A growing number of dairy and swine farmers are finding economic opportunities in environmentally friendly manure management.

Through the implementation of renewable natural gas (RNG) facilities, manure can be converted into a valuable commodity and an additional revenue stream for farmers via federal and state-level clean transportation fuel programs.

RNG projects also offer tremendous co-benefits, such as meaningful contributions to net carbon reductions, decreased nutrient loading in waterways, job opportunities, improved odor management, better health outcomes in immediate communities and a higher quality of life for local residents.

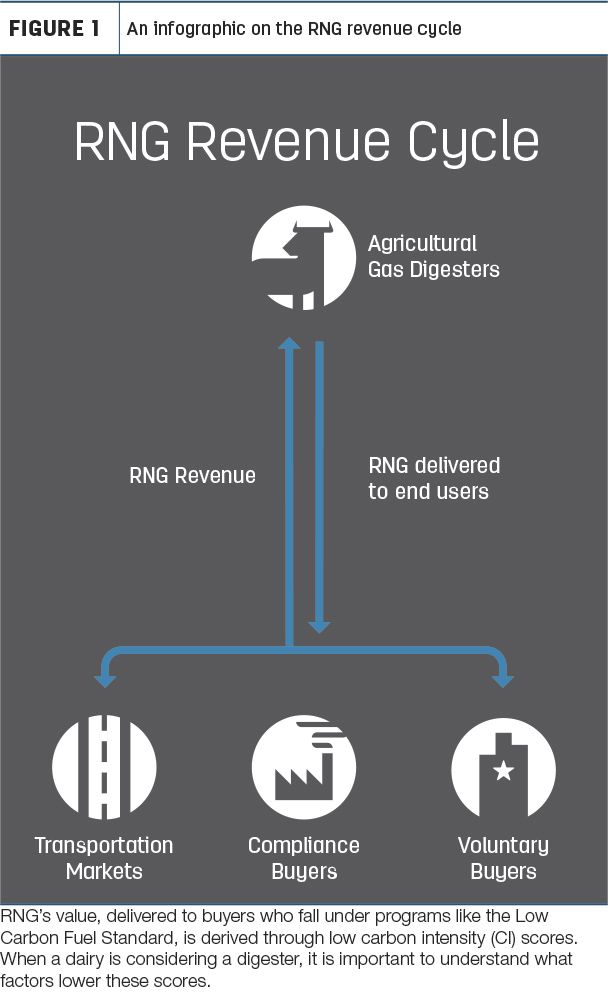

Once an RNG facility is operational, methane generated by dairy and swine farms can be efficiently converted into compressed natural gas (CNG), or liquified natural gas (LNG), and injected into existing pipeline infrastructure. It can then be used in transportation, thermal applications and to generate power. Once utilized as such in California, credits can be created under both the California Low Carbon Fuel Standard (LCFS) market and the federal Renewable Fuel Standard as Renewable Identification Numbers (RINs) (Figure 1).

With more states exploring the implementation of their own similar programs, these markets are projected to increase in the near future.

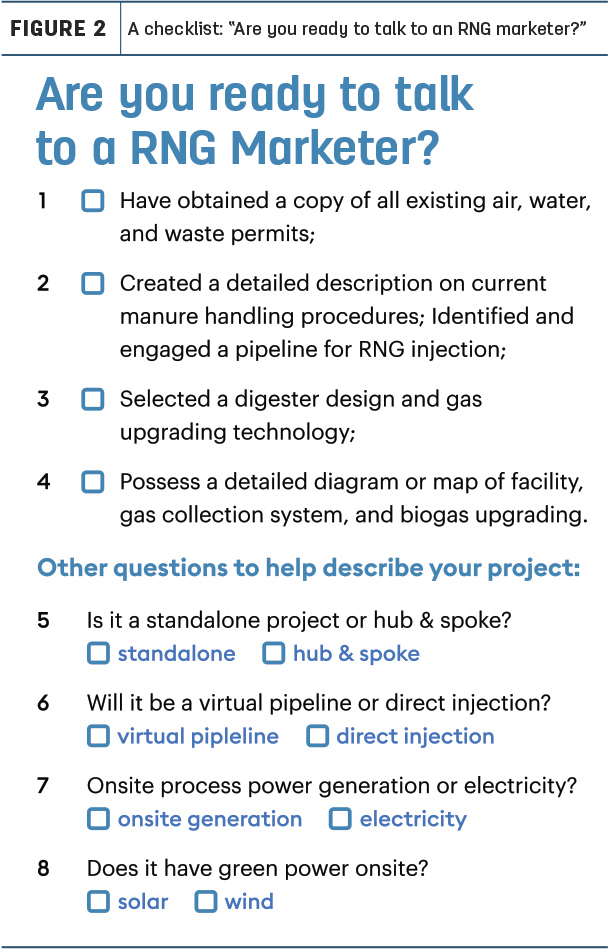

Before embarking on an RNG project, however, it is important to understand the determinants to a profitable venture.

Understanding carbon intensity scoring

Manure management produces greenhouse gases (GHGs), specifically methane and carbon dioxide. Depending on the nature and size of the farm, profit potential lies in the capture and conversion of methane into RNG. To maximize the investment return on RNG projects, the goal is to optimize the carbon intensity (CI) score of the RNG produced. The lower the CI score, the better. Low CI fuels, including RNG, have the highest commodity value across the various transaction opportunities.

