Hydrogen is the new thing. There has been a lot of recent press regarding the potential of hydrogen to remove carbon from the energy equation and lead the way to a more sustainable world. This article aims to expound on this idea and how dairy farms can play a role in hydrogen production.

Manure and biogas

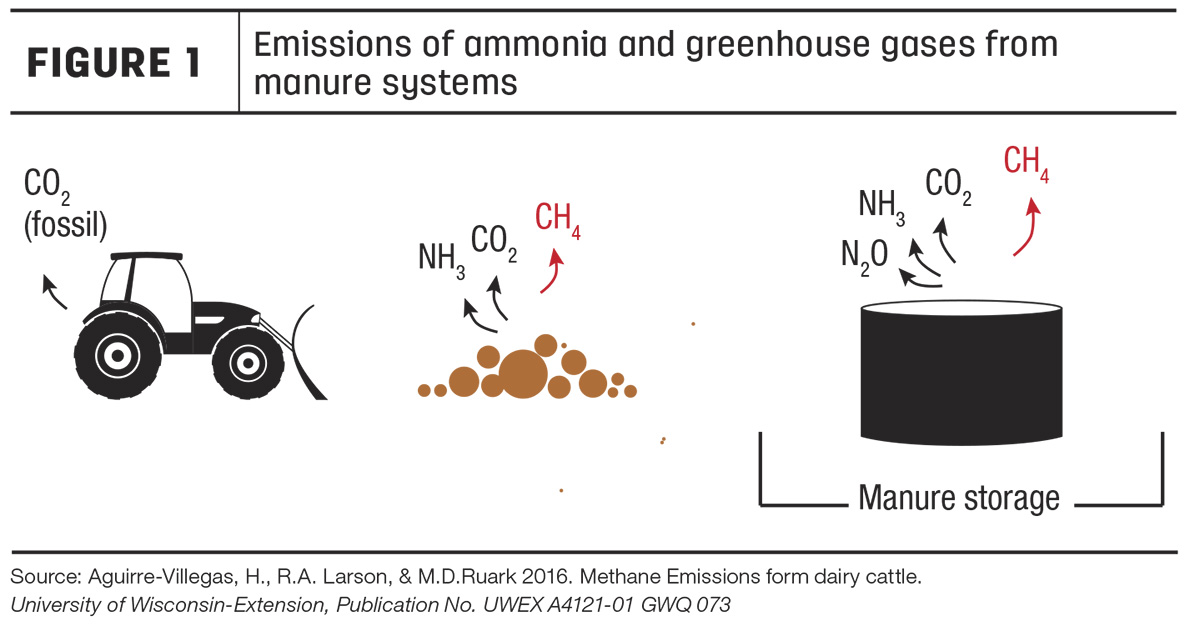

The decomposition of manure is a complex process that results in a variety of greenhouse gases (GHGs), notably methane, carbon dioxide and small amounts of nitrogen-containing compounds (Figure 1). An anaerobic digestion system optimizes for the production of methane, which is not only the fuel but also a potent GHG, thereby tackling two issues at the same time.

