Is it OK to just feed cows, or does it matter what nutrients are fed? Think of it this way: We work to reduce variation during feeding, for both consistent ingredient and nutrient delivery.

Why would we not buy ingredients to also manage nutrient content and consistency?

Nutrient delivery to cows has always been important, and as today’s dairy managers enhance milk component output and efficiency, a focus on supplying high-quality nutrients in dairy rations will continue. Higher cow performance also warrants continued improvements in delivering rations with consistent levels of high-quality nutrients.

Dairy producers and feed managers strive to reduce feeding errors to provide a more consistent nutrient supply to the herd. Nutrition professionals can support those efforts by helping producers make quality nutrient decisions through byproduct ingredients.

Both nutritionists and producers understand the foundation of meeting the nutrient requirements of cows begins with forages available on the farm. From there, ration models use an array of ingredients to formulate a diet that meets a herd’s nutrient requirements. With only a few exceptions, most ingredients used to complement the nutrient supply of on-farm forages are byproducts from other food or fiber industries.

Previous articles in Progressive Dairy discuss key factors around utilizing byproducts such as storage, logistics, shrink and such aspects. We will not repeat those quality articles. Another article discussed the concept that dairy cows are flex-fuel animals. More specifically, the rumen of a dairy cow can ferment a variety of different carbohydrates (sugar, starch and fiber), converting them into nutrients that support high levels of production.

This article will discuss points around merging those concepts and highlight the value farms can capture by closely evaluating the nutrient content of the byproducts used in rations.

Nutrient variation, value pricing and your herd

Each dairy farm is unique regarding their daily milk production and level of components. Just as dairy farms differ slightly in their production systems, so do processing facilities that produce byproduct feeds used as nutrient sources to feed cows.

For example, while two dairy farms may vary in milkfat content by two-tenths of a percentage (i.e., 3.8 and 4), so can grain processing facilities vary in their efficiency at removing fat from a soybean or canola seed or starch from a corn or wheat kernel. In milk component pricing markets, dairy producers certainly know those two-tenths of milkfat can have a significant impact on their pay price. Similarly, the different results from grain processing facilities can alter income generated from their primary product – with a secondary effect of altering the nutrient content of byproducts that find their way into dairy rations.

As a byproduct buyer, a dairy farm that shrugs off the small differences in nutrient content in their byproducts could miss an opportunity to capture value.

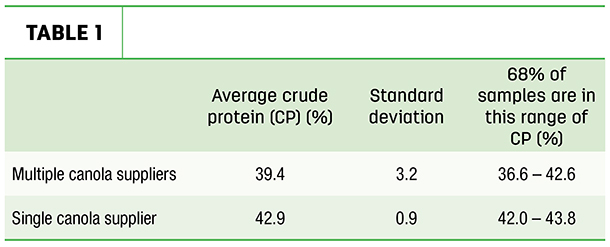

Table 1 compares variation in the nutrient content and consistency of multiple canola suppliers to a single canola supplier.

When reviewing data from a few randomly selected canola suppliers, we see the average crude protein (CP) content was 39.4% but 68% of samples had CP content between 36.6% and 42.6%, while the single supplier had both a higher-than-average CP content and a lower standard deviation – meaning that the range in CP for that supplier was lower than the group put together. This example shows the opportunity feed suppliers and dairy farms have to manage nutrient variation and deliver more consistent nutrient supplies to cows.

For a dairy farm, working with a single supplier can be a good decision compared to receiving loads of what is described as the “same” ingredient from multiple suppliers. Still, not all facilities that produce the same byproduct achieve the same level of nutrient consistency in the byproduct. Further, and perhaps more importantly, care should be taken to select a supplier that provides the most valuable nutrient supply for your ration.

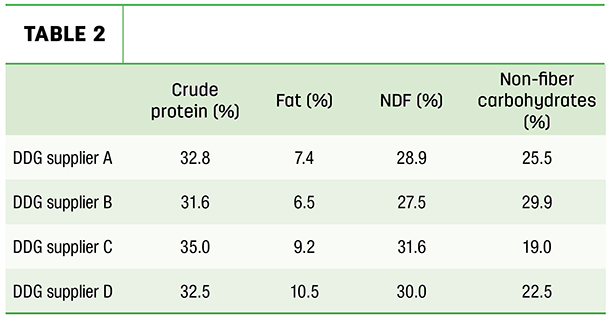

Table 2 shows the nutrient content of four different dried distillers grains (DDG) suppliers.

Dried distillers grains is often known as an ingredient with variable nutrient content, but this statement is misleading. Individual DDG suppliers often produce products with low nutrient variation and, in turn, a very consistent byproduct. Process differences between ethanol plants results in the DDG byproduct varying in nutrient profiles, and that contributes to the assumption that DDG are inconsistent. The differences in nutrient profile between DDG sources are noteworthy when it comes to dairy rations.

An example is shown in Table 2, which gives nutrient information from four different DDG suppliers. These DDG suppliers range in CP content by over 10%. By way of comparison (data not shown), soybean meal sources tend to have a narrower range of difference in CP while also having a higher CP content, resulting in a CP range of only 5% to 6%.

Looking more closely at the nutrients provided in Table 2, we see that DDG is not only a mid-level protein source but also contributes non-fiber carbohydrates (NFC) and neutral detergent fiber (NDF), which carries a high digestibility. Furthermore, DDG fat level can also be a significant factor that determines a DDG supplier’s value.

Earlier in this article, I mention that farms can capture value by focusing on nutrient content of byproducts. Ration software packages generally have an optimizer function that lets the computer do thousands of math calculations, in seconds, which helps the nutritionist select cost-effective ingredient combinations to meet the ration’s nutrient requirements. A key point here is: Every ration situation has a different scenario, and the best answers for one ration may not be for another. Nutritionists will use these software functions to determine which ingredients are a value fit for the diet. To demonstrate this functionality and the impact small differences in nutrient profiles between DDG suppliers can have, I offered each of the four DDG options from Table 2 to the same diet within our company’s system.

When formulating the diet, the system pulled one DDG source into the ration and didn’t use the others because its nutrient profile fit with the other ingredients available in the diet – and therefore was a better value to meet the diet’s nutrient requirements. The system also provides statistics regarding the value of each of those DDG sources and showed a $35 per ton difference in the value of the four DDG suppliers. To describe this in more detail, the “best” DDG for this diet would have been displaced by another DDG if the prices were $2 per ton different, which means those two sources are very similar in value. However, the “worst” DDG for this diet would have to be priced $35 per ton cheaper than the first to be a valuable component. If the farm were to purchase the DDG with the worst nutrient profile, they would have experienced a nutrient value loss of approximately 6 cents per head per day ($35 per ton times 3.5-pound feeding rate). Further, it is likely the nutritionist would need to make diet adjustments to compensate for changes in performance.

To circle back to the flex-fuel concept, we notice in Table 2 that two DDGs are relatively low in NFC, while the others are lower in NDF. If that same diet were to be formulated with a different focus on NFC and digestible NDF levels, then a different DDG becomes the best value for that diet, and the range in value between those DDG sources becomes only $15 per ton.

In summary, the need to be precise with nutrient supply becomes greater as dairy herds achieve higher levels of component production. Considerable portions of dairy rations consist of byproduct ingredients, and understanding the nutrient content of those ingredients is impactful. Some of that impact can be captured when considering the full nutrient profile of the ingredients and the flex-fuel capabilities the rumen has to offer.