With an automatic milking system (AMS), producers can work smarter rather than harder. They might also enjoy a better quality of life with added flexibility in their schedule and activities – a clear advantage of robotic milking over conventional operations.

A robot operator decides when to start, stop, continue and go home, making it possible to start later and finish earlier in the day.

Labor efficiency of robotic herds in North America can be as high as 12,000 pounds per person per day. But to achieve this, a producer must be organized and diligent.

The success of an AMS operation depends on management style and having the discipline to follow through with daily and weekly routines.

I can’t pretend to tell you that this is absolutely true for every farm and every producer, but instead I can give you an idea of what it’s like to milk with robots and how it will change your workday.

Daily routines

• Feeding – Feeding is the base of all dairy production systems, but here it is the main driver for cow flow.

Producers with robots spend approximately two hours a day feeding their herd. This is the operation’s most time-intensive task, so an automated feed system could be beneficial.

With automated TMR mixing and feed delivery, cows could receive feed at least eight times a day, saving producers 1.5 hours of labor per day.

• Computer-based herd management – Producers should spend about an hour and a half each day working with their herd management system. It’s important to monitor the following data at least three times a day:

- Key performance indicators

- Overdue cows (animals with more than 12 hours since last milking)

- Incomplete cows (animals that milked below a determined threshold in at least one of their quarters during the last milking session)

- Cows at risk of developing or with developed intra-mammary infections

- Cows with high activity or in heat, and cows with low activity or at risk of being sick

• Herd health – Most herd management systems for robotic operations will identify special-needs and attention cows and separate them into a predetermined area. This basic routine can be performed twice a day and take an average time of 1.5 hours.

• Grooming stalls – AMS is all about maximizing the quantity of milkings per station per day. It means lowering time per milking and increasing the time a robot spends milking cows throughout the day.

Teat cleanliness can directly affect stall times – the dirtier the teats, the longer the robot needs to clean them before attaching the liners to dry and stimulated teats. With AMS, the level of teat cleaning can be adjusted at the herd and individual level.

Adding three seconds of cleaning time per teat sounds like very little, but it actually increases the total teat preparation time to 36 seconds per cow per day. In a 240-cow herd, this equals an extra 2.4 hours cleaning teats instead of harvesting milk. In terms of efficiency, this is like losing 20 milkings a day.

Investing 1.2 hours per day to groom stalls twice a day is a best practice for maximizing profitability.

• Fetching overdue and incomplete cows – Every cow is different, and there will always be some animals that are slow, lame or for some unknown reason won’t visit the station as often as needed.

At the same time, incomplete milkings must be promptly addressed so they don’t develop into intra-mammary infections. This routine should be done twice a day, and with proper logistics and layouts it shouldn’t take more than an hour a day.

Keep in mind the cow traffic system can also influence the fetch rate. Typically, free-flow dairies will have more cows to fetch compared to guided cow traffic operations.

• Cleaning the robots and milk room – A producer with robots once told me, “If you take care of the robots, the robots will take care of you.” It was a noble quote as it impacts both robot appearance and performance.

Cleaning the camera lens is as critical as keeping everything clean so regulations and standards can be met – an important part of our business.

• Training new animals – Remember, cows are our customers when milking with robots. To ensure motivation and performance, it is important to develop a consistent training routine for heifers.

There are several training protocols. In an operation with 120 to 240 cows, producers should invest half an hour a day, at least twice a day.

• Changing milk filters – It is important to do this at least three times a day.

• Pushing up feed – To motivate regular cow flow and maximize dry matter intake, cows must have access to fresh feed. Pushing up feed is recommended every four hours.

When combined with delivering fresh feed twice a day, pushing up feed requires a frequency of four times a day for a total of 18 minutes.

• Free time and other tasks – If a producer manages his time and activities correctly, he will have the flexibility to do other things. However, dairy farming is and will remain a demanding job, especially considering some additional tasks related and unrelated to the milking herd, such as weekly routines, youngstock and crops.

Weekly routines

• Bedding – Depending on the bedding system and size of operation, a producer will spend two to four hours a week refreshing the bedding.

Logistics are crucial for this activity, as it impacts not only labor but cow comfort and cow flow.

• General cow movements – Moving cows to different groups or areas takes about one to two hours a week – same as in conventional milking.

• Robot and equipment care – Changing liners and some maintenance routines are weekly tasks. It’s also good to develop a scheduled service routine for different components like, for example, the vacuum systems.

Regular upkeep will help ensure better robot performance and productivity. Investing just two hours per week can be the difference between average and great.

• Vet visits – These are the same as with conventional milking and take one to two hours per week.

• General follow-up and system evaluation – Planning by scenarios is a great advantage, but evaluating and following up is necessary to achieve goals and expectations.

I recommend spending one to two hours a week sharing ideas and discussing alternatives with members of your advisory team, including veterinarians and nutritionists.

• Udder singeing – With the right tools everything is easier; that’s why I highly recommend installing headlocks in robotic milking facilities.

Every animal should be submitted for this routine every two months, but to make it simpler and faster, we should check for long hairy udders every week.

This will ensure attachment accuracy, speed and robot performance. Investing one hour a week is more than enough to keep up.

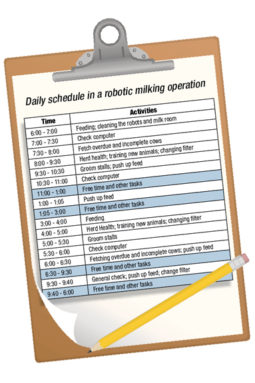

The daily schedule of a well-managed robotic milking operation might look like this (see table).

If you have robotic milkers, it’s obvious that your time won’t be spent milking cows, but you will need to do the other basic chores and some extra routines – making better usage of your management skills.

If spending time with your cows is a problem, robots won’t be your solution. Remember that the result is proportional to the quality of work, so before evaluating success, set your expectations at the right place. PD

Plan to attend the first-ever U.S. Precision Dairy Conference and Expo , June 25-27, in Rochester, Minnesota.

Francisco Rodriguez

Dairy Management Adviser

DeLaval