Feeding dairy cows is as much an art as it is a science, and there are several obstacles that can pose challenges to a successful feeding program. One of these challenges is the consistency of the feeds at our disposal.

In order for cows to thrive, it is essential to do everything we can to ensure the quality and consistency of the ingredients we feed.

When it comes to high-protein ingredients, the primary nutrients of interest are metabolizable amino acids, meaning those amino acids that pass through the rumen undigested and can be absorbed by the cow for productive use. Animal-rendered byproducts such as blood meal, porcine meat and bone meal, and feather meal are significant sources of concentrated amino acids and often have amino acid profiles similar to the requirements of the lactating dairy cow.

These ingredients can present tremendous value when it comes to providing cows with both metabolizable protein (MP) as well as specific amino acids to help support production. However, it has been noted that the byproduct nature of these ingredients poses challenges for consistency in both nutrient content and digestibility.

Byproduct variability

As with many byproducts, the variability in animal-rendered byproducts is driven largely by processing differences. For example, the rumen-undegradable protein (RUP) value of blood meal is influenced by the level and extent to which the product is heated. If the product is heated for a longer period of time or at higher temperatures, more proteins are denatured or converted to Maillard products, which are less degradable by rumen microbes, leading to increased RUP.

Too high of temperature or drying for too long can negatively affect the post-ruminal digestibility of the blood meal. The impact of processing can be seen in the differences between spray-dried and batch- or ring-dried blood meals. Spray drying is a gentler drying process where blood meal is dried using air at approximately 200ºF, compared to batch or ring drying, which are carried out at over 300ºF. The RUP of spray-dried blood meal tends to be lower than for batch-dried blood meal. In fact, the low temperatures of spray drying mean that spray-dried blood meal products are not suitable for use as bypass protein sources in dairy cattle.

There are also differences in products based on the species of origin. Ruminant blood meal tends to have a lower crude protein (CP) content and is more prone to contaminants than porcine blood meal. With regards to feather meal, chicken feathers tend to be cleaner and more well processed than turkey feathers. There is variability in this sector as well between different manufacturers and even manufacturing locations. All these sources of variability make it difficult to ensure consistent responses to the animal-rendered byproducts being fed on dairies.

Analytical testing and evaluation

So what should we do about all of this variability? Analytical testing is really the only way to be “sure” of what you are feeding. As stated previously, the key nutrients of interest in high-protein feeds are the metabolizable amino acids. Unfortunately, the wet chemistry analysis of individual amino acids by laboratories is cost-prohibitive, and determining digestibility of these amino acids is even more so. As a result, the current standard in evaluation of protein quality is metabolizable/digestible protein (or nitrogen).

There are two main methods at commercial feed laboratories for this evaluation: in situ (in the cow) or in vitro (in the lab). The in situ method has evolved over time but involves measuring the rumen-undigestible fraction of protein by incubating it in the rumen of a cow for 16 hours, followed by various enzymatic methods of determining the intestinal digestibility of that RUP fraction. The in vitro method was developed by researchers at Cornell University within the last five years and sought to standardize the analysis by removing some of the variability from the in situ assay. The assay is conducted entirely in a single flask in the laboratory. This assay has been demonstrated to work well in plant-based proteins such as soybean meal.

The most accurate method of determining total tract protein digestibility is to assess it directly in the animal. In ruminants, there are several problems with this direct determination approach. These tests involve feeding solely the ingredient of interest and measuring its disappearance. Ruminants cannot be fed single-ingredient diets. Additionally, the rumen microbes themselves create protein, so there is a significant amount of protein unrelated to the ingredient of interest. A widely accepted biological alternative is to evaluate digestibility of ingredients utilizing the precision-fed cecectomized rooster bioassay. Roosters are fasted for 24 to 48 hours, then fed an exact amount of the ingredient of interest with protein excretion being measured to determine total tract digestibility.

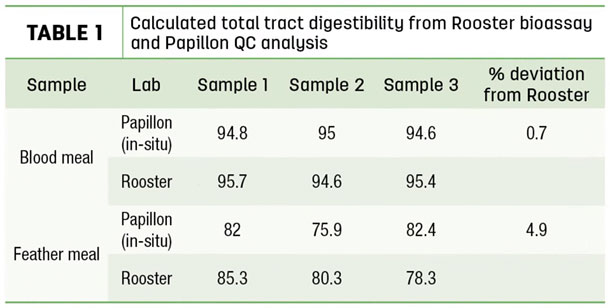

Examples of results for blood and feather meal are listed in Table 1, compared to the in-situ method of determining digestibility used by our company.

These types of measurements are still cost-prohibitive to be performed on a regular basis and leave us with the two commercially available methods discussed previously.

Achieving consistent results

The key to using any method for evaluating the quality of a bypass protein source is to pick an analytical method and lab and stick with it. Familiarizing yourself with the results you receive from a specific lab/analysis combination and how cows respond to those results will eliminate some of the variability in results and enable you to make rank-based decisions on the sources of protein you are using.

Alternatively, considerable time and money can be saved by working with suppliers whose ingredients and finished products are backed by rigorous quality control measures and have guaranteed nutritional values based on consistent analytical testing. For high-protein feeds, animal protein blenders accomplish this task by sourcing ingredients from a limited number of suppliers chosen based on consistent quality control analysis.

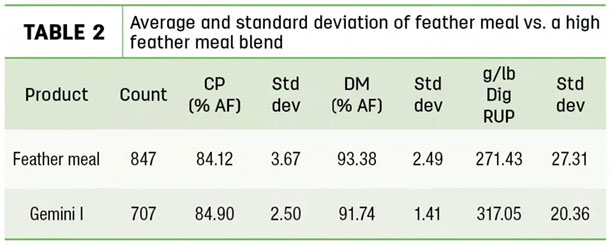

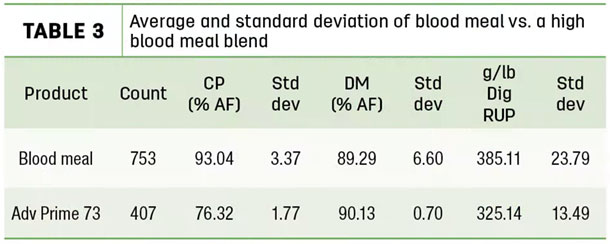

Blending ingredients together helps reduce the variation in the final product that will be included in the ration. Tables 2 and 3 show variation in blended products compared to variation within a single ingredient over the past seven years.

These results clearly demonstrate that blending and quality control can greatly reduce variation of the final product.

The process of selecting quality ingredients from reputable suppliers and blenders, coupled with accurate nutrient specifications in ration formulation programs, can improve cow productivity and efficiency while reducing diet costs, which should be goals on every dairy operation.

References omitted but are available upon request by sending an email to an editor.