It’s accepted knowledge the major players in the North American beef industry include cow-calf operations, feedlots and packing plants. But it takes more to power an entire industry, and without the massive contributions of a strong supporting cast filling the varied gaps, it would quickly crumble.

Here are a few unsung influences whose contributions help build long-term success for beef producers.

Designing for success

It might be said corral designs set the stage for either good or poor cattle-handling practices.

Growing up in the Nebraska Sandhills, Jake Schubert learned the physical aspects of building ranch equipment in his father’s shop. From there, he transitioned into computer design of fencing and corral layouts for feedlots, ranches and sale barns all across the U.S. His national success quickly expanded worldwide, kickstarting his own business of Aurochs Consulting and leading him to design opportunities in Europe and Asia.

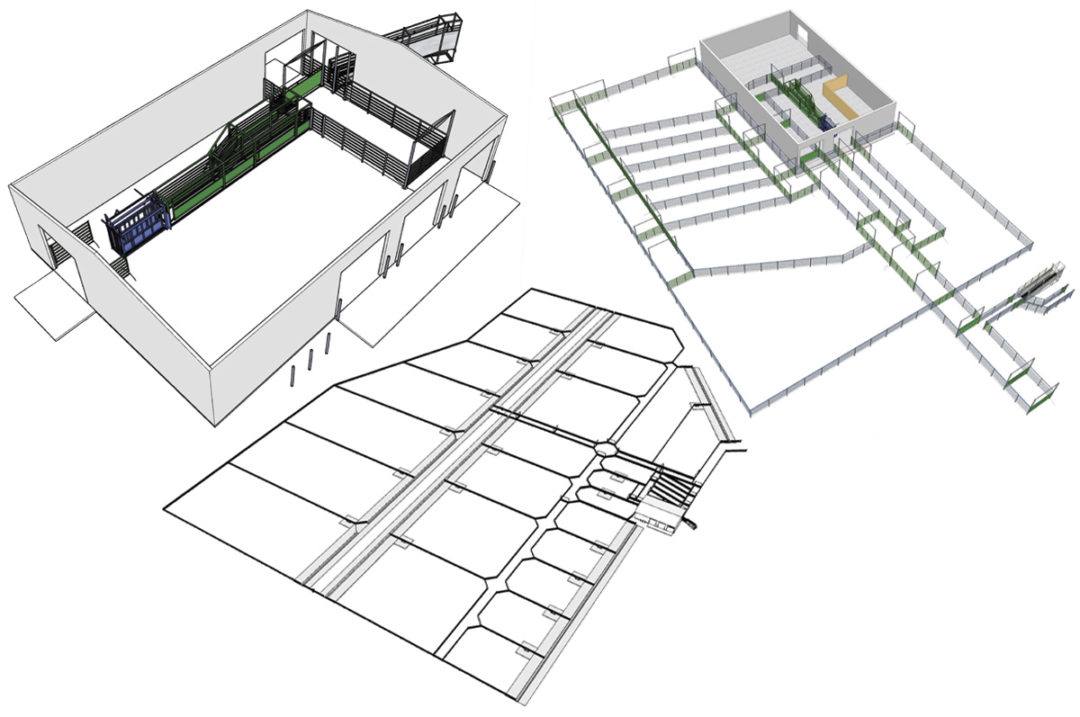

Schubert begins with hand-drawn sketches, followed by those created from the computer program SketchUp.

“A typical project is designing a homestead or set of corrals for a young rancher who wants to get it right from a handling and workflow perspective,” Schubert says. “After a few video calls and some back-and-forth to get everything operating perfectly, I create a 3D project model. Once we’re happy with it, I'll make 2D drawings with a bill of materials to build from.”

Schubert sees cattle-handling facility design processes changing in the future, with more prefabricated corrals allowing on-site work to be minimized, an increased attention to planning due to rising costs of materials and labor, and improved automation as tools become cheaper and simpler to use.

