You’re going to build a robot barn. Congratulations! Now begins the fun of drafting a barn design that helps you successfully manage your herd.

You may be thinking, “Why do I need help to manage my herd? I’m already doing that well.” The fact is: Regular herd management activities need to be handled differently in a robot barn. Why? Because you are no longer moving the whole herd out of the barn at one time.

Some activities you now need to consider managing differently include bedding stalls, scraping alleys, running your footbath, and sorting for breeding and herd checks – just to name a few. Let’s focus on these four areas when designing your layout.

Consideration 1 – Bedding stalls

Bedding stalls can always be a challenging task, but when you have a milking robot it can be even more daunting. In a robot barn, there are always cows mingling in the alleys or lying in the stalls. What are your options?

- Some people still choose to close off one section of the barn at a time to have free, easy access to the stalls. The pro of this option is: The stalls are all open and available, making it quick and simple to move through the barn. The con is: You must handle and move cows – one of the benefits of a robot barn is the lack of cow handling.

- Other people will just work around the cows. This option means you aren’t moving them from pen to pen, reducing the stress on the animals. The downside is that it is more labor, and you are running equipment in with the cows.

- Another option is an automatic bedding robot to drive over or behind the stalls and put bedding into them. This is less stressful on both labor and the animals, plus you can bed more frequently. Be aware, a bedding robot can be challenging to retrofit into a barn, depending on your fan type and position or your barn layout.

The choice depends on how you want to handle your herd and your management goals.

Consideration 2 – Manure alley cleaning

Another common task traditionally completed when cows are in the parlor is scraping alleys. Again, cows never leave their pens in a robot barn, so you need to plan for how to handle this chore. Some common options are:

- Moving cows to scrape alleys. Those who choose this method will move a section of cows and do all of the grooming activities at one time, often bedding during one of these moves.

- Similarly to bedding, others just work around the cows. The same pros and cons apply to scraping around cows as bedding around them.

- Flushing is also an option for robot barns. While this can bring a lot of benefits, it also brings extra challenges in a robot barn such as the cows always standing in the alleys when the water flushes through and creating a curb, so the water and manure don’t splash up into the robot.

- Automatic alley scrapers are a great option to clean multiple times per day and not disrupt the animal housing. They do require routine maintenance to shorten and grease the chains. It’s also best if these are installed during building for easier installation.

- A more recent option is manure robots. These drive through the barn, collect manure and drop it in a dump station. The cows are not moved from pen to pen, and no additional labor is needed for the task of scraping. Keep in mind, the capacity of the robots can somewhat limit the number of times per day you can scrape, and retrofitting also needs to be taken into consideration.

Cleaning alleys and bedding stalls go hand in hand when deciding how to manage a robot herd.

Consideration 3 – Footbath

One of the more challenging considerations to plan for in a robot herd is running the footbath. You should think about how frequently you want to run it, making sure it’s not impacting cow traffic, making sure it’s accessible for filling and emptying, and the amount of labor you want to invest for each bath. A few ways to manage the footbath are:

- Run the bath in a cross-over and move the herd through as a group. In this case, you never impede robot traffic because the footbath is not part of the robot exit. It also ensures that your solution isn’t losing efficacy without having to refill it. However, you do have to manually move the cows, which can disrupt their routine.

- Place a bath in the exit lane of the robot. This option allows cows to continue with their normal traffic flow. It takes a bit more management to ensure all cows go through the bath and the solution maintains efficacy for the entire herd. If you choose to place the bath in the exit lane, be sure to move it far enough away that the footbath solution isn’t splashing back on your robot equipment. One idea when building a robot barn is to pour a concrete bath that cows must always walk through when leaving the robot. By having a permanent fixture cows walk through multiple times a day, they are less likely to have hesitations with going through the bath when the solution is in it.

