being provided to avoid toxicity.

Manganese (Mn) is often sufficient in pastures but may need to be supplemented when grazing or feeding mature forages, as concentrations can be low or corn silage where high iron can reduce absorption of manganese. In fact, in the past few years, I have heard of several cases of manganese deficiency due to feeding corn silage-based diets without supplemental manganese.

Testing your forage is a good first step in developing your mineral program. The key when sampling forages is to minimize dirt contamination, sample the forages that are being selected for by the cattle at the time of sampling and to sample at multiple times of the year to align forage mineral content with the appropriate supplement formulation.

Given the year-to-year variation in forage mineral, it’s a good idea to do this over multiple years to get reasonable estimates of typical mineral content. Although this will require initial investments in labor and analysis, it can save money in the long run.

A good mineral program does not have to be expensive, nor is cost correlated with effectiveness. It pays to shop around when it comes to mineral; this is because a significant amount of the cost can be in the packaging and handling. I have seen a lot of operations cut their mineral programs in half by working with local mills and getting a custom mineral mix made. Some mills will mix as little as a ton at a time, while others may require a 4-ton minimum. So again, shopping around is key to finding what can work for you.

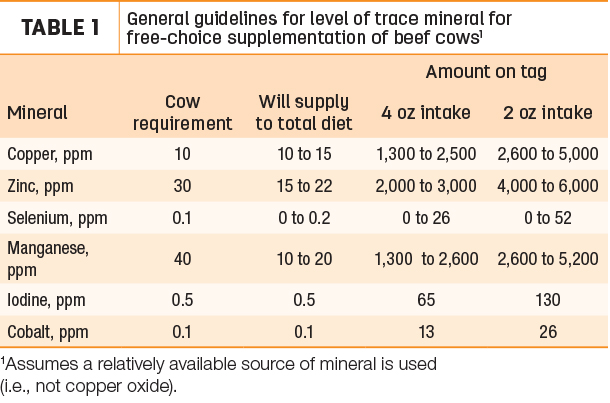

Based on the typical concentrations of minerals in forages, the following guidelines are a starting point when developing or selecting a free-choice mineral supplement. The general guidelines can help one visualize the relationship between the amount of mineral being provided in the diet (when feeding a 2- or 4-ounce intake free-choice mineral) with various concentrations of minerals.

Seek local advice. These guidelines are not one-size-fits-all. Testing your forage and water sources can always help you see where you stand. Someone from your local extension office can help provide guidance as to common issues and needs for the area as well as help with interpreting your test results to develop a program that will work best for you.