“Most of the advancement will be in designing,” he says. “Physical corral fence and gates won’t change much, but how they’re arranged and how people are trained to use them will.”

Schubert explains that as technology evolves, more owners will have access to 3D model viewing through shared links and QR codes. Low-cost 3D scanning tools are already beginning to provide accurate scans of existing buildings. Augmented and virtual reality tech is also improving in application. He believes designing adds value to the beef industry by delivering maximum versatility in handling systems, ensuring they function as the client needs without wasting time, labor and materials.

“Producers see their corrals before they cut a single piece of pipe, meaning we test a design for workability and address problems before anything is built,” Schubert says. “We get it right, making things calmer and safer for both handlers and animals.”

Looking beneath for herd improvement

Carcass marbling, the most significant factor in beef flavor and tenderness, largely determines USDA grading and meat quality, ultimately impacting profitability.

Recognizing the degree of marbling before animals are harvested is where ultrasound expert Donnie Robertson of Robertson Livestock takes the lead. Robertson uses high-frequency sound waves to measure and interpret carcass traits in finishing yards, in seedstock operations to gather data for establishing accurate expected progeny differences (EPDs), for cattle targeting niche or value-added markets, and on ranches selecting replacement heifers.

Ultrasound software developed by John Brethour at Kansas State University allows producers to plug in data such as premiums and discounts, average cost of gain and weight to receive graphs of sorting parameters and estimates of when an animal will reach the highest grade for optimal profit.

“Professor Brethour used to say, ‘We scan for profit,’” says Robertson. “Ultrasound adds value in so many ways. It can remove outliers who won’t make the grid, establish EPD data for heritability and lineage, or put together a group of heifers that, when mated to the right bulls, will grade well and produce high-quality calves.”

He believes that even with the higher percentages of cattle currently hitting top carcass grades, using chuteside ultrasound is still beneficial, especially when backgrounds aren’t known.

“It’s a little more labor-intensive, but if we can make more money on our calves or increase the value and quality of our herd, it’s wise to consider doing it,” Robertson says. “From my standpoint, it’s worthwhile, especially with niche markets, value-added and branded beef opportunities.”

Insure for safety, savings and productivity

“The very nature of the agricultural business is inherently dangerous,” says Ken Worsley, chief operating officer (COO) of Nova Mutual Insurance, Jarvis, Ontario. “Farm buildings are generally remote and unprotected frame constructions, without hydrants or nearby firefighting assistance, so it’s critical we stop fire threats well before they become big problems.”

Worsley considers farm insurance companies more than industry fringe players because where there are mortgages, there must be insurance.

Nova Mutual, like many other North American agricultural insurers, puts a large focus on fire prevention and safety. Rather than simply covering building, feed or machinery losses, they actively assist with prevention strategies. Full-time loss prevention staff visit farms and ranches at no cost, completing on-site surveys and inspections, searching for risks and perils owners either may not be aware of or have been putting off.

“We come up with a list of recommendations to repair over the next few months, some more urgent than others,” Worsley says. “We try to reduce exposure to all different kinds of loss.”

Nova Mutual also uses thermographic imaging technology to pinpoint electrical hot spots in receptacles and breaker boxes. Newer farm equipment also presents fire hazards, as they feature stricter environmental controls, which cause them to run hotter. Twenty-four/seven, 365-days-a-year electrical monitoring systems are also available to alert owners of small problems before they become large catastrophes.

“It’s beneficial for all parties if we keep our rates stable,” Worsley emphasizes. “Farmers keep their equipment working properly and reduce their losses. We understand they’re busy, so we do our best to help them with necessary prevention and repairs before a barn burns down and they suffer a massive loss. And honestly, it helps us as a company too, so everyone comes out a winner.”

While cow-calf operations, feedlots and packing plants grab the most press and media coverage, the North American beef industry performs well largely because of consistent value-based contributions from those in unheralded sectors.