Over the years, cattlemen have proven resourceful in finding nutrient sources for feeding cattle. Recent challenges caused by drought, supply chain issues and conventional feed ingredient availability have only emphasized the need to recognize and potentially utilize alternative ingredient sources.

There are a huge number of ingredients, byproducts or co-products that can be used as cattle feed. Many of these are commonly used in both commercial and on-farm feed manufacturing. We are generally well acquainted with standard feed ingredients such as corn, grain sorghum, oats, barley, wheat, cottonseed meal, soybean meal, canola meal, etc. These are all basic ingredients and are used in virtually any species, particularly corn and soybean meal. It’s generally the value and availability of these primary ingredients that almost everything else is valued by and compared to. Interestingly, cottonseed, soybean and canola meal are technically all co-products of oil production but are still considered primary ingredients.

The next group, all co-products, are also very common in cattle feeds. Ingredients like dried distillers grains (DDGs), corn gluten feed, soybean hulls, cottonseed hulls, whole cottonseed, wheat midds and rice bran are regularly used in commercial feed manufacturing as well as on-farm/ranch feed manufacturing programs.

Then we get into more unique feed ingredients such as wet ingredients like brewers grains, distillers grains, potato waste, vegetable or produce waste. Less common dry ingredients may include beet or citrus pulp, cotton gin trash, almond hulls, cookie meal and candy waste. Additional options include damaged ingredients. It is not uncommon to find smoke-damaged ingredients (i.e., whole cottonseed) from when a storage building catches fire. While you won’t find these every day, some brokers will specialize in damaged ingredients.

The focus of this article will be on the last group: less common ingredients that can be used effectively in a nutrition program but may require some special considerations for handling and use.

Alternative feed sources

As discussed earlier, circumstances over the last couple of years have created challenges in the acquisition and cost of many commonly used feed ingredients. Additionally, keep in mind that some feed ingredients – corn for instance – are also used for a variety of applications (ethanol, sweeteners, whiskey, oil). Additionally, other species such as chickens and swine are big competitors for corn and soybean meal used as animal feed sources. When these are in short supply, their cost goes up and producers begin looking more to other ingredients to meet their feeding requirements.

Cattle producers have a unique opportunity given that cattle, as ruminants, can use a long list of alternate feed ingredients that are not used for other (more industrial) purposes as well as consumed by other species. It’s not unreasonable to make the observations that you can feed a cow almost anything if it can be broken down in the rumen and if you adapt them to it properly.

Let’s look at some of these more unique feed ingredients.

Wet or high-moisture feeds

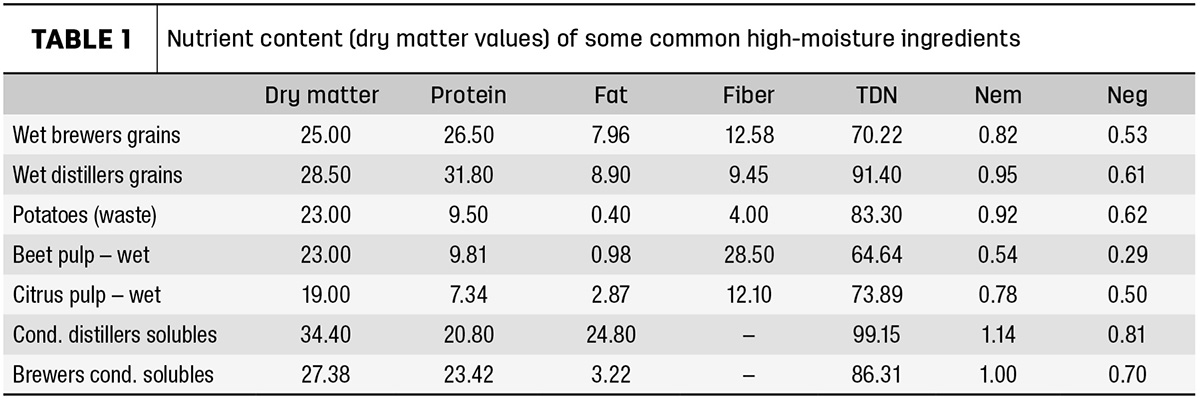

Table 1 lists some of the more common high-moisture ingredients that can be sourced and fed. The big consideration is that these must be sourced closely to the point of production. (It’s expensive to haul water.) These also have a short shelf life, perhaps a week or less. They are also often only available in truckload quantities.