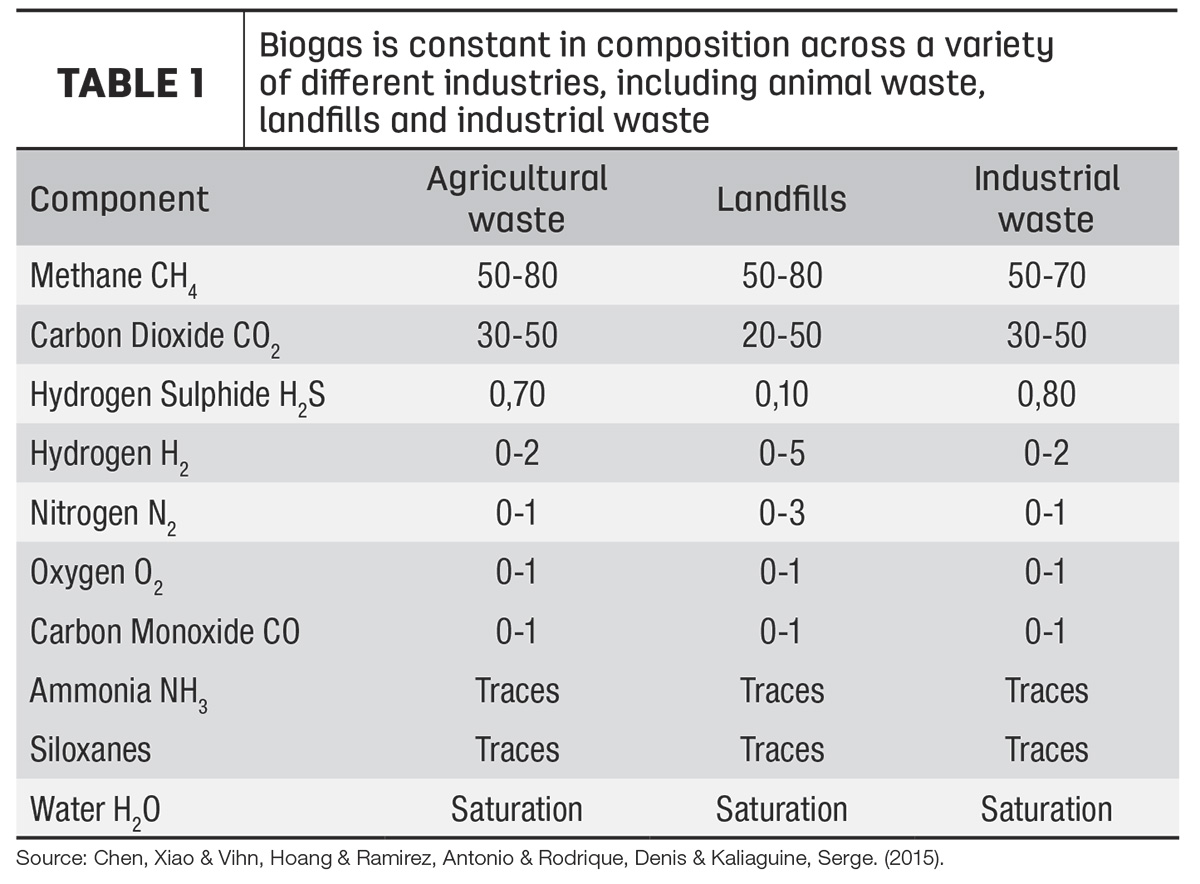

Biogas is surprisingly constant in composition across a variety of different industries, whether the source be animal waste, landfills or industrial waste (Table 1). Roughly half of the biogas is comprised of methane, while the other half consists of carbon dioxide. Typically, there is less than 1% hydrogen sulfide, which is partly responsible for the strong smell of manure.

