Preparing for corn silage harvest with a game plan can pay dividends to your feeding program in the immediate future. As the plant matures and harvest approaches, begin walking the fields and tracking conditions so timely harvest plans can be made.

Harvesting before corn reaches optimal moisture can result in:

- Decreased yield per acre

- Decreased starch deposition

- Poor silage fermentation

On the other hand, delaying harvest can result in:

- Reduced fiber digestibility

- Reduced starch digestibility

- Poor packing density, increasing the incidence of mold and spoilage

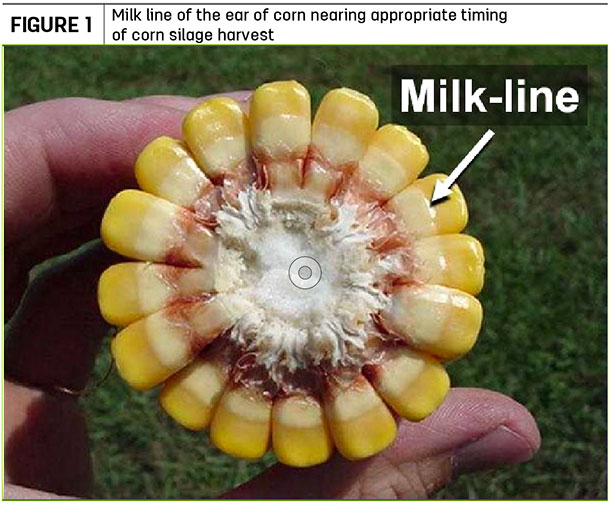

A quick moisture estimate can be done by breaking a cob in half and looking at the kernels within. The milk line – an apt name for the white color line on the kernel – will move from the outer edge of the kernel toward the cob.

Harvest should typically begin when the milk line reaches the halfway mark, when half of the kernel is milky and the other half is doughy, as shown in Figure 1.

It is important to note that the milk line should only provide a rough estimate point and should not be relied upon solely to determine moisture content. Whole plant moisture will typically change by 0.5 units per day and can change up to 1 unit in dry conditions, so plants must be monitored closely as they begin to reach optimal dry matter.

Determining dry matter percentage can be done in several ways. Collect a chopped sample (small residential wood chippers work well to process), and dry it down using either a commercial forage moisture tester, food dehydrator, air fryer or microwave oven.

If using a microwave oven (quickest method) to determine moisture content:

1. Weigh out 100 grams of fresh forage on a plate or container. (Be sure to subtract the weight of the container.)

2. Spread the fresh forage out evenly, and place in the microwave.

3. Heat on high for four minutes.

4. Remove the silage and container from the microwave, and record the weight.

5. Heat the sample in the microwave for one minute.

6. Remove the sample, and record the weight.

7. Repeat steps 5 and 6 until the weight stabilizes.

8. Once the weight stabilizes, record the weight and subtract the remaining weight from 100. For example, if the weight stabilized at 35 grams, the dry matter would be 35% and the moisture would be 65% (100 - 35 = 65).

To get an accurate estimate, be sure the same individual performs the dry matter procedure, and never leave the microwave unattended as the corn silage can ignite if left in the microwave for too long.

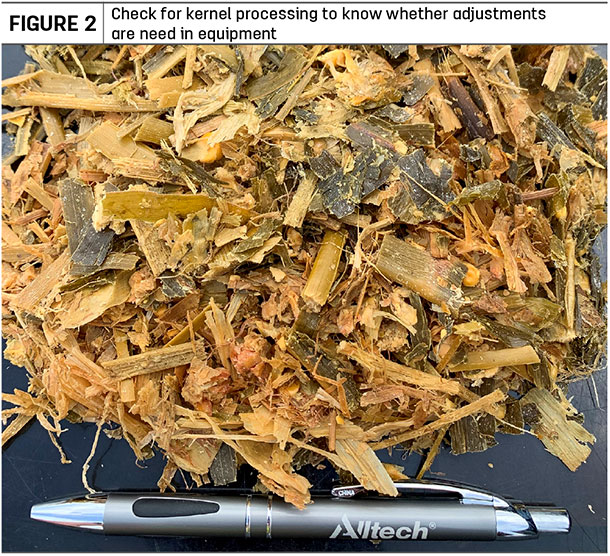

How to evaluate kernel processing on farm:

1. Fill a 5-gallon pail roughly halfway with water, and place two to three handfuls of processed corn silage in the water.

2. Gently agitate the silage to help separate the kernels from the stover mat.

3. Skim the floating stover from the water, and remove from the bucket.

4. Carefully drain the water from the pail, and remove the kernels for evaluation.

To be considered properly processed, there should be almost no whole or partially cracked kernels (Figure 2). The presence of several whole kernels indicates that processing is insufficient. If there are cracked or broken kernels, there may be opportunities to improve the processing. ![]()

-

Angie Manthey

- Dairy Nutritionist

- Hubbard Feeds

- Email Angie Manthey

-

Jon Pretz

- Dairy Nutritionist

- Hubbard Feeds

- Email Jon Pretz