The push for environmentally sustainable agriculture has sparked a lot of interest in anaerobic digesters that can convert manure into biofuel. According to the EPA, a total of 322 on-farm systems were in operation in the U.S. at the end of 2021, including 50 that started operating that year.

Dairies are in a unique position to take advantage of this opportunity, but the biggest obstacle to more widespread adoption of biodigesters is their cost. An on-farm anaerobic digester can cost upward of $1 million dollars, so it is not surprising that the dairies that operate one tend to have large herds.

All that is about to change for North American dairy farmers. Smaller systems will soon be available – and affordable – for dairies with smaller herds. They cost a fraction of the large biodigesters commonly in use.

In the United Kingdom, a system has been developed that captures fugitive biogas released from slurry and converts it to usable, fuel-grade biomethane, which can either be compressed or liquified. The system can be installed on both new and existing lagoons. In Europe, the system is already used on farms with dairy herds as small as 150 cows. It is anticipated the gas capture system will be commercially available in North America within the next two years in an effort to address energy independence and carbon-neutral farming.

The system includes a lower membrane for the collection of methane and an upper membrane for storage. It works by collecting the released biogas from the slurry and sending it to a gas filtration system for further processing. The gas filtration system sucks the raw fugitive biogas from underneath the lagoon cover. Once the raw gas goes to the gas filtration system, the biogas is filtered to remove moisture and hydrogen sulfide before being sent back to the storage portion of the membrane. The biogas can then be flared off or siphoned off by the gas filtration system to have the CO2 removed and the biomethane either compressed or liquified to create viable fuel for natural gas engines.

This is scalable and mobile. One system can service multiple slurry lagoons. The gas filtration and compression system can be picked up with a telehandler or skid steer and moved from one location to another.

The biggest advantage of on-farm biomethane production is energy independence. With the help of this technology, even farmers with smaller herds can produce biomethane on their farms and use it to fuel their tractors or other equipment that runs on compressed natural gas (CNG) or liquid natural gas (LNG). These types of tractors minimize emissions but have the same power and torque as their diesel equivalents.

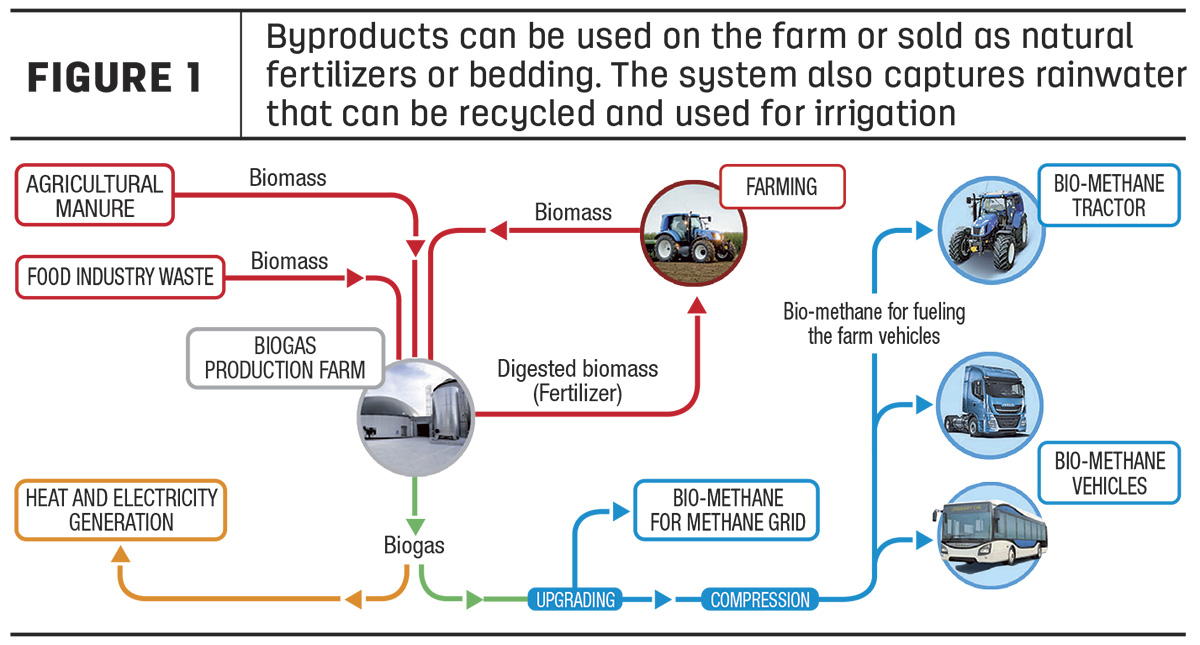

There are additional benefits to on-farm methane production too. By using a biodigester or gas-capture system, farmers can reduce the cost of other inputs. Byproducts can be used on the farm or sold as natural fertilizers or bedding. The system also captures rainwater, which can be recycled and used for irrigation.

In addition to providing fuel for their farm, the gas itself could be supplied to neighbors, providing farmers with an added source of income. And, as a bonus, neighbors will appreciate a measurable reduction in odor.

Together, the methane-powered tractors and the technologies involving on-farm production of biomethane aim to make more environmentally friendly and efficient solutions for agriculture a reality.