How are these inedible, black spots getting into the beef supply? That’s everyone’s first question after learning about birdshot as the leading contributor to foreign objects in packing plants and further processing facilities. As one of the foremost experts on this subject recently stated, people are either shocked and appalled, or they hang their heads in embarrassment or shame, quickly understanding the source of the issue.

Birdshot or shotgun shell pellets have been found and reported in the beef supply since the first National Beef Quality Audit in the early ’90s, but the presence of this foreign material in the food we produce is not subsiding. In fact, the opposite may be true, or it may be that we are detecting it better in the industry.

One of the most respected experts in the country on ground beef processing recently updated a packed, standing-room-only crowd on the significance of this plague of foreign objects on the beef industry. For context, this ground beef processor makes 5 million ground beef patties each day. Most of us in the room that day knew birdshot was an issue, but what we learned next got the room of 300 cattle enthusiasts both fired up and sick to their stomachs at the same time.

With those 5 million patties a day in mind, a defect rate of 1% is unacceptable. That would be 50,000 patties of wasted beef. A defect rate of 0.1% is 5,000 patties. A single incidence of birdshot found in the processing lines costs $10,000 in lost product and downtime. Why so much? If a pellet made it through the grinder, one pellet may have been sheared into numerous pieces that are barely detectable. Also, anyone who has ever fired a shotgun knows that where there is one, there are potentially dozens more, but let’s not get ahead of ourselves here. Back to the speaker.

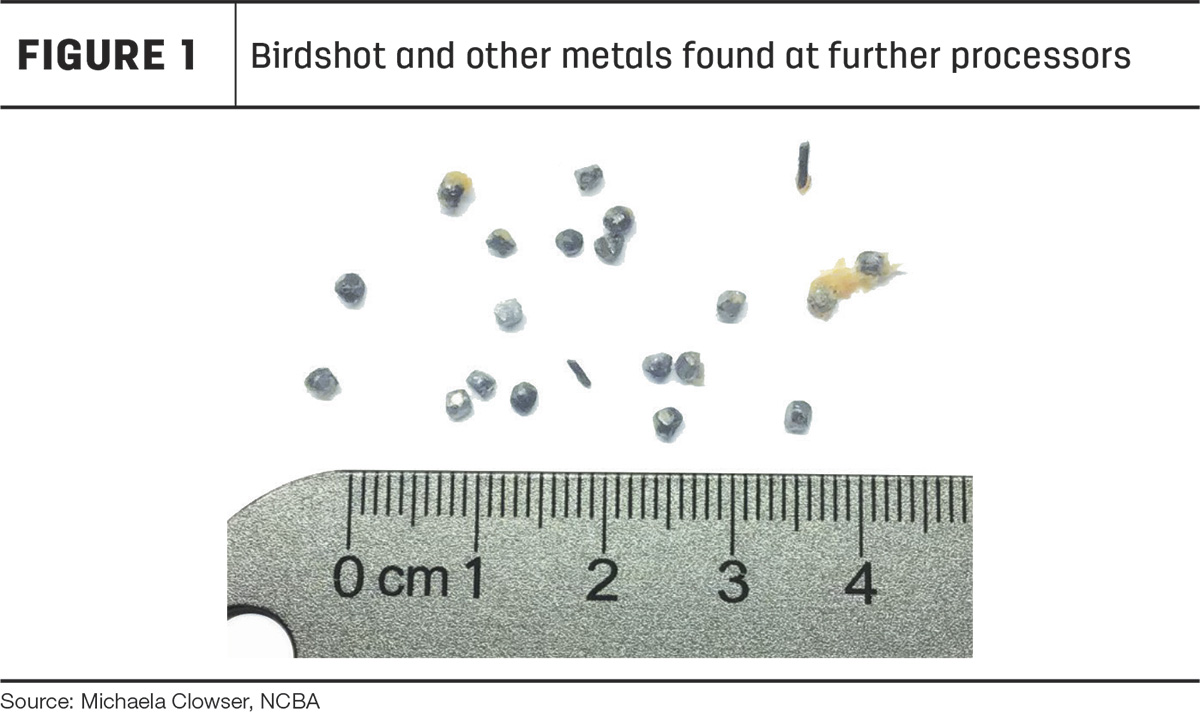

He went on to present the stats on foreign objects in their plant. He showed pictures of various items that unintentionally show up from packing plants. The items mostly consist of large and easily identifiable objects. They don’t want those either, but they know who to contact in many of those cases. In fact, there are roughly about 28 categories of items that they document each year as foreign material. Most of those items are found around one to 15 times each on an annual basis.

