In recent years, biochar has grown in popularity due to its wide applications in agriculture and carbon crediting. As a result, the biochar market is expected to continue to grow in the coming years.

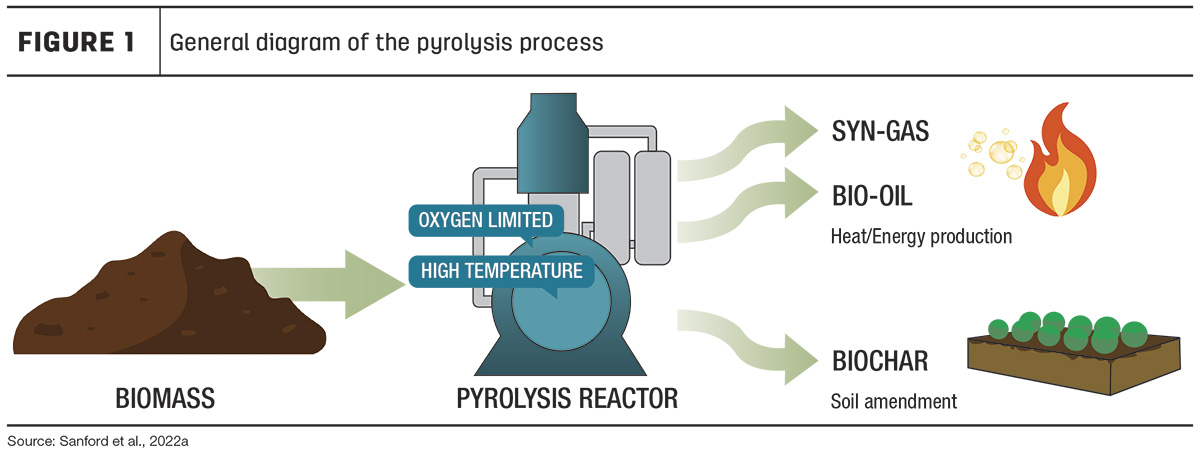

Biochar is a carbon-rich product resulting from a process called pyrolysis, where biomass – such as wood or agricultural resides – are thermally treated at high temperatures under an oxygen-limiting condition (Figure 1). This process results in syngas and bio-oil, fuels that can be used for heating or energy production and a solid product – known as biochar. Biochar has unique characteristics, such as high carbon content, low density (5 to 20 pounds per cubic foot), high porosity and the ability to bind with some nutrients and minerals.

These characteristics vary depending upon what the biochar was produced from (the feedstock), the temperature it was produced at (somewhere between 660ºF to 1,650ºF) and the time it was in the reactor. Studies have shown that when applied as a soil amendment, biochar can sequester carbon, improve soil fertility and reduce nitrate leaching – among other crop production and environmental benefits.

Biochar production systems have primarily focused on using wood-based biomass from the forestry industry. However, there are numerous opportunities for converting agricultural residues, such as corn stover and manure, to biochar. There is an opportunity for biochar to be incorporated into livestock production systems with a focus on manure management.

Converting manure to biochar

Manure is a great asset in agricultural production, as it contains the plant-essential nutrients needed for crop production. However, in some areas of the country, livestock production systems produce more manure nutrients (particularly phosphorus) than are agronomically needed for local crop production. This has resulted in the industry searching for solutions and embracing new, innovative technologies to make it more feasible to move manure nutrients farther from the farm.

Manure solid-liquid separation systems are one technology used to separate manure into two different streams, a liquid and a solid. The solid material contains a portion of the nutrients but has a lower density – due to less water. It can be used for bedding or can be land applied for agronomic purposes. Due to the lower density, it can be feasibly transported farther distances. However, challenges still remain in areas of the country with high livestock densities to transport the manure nutrients where they are needed most.

