By weight, water is the most important nutrient in a milking cow’s ration, easily making up greater than 80 percent of total intake by weight. We hope you have been motivated to have your farm’s drinking water tested for the things that most often lead to water quality issues:

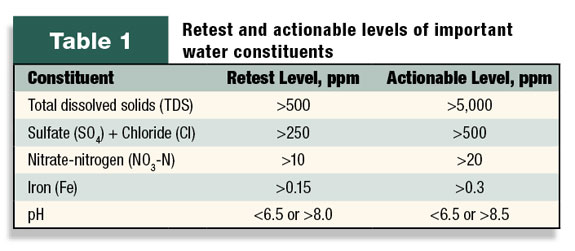

Total dissolved solids (TDS), sulfate (SO4), chloride, (Cl), iron (Fe) and nitrate-nitrogen (NO3-N). Further water testing and/or treatment should be considered if any of those things are greater than certain acceptable levels. (See Table 1.)

At higher levels they may negatively affect animal health and/or milk production, interfere with the germicidal activity of cleansers and sanitizers (e.g., chlorine) and cause problems with water system components (e.g., pipes and pumps).

In fact, some water quality problems like excess iron can lead to such poor animal performance (e.g., health problems, reduced milk production) that it can be a “business-breaker.”

High levels of iron or nitrate-nitrogen also can endanger human health if people are drinking from that water source.

If levels reach “retest levels,” further testing is warranted and one should even consider sending multiple samples to multiple certified laboratories to confirm or deny whether these issues are truly problematic.

If on further testing a problem reaches or exceeds “actionable levels,” dairy producers should seek help regarding water treatment options for their system’s drinking water.

Water treatment options

Water treatment options vary depending on the water quality issue involved. A major difficulty in treating drinking water on dairy farms is posed by the huge volumes of water involved.

Recall that a high-producing dairy cow may consume up to, or even greater than, 50 gallons per day. Multiplying this use over hundreds or thousands of cows quickly results in a staggering daily volume of water that requires treatment.

Thus, one of the best water “treatment” options may be finding an alternate water source free of problems.

Other water treatment options include distillation (too costly), reverse osmosis (RO), ion exchange resin system (traditional water softener employing salt), oxidation + filtration via aeration (often called an “iron curtain”) and hydrogen peroxide (H2O2) injection systems.

Removal of excess TDS and excess sulfate + chlorine usually employs traditional water softeners or RO systems. Reverse osmosis systems remove 80 to 90 percent depending on their design.

Conventional water softeners are effective, but not designed to handle large volumes of water and require an acceptable place to dispose of the brine flush water needed to recharge the system.

Designing a water treatment system that works

Depending on the number of animals served, it may be necessary to design a water treatment system in such a way that large volumes of treated water can be stored for use at times of peak demand.

Oxidation systems are mainly used to remove excess iron from cattle drinking water. The “iron curtain” system employs aeration to convert the iron to a precipitate ferric (Fe+3) form, which is then subsequently filtered from the water.

The hydrogen peroxide (H2O2) system involves the Fenton Reaction which converts iron from Fe+2 (soluble in water) to Fe+3 (insoluble in water) that can then filter out the Fe+3 as a precipitant.

This system injects H2O2 into the drinking water (8 oz. of 35 percent H2O2 per 1,000 gallons of water) and is quite cost-effective. A suitable injection pump costs around $500 and the cost of 15 gallons of 35 percent H2O2 solution is about $100 (enough to treat about 240,000 gallons of water).

When working with water treatment vendors, it is absolutely essential they understand the following items about your farm’s situation.

1. Do they know how much water your dairy farm uses? More than likely your dairy uses much more water per day than the typical water treatment professional is accustomed to.

There is a short paper, “Estimating Water Usage on Dairy Farms,” that helps producers understand the volume of water needed on a modern dairy farm.

The paper also has an accompanying spreadsheet that producers can use to estimate daily water needs on their operations. To get a copy of the paper and/or the spreadsheet, send an e-mail to thomasc@msu.edu.

2. What is the treatment rate (volume/time) of the water treatment company’s system?

Again, your dairy will most likely consume water at rates, particularly at peak demand periods, with which typical water treatment professionals are unfamiliar.

Can their system keep up and provide enough treated water to meet your peak demand?

3. Does the water treatment provider guarantee their system will meet peak demand and reduce the undesirable element or chemical to acceptable levels?

Will their system meet this requirement throughout the expected useful life of the system? Are they willing to provide such guarantees in writing?

4. What is the expected useful life of their system, and what are their system’s maintenance requirements and costs? Who is responsible for maintenance – you or them?

Do they offer a service contract, and if so, what does it cost and what does it cover?

5. What chemicals (e.g., other mineral elements) does their system/method add to the water and at what concentrations?

They may add nothing, but some systems add significant amounts of chemicals (e.g., chlorine) that may cause an entirely new set of problems.

6. Ask potential water treatment providers to allow you to contact other customers that use their system.

Visit these other installations of this provider’s system to determine whether their products, services and warranties are as good as advertised.

Do not do business with any water treatment provider not willing to provide you this information.

We recommend you routinely send samples of your cows’ drinking water to a certified laboratory on a quarterly basis and maintain a historical record of those analyses.

If your water test results suggest that you may need to consult a professional water treatment company to rectify a problem, an appropriate closing message on water treatment methods would be, “Show me the science and the proof of improved cow health and performance before I show you any payment.” PD

References omitted due to space but are available upon request to editor@progressivedairy.com.

—Excerpts from Michigan Dairy Review, Vol. 16, No. 2, April 2011

Craig Thomas is an extension dairy educator withMichigan State University Extension. Email Craig Thomas.