Profitable livestock production requires many quality management skills that all impact the technical results. Factors such as health status, barn temperature, ventilation, water quality and nutrition all play a big role in animals reaching their genetic potential and improving the producer’s bottom line.

Exposure to suboptimal water sources

Often, waterlines that are poorly maintained contain biofilm buildup caused by contaminated water sources or sources high in minerals, like iron and manganese. This can offset the water-feed ratio and decrease feed efficiency and therefore milk production. When we consider the fact that it takes four litres of water to produce one litre of milk, the role of quality water is crucial.

As not all animals are healthy, respiratory diseases (and others) will sit and grow in water bowls and troughs; in combination with feed deposits left in water sources, there are many challenges to keeping water clean and fresh. With evolving concerns like the rise of the highly pathogenic avian influenza (HPAI), there is a chance that animals cross-contaminate each other by drinking out of the same water source. Furthermore, most dairy animal housing systems have birds flying in and out, which increases the risk of spreading diseases.

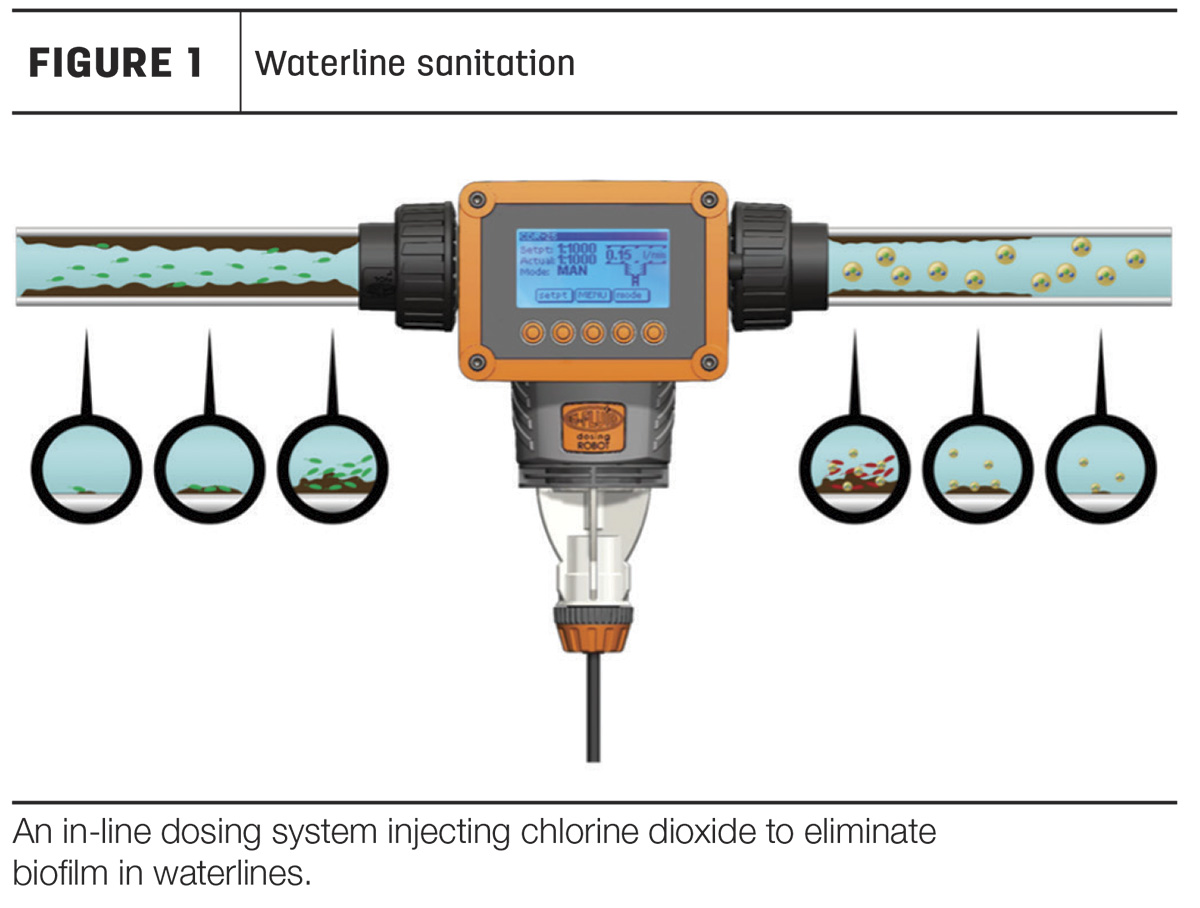

A common practice of tipping water troughs and cleaning them thoroughly twice a week will help keep contamination to a minimum. Chlorine dioxide is an excellent choice to effectively disinfect and secure proper water line sanitation (Figure 1), keeping the communal water sources clean and safe.

Chlorine dioxide oxidizes hydrogen sulphides, which produce bacteria that can cause leaky gut and inflammatory bowel disease. These bacteria and diseases can lead to reduced feed efficiencies, lesions and possible ulcers. There is a range of hydrogen sulphide-producing bacteria commonly found in the gastrointestinal microbiome. Major players of hydrogen sulphide production in the gut are (Figure 2):

- Klebsiella

- Salmonella

- Enterococcus

- Streptococcus

- Campylobacter

- Staphylococcus

- E. coli

Role of chlorine dioxide (ClO2)

Chlorine dioxide is effective within a wide pH range (4 – 10), unlike chlorine which becomes less effective once the pH is greater than 7. Chlorine dioxide is a known disinfectant for bacteria and viruses. Using chlorine dioxide instead of chlorine can assist in reducing the formation of harmful disinfection byproducts, for example, trihalomethanes and halogenated acetic acids. At the right concentrations, chlorine dioxide mixed with water forms a safe stock solution that can be added to the dairy’s drinking water distribution.

The chlorine dioxide molecule in water will oxidize the cell walls of pathogens (by pulling layers off). It can adopt five electrons (5e), which gives chlorine dioxide 2.5 times more capacity to deactivate pathogens at lower dosing rates compared to most other disinfectants, like ozone and hydrogen peroxide which can only adopt two electrons (2e).

Hydrogen peroxide and ozone are short-actives and usually require high dosing rates to maintain a residual at the end of the line. The high dosing level makes them extremely powerful and non-selective oxidizers, therefore capable of killing pathogens and harming healthy (aerobic) cells.

The impact of oxidation on the rumen

Like most mammals, ruminants’ bodies are designed around oxygen, and they require the best oxidation potential to maintain a healthy life. When used in appropriate quantities, chlorine dioxide has a similar oxidation potential to regular oxygen in the body. It is not only important what will be oxidized, but also what will not be oxidized (such as beneficial bacteria in the stomach).

The rumen is anaerobic (meaning there is little to no oxygen present). Microbes present in the rumen cannot grow in the outside air and can only tolerate small amounts of oxygen. The rumen allows for the growth of rumen microbes and the process of fermentation to digest feed and forages for the cow. Any disruption to the delicate balance of the rumen environment will result in poor growth of the microbes, poor health and digestion, and ultimately lower milk production.

Conclusion

Providing high water quality in dairy farming is crucial for optimal milk production, health, and feed efficiency by reducing pathogens, while ensuring correct disinfectant dosages to protect beneficial rumen microbes. Treating water with an appropriate dosage of chlorine dioxide should result in an overall decrease in pathogens and an increased return on investment.