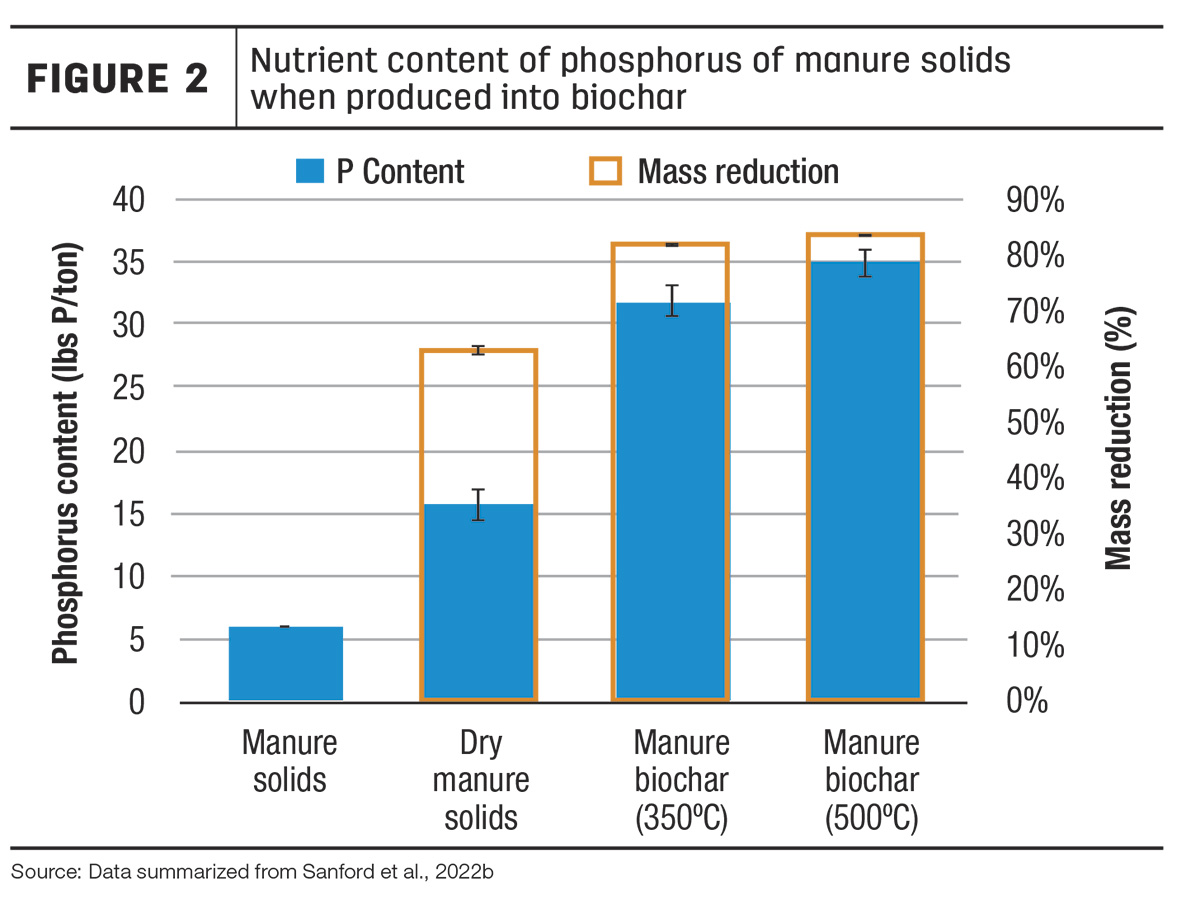

Converting manure solids to biochar could further reduce the mass by 40% to 80% and the volume of the manure solids, resulting in a low-density manure-based product. A complete recovery of manure phosphorus is achieved through pyrolysis. The resulting biochar product can have a phosphorus density (pounds of phosphorus per ton of material) over six times that of the original manure (Figure 2). However, over half of the nitrogen is lost during the process due to the high temperatures and nitrogen volatilization.

Pyrolysis could be a potential method for densifying manure phosphorus to reduce transportation costs. However, a question that is commonly asked is, “Will the phosphorus in the biochar be available to the crops?” It is an excellent question for those wanting to move manure phosphorus where it is needed. As biochar is known for its ability to sequester carbon for long periods of time in the soil, it is a valid question to ask if the same would happen to phosphorus. Unlike carbon, phosphorus is relatively available in biochar. A recent study found that when applied to the soil, manure-derived biochar provided similar available phosphorus over time as unprocessed manure solids when applied at the same phosphorus application rate (pounds of phosphorus pentoxide per acre) (Figure 3).

Challenges for manure-derived biochar

While manure-derived biochar may be an excellent addition to the manure processing toolbox for densifying phosphorus, it does face challenges for industry adoption. Incorporating biochar into manure processing systems will require additional technologies. Most livestock facilities deal with liquid (1% to 7% dry matter), slurry (8% to 12% dry matter) or semi-solid (13% to 19% dry matter) manures. Generally, for pyrolysis systems to be economical, the biomass’s dry matter content should exceed 70%. For pyrolysis to be used on manure, it would require solid-liquid separation to remove the solids, which would need to undergo drying to further reduce the moisture. Many farms have solid-liquid separation systems, but drying is not as common. In addition, the system itself would be expensive. The capital investment would likely be similar to the installation of anaerobic digesters. In the years to come, this may become more feasible with the rising interest in biochar and carbon credit projects.

Overall, the conversion of manure to biochar has the potential to be another tool for manure management systems. The possibility of converting manure solids into a low-density product with phosphorus fertilizer potential will be of interest to the industry and other stakeholders. Many obstacles will need to be overcome to make it more feasible. But with the recent boom in anaerobic digestion system installations and interest in carbon credits, the potential for on-farm biochar production may not be far off.

References omitted but are available upon request. Click here to email an editor.