Automated technologies – from calf feeding and feedbunk management to milking procedures and herd management – can create efficiency and consistency on your farm.

Take time to evaluate your automated technology options and simulate the results they could bring to your farm and management style.

- Look at each management area on your farm. Where would you like to improve? What will have the most impact on the long-term success of your operation? These answers will direct you to which type of automated technology you should consider.

- Involve your employee team early in the consideration process. Planning and educating are the critical elements of success when adding new technology. Before you consider implementing new technology, explain the technology to your team. Get their feedback and have them share any concerns. If the technology will impact their role on the farm, be clear about how it would change their daily tasks.

- Define your goals. What is the result you want to achieve? What roadblocks could prevent you from obtaining this goal? How could automated technology help? How will you know if you and your team are successful? Set specific, measurable goals for tracking and evaluating the success of new technology. Hold yourself and your team accountable to your goals.

- Simulate the technology. After you have team buy-in and have clear goals, simulate the technology by setting up a trial to experience the results before making a capital investment.

Consider simulating one of these common automated technologies:

Calf feeding

Feeding calves smaller volumes of milk multiple times a day has shown to improve average daily gains (ADG).

Simulation: Implementing a 60- to 90-day feeding trial with more feedings per day allows you to see the benefits of automated feeders before making the capital investment.

Consider implementing a 60- to 90-day feeding trial with more feedings per day to see the benefits of calf automated feeders before making the capital investment. Courtesy photo.

Consider implementing a 60- to 90-day feeding trial with more feedings per day to see the benefits of calf automated feeders before making the capital investment. Courtesy photo.Results: While there is a cost to implement the trial, the result will help decide if incorporating automated calf feeders can yield the same result with greater efficiency.

Feedbunk management

Pushing up feed more frequently has been shown to improve milk production.

Simulation: If you’re currently pushing up feed twice per day, you could implement a trial to push up feed four times per day or every six hours and measure the results.

Results: Whether the results yield more consistent dry matter intake (DMI) or less sorting at the bunk – if the results are there, you could consider an automated feed pusher.

Herd management

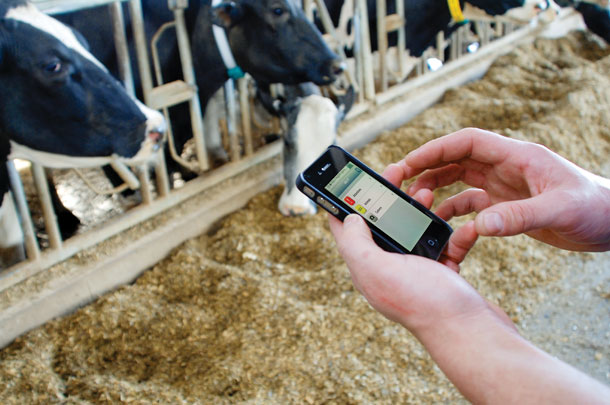

With a plethora of data available, cow monitoring systems provide many avenues to explore efficiency gains. One management area where dairy farmers realize these gains is reproduction.

With a plethora of data available, cow monitoring systems provide many avenues to explore efficiency gains. Courtesy photo.

With a plethora of data available, cow monitoring systems provide many avenues to explore efficiency gains. Courtesy photo.Simulation: You can trial the reproduction payoff by running a pilot for a few weeks – spend at least 20 minutes during early morning, noon and late evening observing for heats to catch more than 90% of the heats in your herd.

Results: By following these heat observation recommendations, most people will find more cows in heat, can identify the cows and breed more timely while simulating the results we see with the incorporation of cow monitoring systems.

Parlor management

If labor or implementing good milking procedures are a challenge, there are tools to help address that, such as automated teat prep and automated post-dipping. These tools make it hard not to get a consistent result every time since the machine is doing the work.

If labor or implementing good milking procedures are a challenge, consider test driving automated teat prep. Courtesy photo.

If labor or implementing good milking procedures are a challenge, consider test driving automated teat prep. Courtesy photo.Simulation: The best opportunity to test these types of tools is by working with your local automated equipment dealer to demo the product for a short period of time and evaluate the results.

Results: By completing the demo, you’ll have real data to reflect on and feel confident in deciding on whether to purchase.

On-farm testing is not the only way to evaluate the benefits of new technology. Your local automation equipment dealer can connect you with other dairy farmers who have implemented these technologies and are seeing results.

After your technology test drive or conversations with other users, work with your employee team to decide if this technology makes sense for your operation.

The most successful implementors of automated technology continually evaluate the results and stay focused on the goals. With careful planning and evaluation, you’ll reap the benefits of cutting-edge automation technologies by reducing stress levels for you, your cows and your employees.

Automated technologies can help you create consistency, increase productivity and reduce labor. Work with your local milking equipment dealer to find the best automated solutions for your dairy.