By the time you are reading this article, small-grain silage (triticale and rye), along with first-cut alfalfa or haylage will be in the bunk and, for many farms, they may already be in the ration.

As spring progresses to summer, the percentage of haylage and small grains in total mixed ration (TMR) often increases to stretch corn silage inventories, or to dilute corn silage if the quality isn’t as good as we had hoped.

A successful harvest and excellent forage quality are not the results of a single discussion or a few good days in the field. It is a year-long, continuous team effort.

From the previous year’s harvest, feedout, planning future crop needs, nutrient management, inventory management and Mother Nature, the efforts to produce the best quality feed are truly a year-round team effort (Figure 1).

As we move through haylage cuttings, we become more focused on corn silage. Corn silage is the crop; the greatest percentage of the ration. It’s important to take some time to focus on strategies for silage success. While it can be easy to focus on the negatives and things we cannot control (i.e., Mother Nature), it’s important to take a step back and focus on what we can impact. From a management standpoint, are we doing everything in our power to ensure a successful harvest and put up the best quality feed?

The basis of quality silage is proper management from chopping to sealing

Achieving good silage requires good management. Focus on what you can impact or start from the foundation, and work your way up. The first two items on the list have zero to do with the crop. They focus on the people: communication and safety. Once those topics have been covered, we can focus on the silage. Harvest at the optimum dry matter (DM), correct chop length, proper compaction and sufficient sealing.

Maturity

The maturity of the crop reflects the antagonism between quantity (yield) and quality (digestibility). When determining optimal maturity for chopping, you must consider the balance between the total neutral digestible fiber (NDF) and the total starch versus NDF digestibility and starch digestibility. Knowing the needs and goals of your farm allows you to make the best decision for you versus what might be best for your neighbor.

Optimum dry matter

Hitting the target DM is critical for reducing the risk of undesirable fermentation, minimizing effluent, maximizing packing density and excluding oxygen from storage. The target DM for corn silage is 34%, with an ideal range of 32%-36% DM, and a realistic range of 30%-38% DM at harvest. As the DM moves outside of this range (wetter), you are at a greater risk of clostridic fermentation and higher effluents. As DM increases outside this range, there is a greater risk for yeast and molds, longer aerobiosis and more compaction problems. As DM increases, there can also be a negative impact on quality and digestibility. As DM increases from the 35%-40% DM range to the 40%-45% DM range, ruminal starch digestibility and total tract NDF digestibility (TTNDFD) decrease.

Correct chop length and KPS

Don’t rely on the machine settings! Periodically check chop length and kernel processing score (KPS) to ensure target achievement. The target KPS at chopping is more than 70% of the starch passing through a 4.75-millimeter sieve.

Compaction

When making any type of silage, oxygen is the enemy. Packing is required to remove as much oxygen as possible to facilitate and support the anaerobic fermentation process. A key factor to focus on when packing: Match the delivery rate to packing tractor weight – exceed the rule of 800.

Rule of 800: Packing tractor weight = 800 x tons of forage delivered/hour

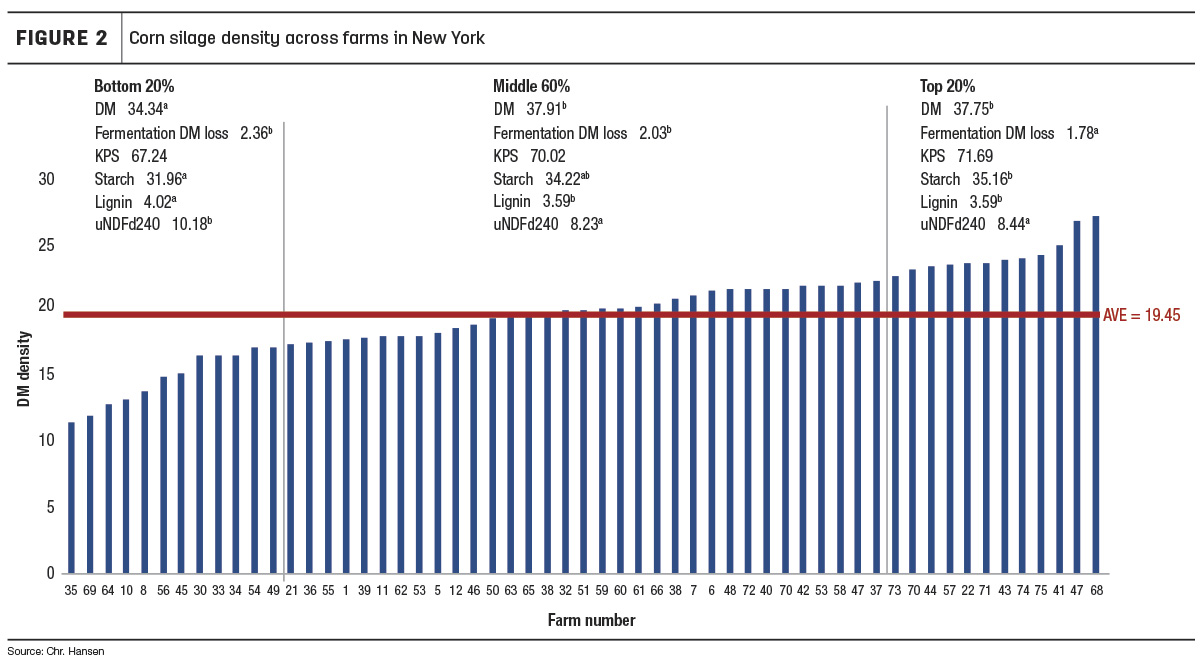

Thin layers spread and packed in a progressive wedge formation will facilitate higher densities for bunkers and piles. Packing is complete when every square foot of the top layer has tire tracks, has been run over twice and is smooth. Focusing on and increasing packing increases your storage space, without impacting the footprint. Well-packed bunks are set up for better fermentation and nutrient preservation and are easier to deface. A DM density goal of greater than 18 pounds of DM per cubic foot is achievable for many farms (Figure 2).

Sealing

Likely the least favorite and dirtiest – yet most valuable – activity on the farm is covering the pile. Once packing is complete, a top-layer inoculant can be applied to increase protection against spoilage. Covering the bunk should occur quickly, safely and efficiently. Using oxygen-barrier plastic, paired with traditional black/white plastic, and properly weighing everything down ensures the silage is sealed and oxygen cannot enter. It also protects the forage from moisture (rain and snow) and other contaminants.

When you are focused on best management practices, the use of a science-based, research-proven inoculant will be the icing on the cake. The proper silage inoculant for your specific needs helps ensure speedy fermentation, DM and nutrient preservation, aerobic stability and reduces top-layer spoilage.

Having a successful silage program is truly a year-round team effort. Lots of planning and decision-making occurs prior to planting and harvesting a high-quality forage. Once harvest is over, the conversations and management don’t stop. The next conversation to have with your team? Feedout management.