CI scoring is a key component of the LCFS regulatory and market landscape and is based on the Greenhouse Gases, Regulated Emissions, and Energy Use in Transportation (GREET) model developed by the U.S. Department of Energy’s Argonne National Laboratory. It models GHG emissions from the renewable fuel’s lifecycle (from feedstock collection through conversion, upgrading, transportation and distribution into the energy pipeline) and compares them with a reference fossil fuel being replaced. The premium value associated with low CI scores is driven by the calculated reduction in those lifecycle GHG emissions.

The LCFS market, in particular, incentivizes baseline emissions mitigation. Optimizing the CI score of any methane capture project comes from maximizing methane avoidance, as measured by comparing a farm’s existing baseline emissions with emissions once the farm has implemented a biogas capture and upgrading system.

To put the opportunity into context, a low CI score assigned to agricultural RNG projects can translate into a commodity with a value 40 times greater per MMBTU than pipeline fossil natural gas sold on the New York Mercantile Exchange (NYMEX), when considering LCFS and RIN credits and the value in the underlying natural gas.

Not all swine and dairy farms offer the same potential to implement an RNG project. Farmers should understand additional key factors, which affect both project viability and potential for CI score optimization.

Manure quantity and storage method

Economic RNG opportunities are mainly focused on larger farms, where high volumes of manure from concentrated animal feeding operations are stored in open lagoons. Neither open-air dry piles nor large-scale deep-pit manure storage lend themselves to RNG generation projects, since manure decomposition in both cases takes place aerobically (with oxygen), which produces carbon dioxide, thereby limiting opportunities for methane avoidance.

In lagoons, however, decomposition takes place anaerobically (without oxygen). The main byproduct is methane, which traditionally vents directly into the atmosphere. A 3,000-plus head dairy farm or 50,000-plus head swine farm equipped with an open lagoon generates a sizable volume of methane and represents significant methane avoidance potential. The process of capturing and upgrading raw biogas into RNG, and eventually displacing traditional fossil fuels (e.g., gasoline or diesel), has significant emission-reduction benefits. These benefits are rewarded with a low CI score, resulting in a higher value of manure-derived RNG utilized under the LCFS program.

Digester selection

The capture of RNG from a lagoon requires capital investment. This starts with an appropriate digester. In warmer climates such as California, Texas, North Carolina and Florida, in-ground, passive covered lagoon digesters –either concrete-lined or otherwise (requiring little more than a heavy-duty plastic cover) – are typical and the least capital intensive for returning a good CI score.

In colder climates, such as Wisconsin, Minnesota or Iowa, above-ground active digesters, which typically add heat and mixing, are more common. Temperature-controlled active digesters will produce methane year-round. In-ground passive systems have at least some seasonality. Adding heat or energy for mixing in active digesters worsens the CI score, but this can be offset if it increases methane production.

Lagoon management

How a farmer manages a lagoon also has an impact on CI scoring. Periodically, a lagoon must be cleaned out to prevent buildup of inorganic solids that don’t decompose. Since upstream solid separation is more common on dairy farms than on swine farms, close attention should be paid to the quantity of volatile solids that don’t end up in the lagoon. This negatively impacts the level of methane avoidance and the CI score.

Project efficiency

Overall project efficiency also impacts CI scoring. This is determined by comparing the amount of methane captured from the digester with the amount converted into pipeline-quality RNG.

Impediments to efficiency range from biogas leakage at the digester (fugitive losses) to processing losses, which may occur during upgrading, such as emergency flaring. Imbalances between inputs of raw methane and output of RNG impair the CI score, highlighting how mitigating losses is crucial to a project’s success.

Farmers can enhance operational efficiency and CI score by incorporating renewable energy inputs into the RNG supply chain. For example, wind and solar energy might be employed in active digesters where heat or mixing is required, offsetting the use of fossil-fuel energy. Likewise, if RNG is transported by road to a pipeline injection point, operating CNG-powered trucks instead of diesel-powered alternatives improves the CI score.

Perhaps most important are efficiency gains through economies of scale. A hub-and-spoke project design is a very effective way to minimize capital and operating expenditures while maximizing the CI score and RNG production. Adding more lagoons –spokes – to a single raw-biogas refining point – hub – is both cost-effective and efficient.

The Milford Swine project in Utah is a prime example of an effective hub-and-spoke model. The project was designed to connect dozens of individual lagoons with a single biogas refining unit via inexpensive, low-pressure piping, keeping costs low and scalability high. All the better, too, if a project is located proximal to a pipeline injection point, which can be found with a call to a local utility.

Though there are many elements to consider, opportunities to convert a farm’s waste stream into a profit center are immense. With lucrative credits available both from California’s LCFS market and the federal RIN market, investment now can likely have a payback period in less than four years, especially considering potential future opportunities in other states.

By taking steps to ensure RNG has a low CI score, the period from investment to return will be shortened and long-term profitability enhanced. Working with experienced partners who understand transportation fuel programs can help minimize regulatory challenges and maximize financial benefits.

PHOTO: This is an aerial view of an RNG operating facility on a dairy farm. Photo courtesy of Roeslein Alternative Energy.