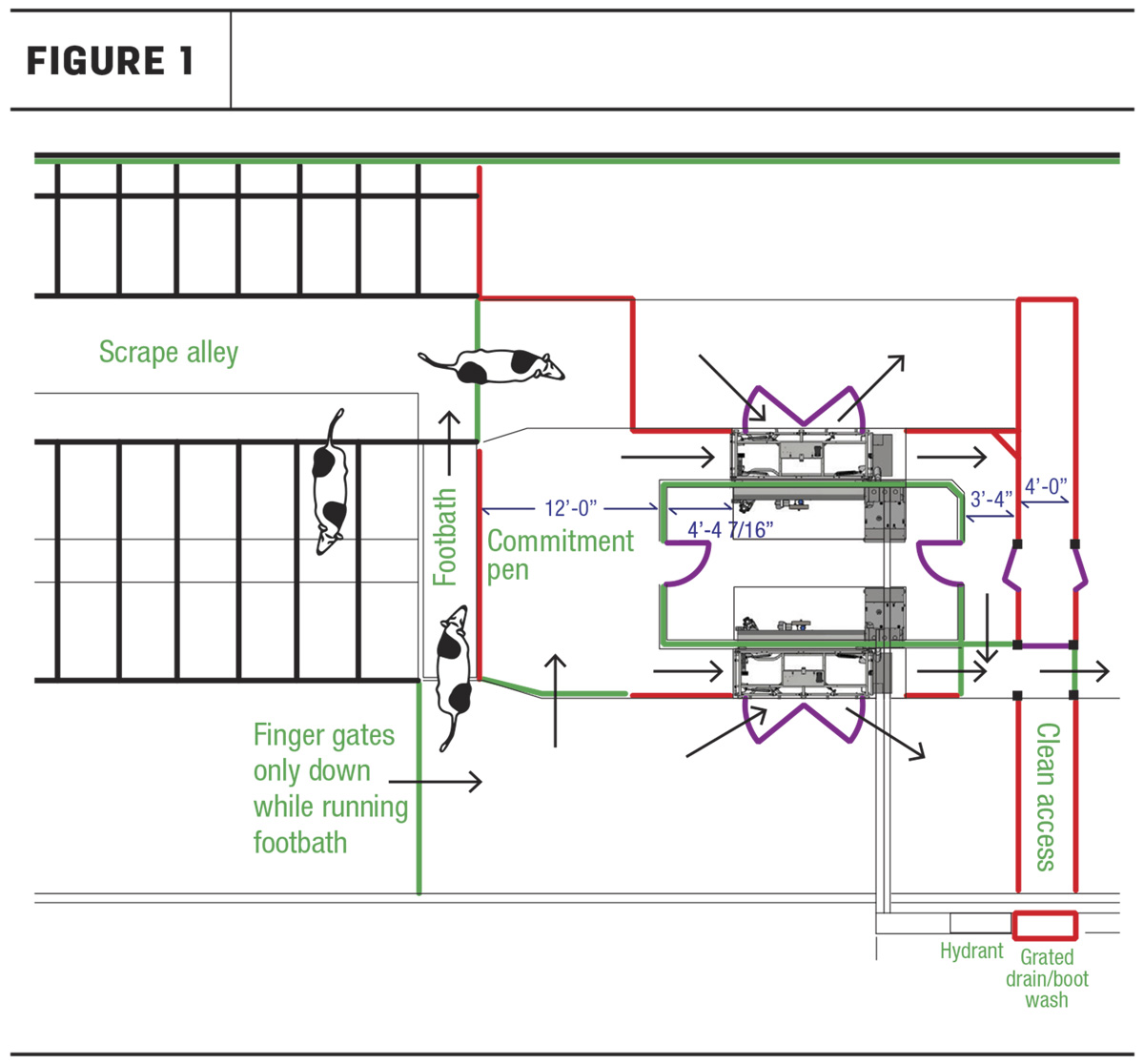

- Another creative solution is to create a secondary “commitment pen” that is only implemented on footbath day. One-way finger gates can be installed to keep cows from returning to the stalls after milking without first going through the footbath positioned behind the commitment pen (see illustration). This is a great option for layouts with short exit lanes to still have an automated footbath option.

Consideration 4 – Sorting activities

Sorting activities, such as hoof trimming and herd check, can actually be simplified with a milking robot. We often recommend a sort pen for robot barns. Even if you plan to move sick or special-needs cows to another facility, having a sort pen makes many management activities much easier.

On hoof trimming day, for instance, we can quickly have the robot create a list based on a set of parameters, then sort those cows to a separate pen as they visit the robot. You may still need to fetch some and move them to the robot; however, many will naturally make it to the hoof trimming area over the course of time the trimmer is on site.

Breeding is another activity in which sorting can be helpful. You are often already using your management software to decide which animals are in heat and when to breed them. When you find a cow you plan to breed later that day, you can mark her to be sorted by the robot, then breed her in the sort pen. Another option is breeding in the stalls. Cows in a robot barn are often much quieter than cows in a traditional freestall barn, so breeding cows right in the stalls is a very easy option.

Herd management in a robotic milking facility is very different from the traditional approach to handling cows. Planning ahead to address some of the key differences can help you design a barn that will work best with your herd management and lifestyle goals. Whether you are retrofitting your existing barn or building from scratch, be sure to work with a trusted consultant who can help you consider all of your options and lay out a barn plan that will set you up for management success.