Birdshot, however, is found around 105 times a year and well over two times the rate of any other foreign object. Please understand that this is just data from this one further processor. There are dozens more processors with the same statistics.

“Can’t you just get some metal detectors to fix this?” is often our first thought. Well, the further processor referenced in this article shared that they have spent $2 million on a dozen metal detectors and a number of X-ray machines. Each metal detector must be checked for functionality every 15 minutes.

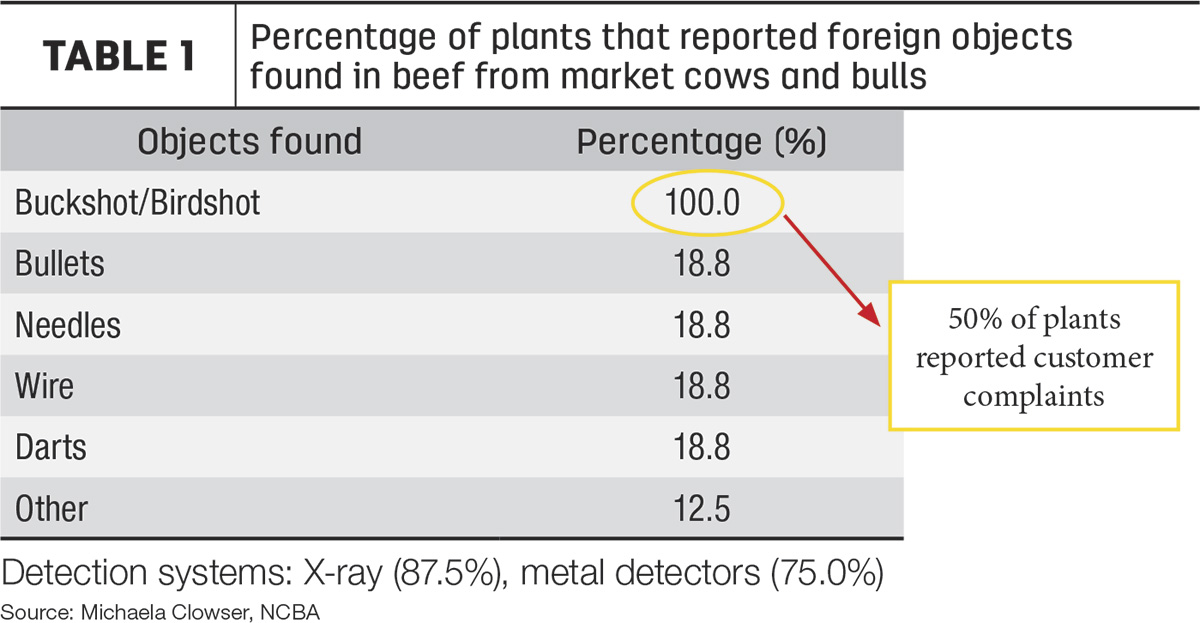

Every further processor surveyed in the National Beef Quality Audit reported birdshot as a problem. Of that 100% of further processors reporting birdshot, 50% report consumer complaints (Table 1).