These are just a very few of the many high-moisture feed ingredients available for use in cattle-feeding programs. As you can see, most of these are very good protein and/or energy sources. Additionally, most of these are very palatable and will work well in a feed mix. In some cases, it has not been unusual to see producers feed these and other high-moisture ingredients alone and not mixed with other ingredients. This may not be a good idea, since some of these can have some challenges and could create digestive issues. For instance, while not shown on the table, potato waste is very high in starch, which can result in bloat or acidosis when fed at high levels. Most of these ingredients are better used in a balanced mix.

Dry feeds

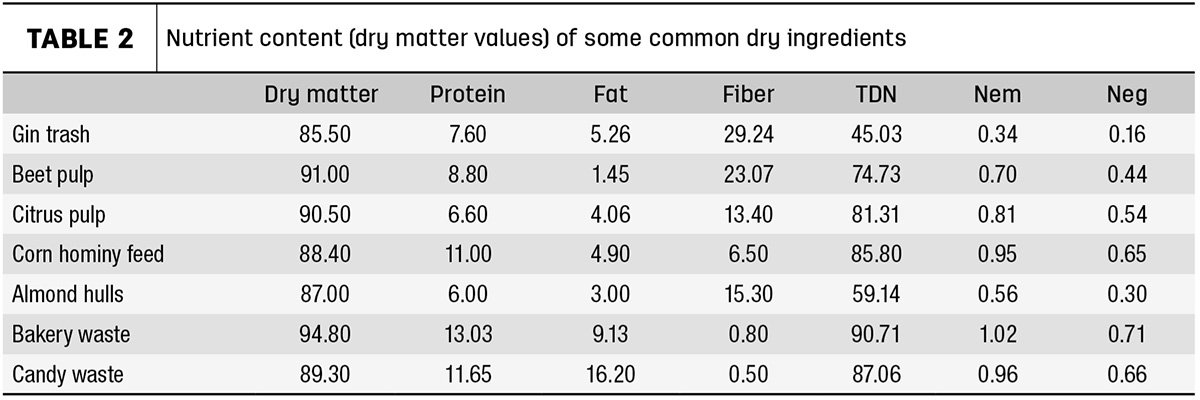

Table 2 provides some nutrient details for some of the more common dry ingredients that can also be fed to cattle as sources of protein and energy.

This is a very small sample of various dry ingredients that can be found and used in cattle feeds and can be used to replace the nutrients normally sourced from more conventional ingredients.

Considerations and limitations

As mentioned, these and a multitude of other ingredients can be effectively used in a well-designed feeding program. They can be used to maintain or enhance performance as well as used cost-effectively. You may also find some of these available from local feed mixing companies that have a source of more unique ingredients and have learned how to incorporate them into quality formulations. For the producer who wants to consider these or any number of other more unique ingredients, there are some considerations and limitations to evaluate.

- Since there are commonly some concerns with nutrient levels or actual feeding, it is helpful to work with a nutritionist who may have familiarity with feeding a particular ingredient or groups of ingredients in a cow, transition calf or growing heifer or bull program. An experienced nutritionist can help design and balance the program effectively.

- Often, these ingredients are only available in truckload quantities (45,000 pounds or more) and in bulk. Thus, their use requires the ability to store and handle these ingredients effectively. It also requires the ability to effectively mix these ingredients with others.

- High-moisture ingredients may require a “pit” or similar structure to hold the material in place. Actual liquids will require a tank, pump, etc.

- High-moisture ingredients also have a limited shelf life, maybe a week to 10 days at the most. Therefore, it is necessary to be able to feed an entire load (or a given quantity the supplier will sell) within a specific period to prevent spoilage. It may be possible to extend the shelf life by applying a product like propionic acid to reduce the pH and reduce the level of mold growth. It is imperative to wear proper protective gear (goggles, face shield, gloves) when applying a preservative of this nature.

- Locating supplies of this nature generally requires some work. There are some brokers who specialize in the procurement and sale of these alternative ingredients. In other cases, it may be necessary to go directly to the manufacturing source (ethanol production facility, brewery, distillery, cotton gin, etc.). However, in many situations, these companies may have some third party that manages the sale of their co-products.

- Use of such ingredients often requires a substantial investment for storage, handling and feeding. This may include a commodity storage building, tractors with front-end loaders, mixer wagon (preferably with scales), feed troughs or bunks.

Conclusions

There are many alternative feed ingredients that can be used in a well-designed feeding program. Use of many of these ingredients requires commitment and should be carefully evaluated before taking these steps. While the money saved in feed may be substantial, the cost of the necessary ability to handle, store and feed may offset potential savings. It is critical to research and evaluate extensively.