Byproduct feeds are feed ingredients that have had nutrients extracted for human or commercial applications. Examples include soybean meal (oil removed for industrial and human food uses), fuzzy whole cottonseed (fiber used for clothing) and corn distillers grain (production of ethanol as a fuel).

Nutritionists refer to byproduct feeds as co-product feeds because the byproduct feed can be higher in nutrient content than the original feed ingredient. An example is corn distillers grain (30% crude protein), while corn is 10% crude protein (CP). Several considerations should be weighed by dairy farmers and nutritionists.

1. What factors should be used when deciding if adding byproduct feeds fit for a specific byproduct feed?

Use the “2P” principles when evaluating byproduct feeds. The first “P” is price. Can you lower your feed costs without sacrificing performance? Progressive Dairy magazine has a listing of byproduct feeds indicating which byproduct feeds are underpriced (good buy) and overpriced (not a good buy) based on nutrient content compared to other feed ingredients. Breakeven prices can be based on all nutrients or consider carbohydrate, protein or fiber value. Reports can indicate breakeven prices by regions in the U.S., indicating which byproduct feed may be more price competitive due to location of byproduct production and/or transportation costs. Other reports list the cost per unit of energy, metabolizable protein (MP) and effective fiber. The second “P” represents positioning the byproduct in the current diet to improve performance (could improve rumen health, change rate of feed passage, reduce low-quality forage in the current diet, increase milk components or raise milk yield). No breakeven feed prices are listed, as readers can find these values in prior Progressive Dairy articles.

2. What could a byproduct feed contribute to the diet?

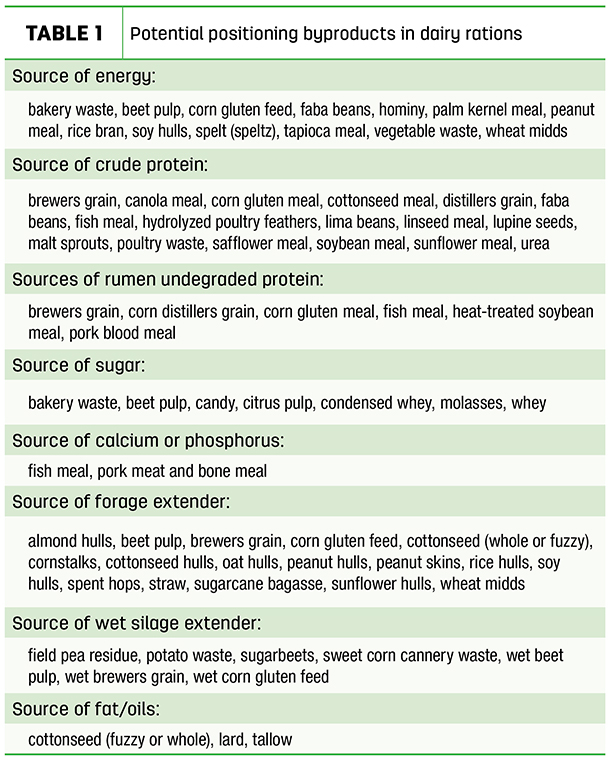

Table 1 lists several nutrient groupings that could be considered. Some byproduct feeds can fit in more than one category.

Depending on where your dairy herd is located, the byproduct can be limiting. For example, almond hulls in California dairy herds and citrus pulp in Florida could be good fits. Transportation costs can be a factor, especially for wet byproducts containing over 60% water (calculate the cost per ton of dry matter delivered). Some of the byproduct feeds listed in Table 1 have restrictions on the amount that can be added due to level of anti-nutrition factors, such as tannins or gossypol, level of sugar, level of oil and type of fatty acids in the oil.

Depending on where your dairy herd is located, the byproduct can be limiting. For example, almond hulls in California dairy herds and citrus pulp in Florida could be good fits. Transportation costs can be a factor, especially for wet byproducts containing over 60% water (calculate the cost per ton of dry matter delivered). Some of the byproduct feeds listed in Table 1 have restrictions on the amount that can be added due to level of anti-nutrition factors, such as tannins or gossypol, level of sugar, level of oil and type of fatty acids in the oil.

3. What limitations could be a factor with byproduct feeds?

- Quality and consistency of the byproduct feed nutrient level must be monitored and adjusted in the diet.

- Risk of mycotoxins can occur in byproduct feeds during harvest or while in storage conditions (humidity and moisture).

- Shrink (feed losses leading to feed not consumed) can be a problem due to precipitation (rain or snow), wind losses, mixing errors due to particle size and flow, and bird/rodent consumption.

- Inventory control and costs can be a concern when low levels are added to the diet. A semi-load of blood meal can last a long time, risking quality changes during storage. Interest cost is an expense, as most companies want their payment at the time of delivery while the byproduct feed is not fed for several months.

- Wet byproduct feeds can have short timelines before molding and deterioration occur, reducing quality and dry matter intake (DMI). Most wet byproducts should be fed by seven to 10 days from the time of production unless these byproduct feeds ferment during storage, lowering pH and producing organic acids to preserve the wet feed.

- Changes in quality while stored due to weather risk, mold formation or heating.

- Testing of byproduct feeds to adjust diets are needed when variation occurs in the byproduct feed.

- While byproduct feeds may contain significant levels of NDF, the physical form may not contribute effective fiber (cud chewing and forming a rumen layer) due to processing and pelleting for denser weights, lowering transportation costs. Fuzzy cottonseed retains its effective fiber value unless it is pelleted or ground.

4. What items can be considered when using a byproduct feed?

Heat stress could be a factor to maintain DMI and rate of passage when forage quality is marginal, generating more heat increment. Replacing low-quality forage with high neutral detergent fiber digestibility (NDFD) can reduce heat production, provide more nutrients and improve DMI. Check on the NDFD values, as they can vary greatly (from oat hulls to soyhulls, for example). Adding sugar (6% to 8% of the ration dry matter) can improve feed intake, NDFD and milk components. A shortage of forage may exist due to drought, winterkill of legumes or cereal grain forages, or poor harvest conditions.

5. Should I purchase byproduct feeds directly from the source of production or through a feed mill?

To improve uniformity, byproduct feed mixtures can be purchased and blended through a local feed mill. Several advantages can be realized.

- Ribbon mixers can achieve more uniform mixing than on-farm units.

- Quality control is shifted to the feed mill.

- Ration balancing based on byproduct feed changes can be handled by the feed mill.

- Large quantities of each byproduct are not purchased to be stored on the farm. Purchases are made on an as-needed basis.

- A blended pre-mix of several byproduct feeds, protein sources, mineral and vitamin pre-mix, and additive can be added on the farm in 4-to-8-pound blended mixes, reducing weigh errors, decreasing mixing time and providing a larger uniform mix to be blended with on-farm forages and other feeds.

- Feed mills may be able to purchase byproducts more strategically and in larger quantities than a dairy farmer, resulting in lower feed costs.

The bottom line is: Byproduct feeds should optimize nutrient balance to meet dairy cow needs while reducing feed costs.