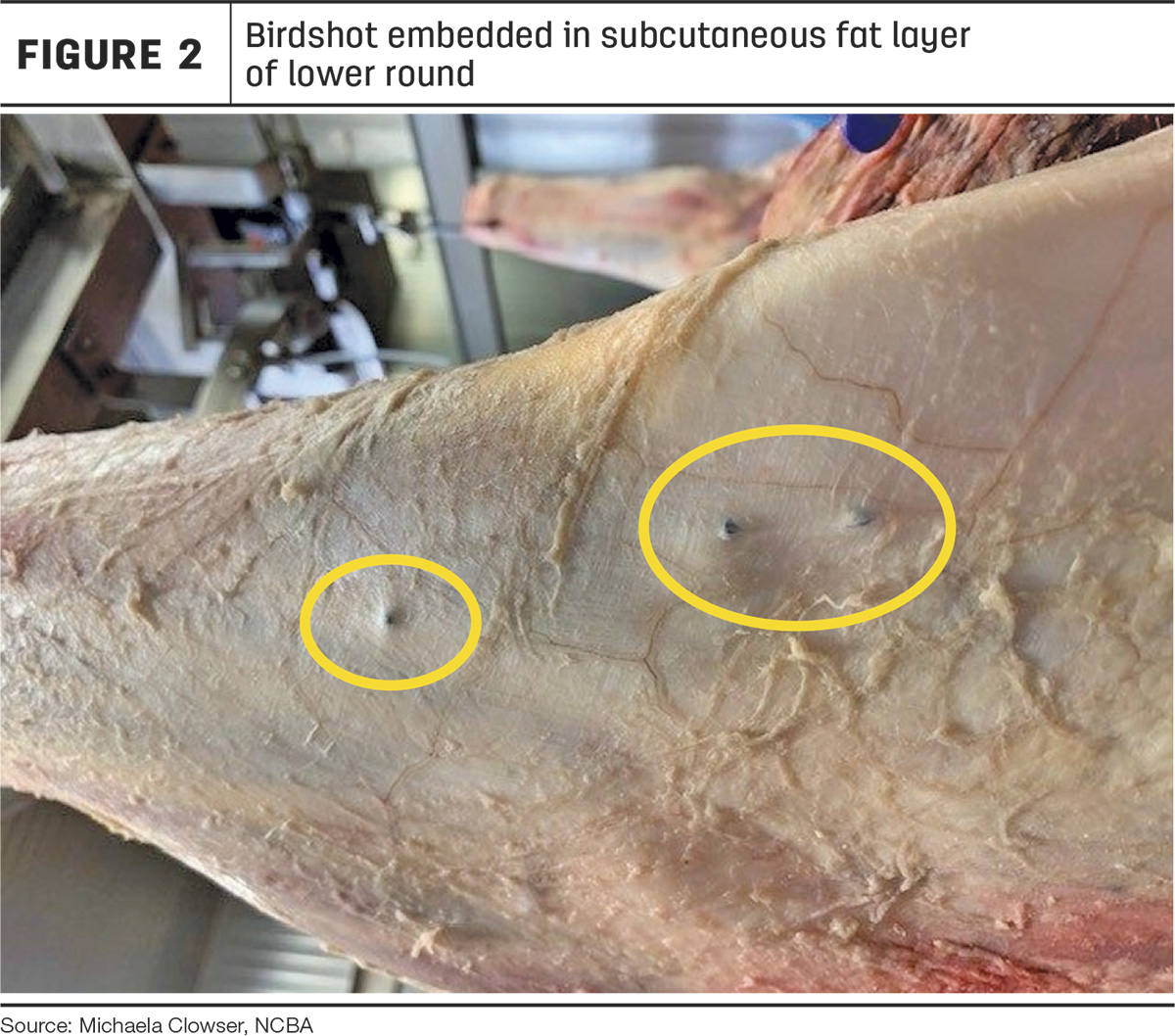

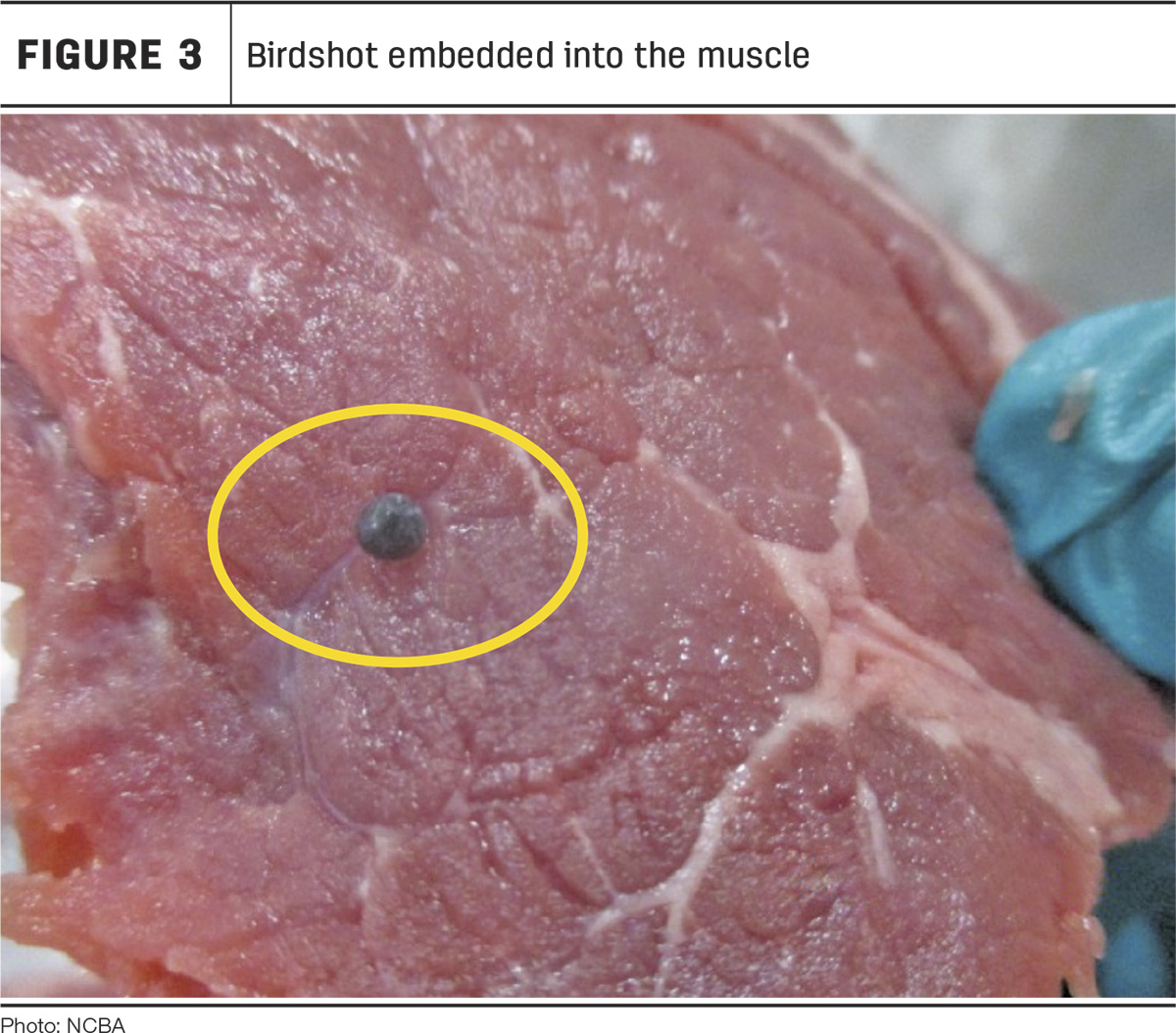

“You must be exaggerating,” and “This cant’ be true,” are common replies. The ground beef processing and beef industry at large has documented numerous pictures and cases (Figures 1, 2, 3).

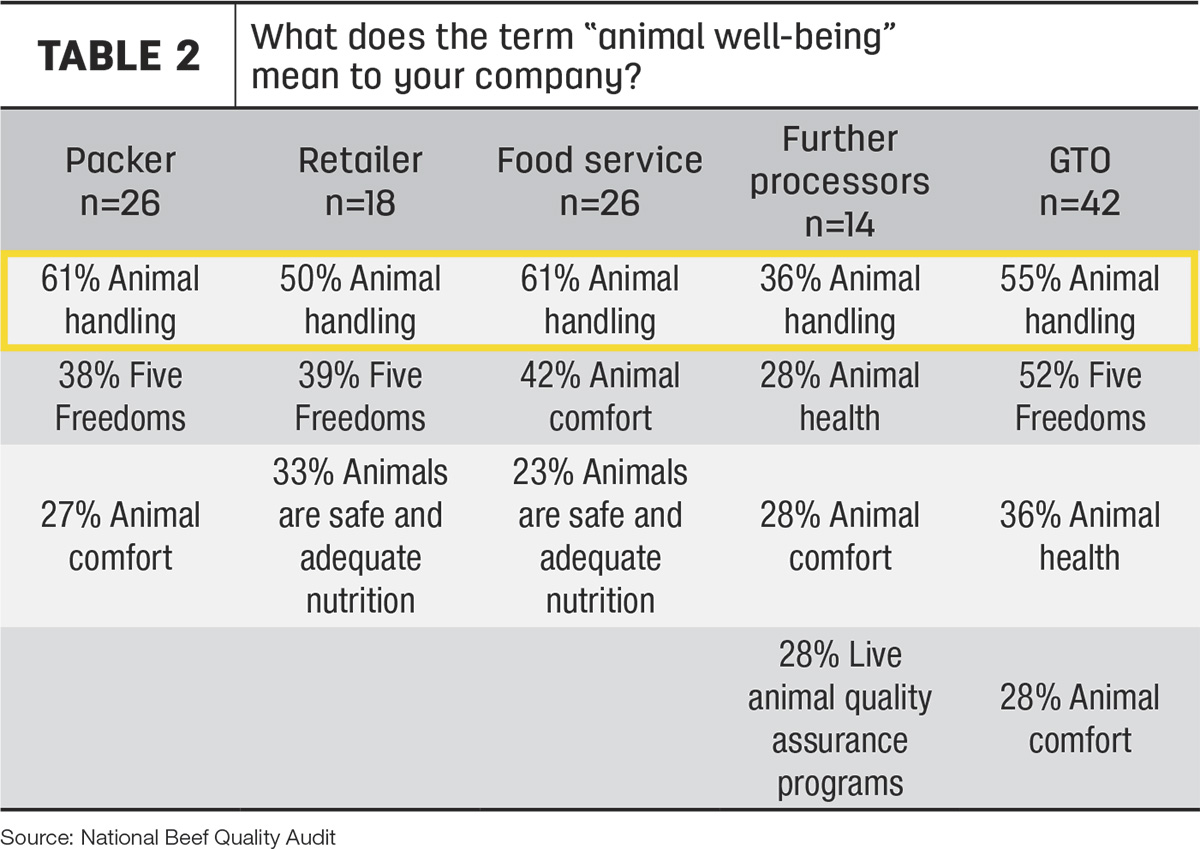

The National Cattlemen's Beef Association’s National Beef Quality Audit has the data and interviews to further solidify the issue in an objective manner. The National Beef Quality Audit asked packers, further processors and others in the industry what “animal well-being” meant to their company. “Animal handling” was their top response (Table 2).

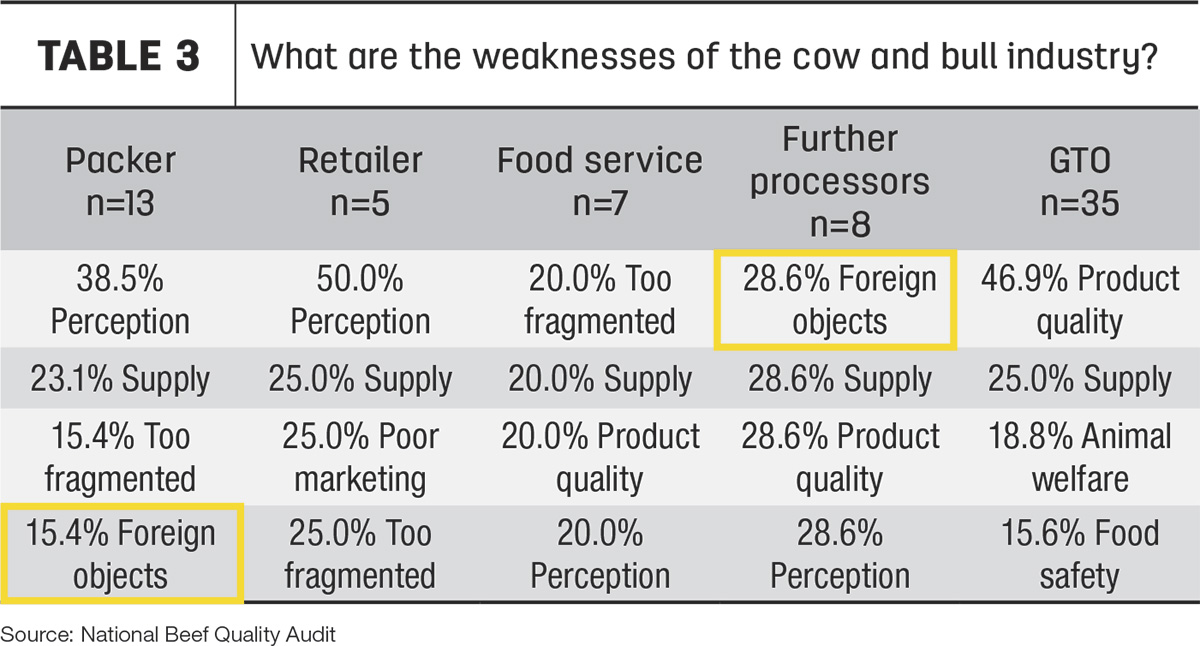

How does that tie into the discussion? Well, packers, and particularly further processors, both mentioned foreign objects as one of the most significant weaknesses in the cow and bull side of the industry (Table 3). To cut right to it, there are some out there handling their cattle with shotguns. Not only is it poor animal handling, it’s inhumane and flat-out ridiculous. If you’re curious, yes, I am holding back my words here, but I am fired up about this topic. Neither birdshot nor buckshot will bounce off cattle and somehow go away. Bulls, no matter how stupid, should not be shot. Cows, no matter how deep in the brush or how big a ranch they are on, should not be shot at whether intentionally or by accident.

Just to clarify, no, hunters are not to blame. The big picture is that it must stop. We need everyone on board to get the message out in our chapter and state meetings, educational programming and just word of mouth. This is not something we should share in social media. However, there are social media cowboys sharing videos of themselves gathering cows and bulls not knowing the difference between quail and cows who are trying to garner a TikTok fan base. If we all focus on promoting the “right way” mentality of Beef Quality Assurance, we can make a difference. It may even prevent a trip to the dentist for some child and eliminate another black spot in the industry that’s impossible to chew.