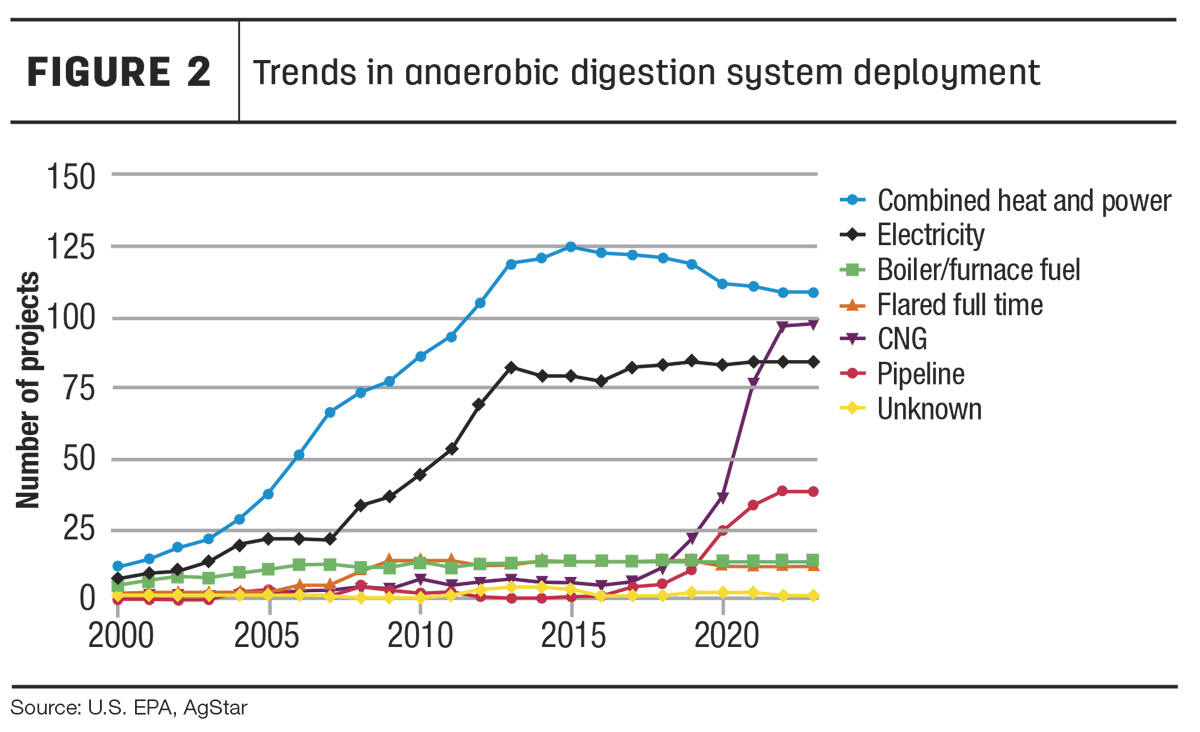

As part of the anaerobic digestion system, raw biogas can be upgraded to renewable natural gas (RNG), which can be burned to produce electricity or heat, injected into a pipeline or used for transportation. According to the EPA, there are currently 343 anaerobic digesters as of January 2023 in operation in the U.S. As we see the trends in anaerobic digestion system deployment (Figure 2), we note that growth in recent years has been driven primarily by transportation and, secondarily, by use in pipelines.

The drivers for the growth between the years 2000 and 2013 have disappeared and new ones have appeared starting around 2017 but, although they appear to have stabilized, 85 are under construction, indicating a strong backlog.

Biogas and hydrogen

Although hydrogen is the most abundant element in the universe, on Earth it is almost never found by itself (except in certain geologic pockets). Typically, energy must be applied to release hydrogen from hydrogen-containing compounds, such as methane or water. When renewable energy is applied to break down water, hydrogen and oxygen are released. This hydrogen is called green hydrogen.

When methane is reacted with steam, hydrogen can be produced along with a lot of carbon dioxide. One pathway involves reacting methane so that it gives up its hydrogen and traps the carbon from the methane. If the carbon is returned to the soil and prevented from going up in the atmosphere, then this is beneficial from an environmental point of view.

All these pathways have their own unique carbon intensity score, and this is an important factor in gauging the eventual profitability of a project. It should be noted that hydrogen production adds to the toolbox and is not expected to be suitable for every operation.

Challenges with an RNG system

- To gain Low Carbon Fuel Standard (LCFS) credits, RNG must be transported to either California, Washington or Oregon. This may not be possible under certain circumstances.

- Not profitable enough unless strong incentives are in place.

- Sends the carbon as carbon dioxide back to the atmosphere, where it can do environmental damage.

Low-carbon hydrogen production systems from biogas

The basics of this approach is that methane is decomposed to carbon and hydrogen. The hydrogen is used for transportation and the carbon goes back to the farm in the form of biochar. Advantages of the hydrogen production system:

- Decreased GHG emissions (negative carbon score)

- Renewable energy for a new transportation industry

- Diversified energy stream

- Qualifies for LCFS (if applicable) and RIN Credits

- Qualifies for Inflation Reduction Act Credit (applies nationwide)

There are no pipelines for hydrogen, so this is going to be a decentralized approach. This technology is at a pilot stage. The hydrogen can be used as on-demand electricity using fuel cells. Of course, wind and solar would compete with this use and are generally more economical than biogas-based systems, but this approach would make sense in cases where wind and solar are not very reliable sources of energy.

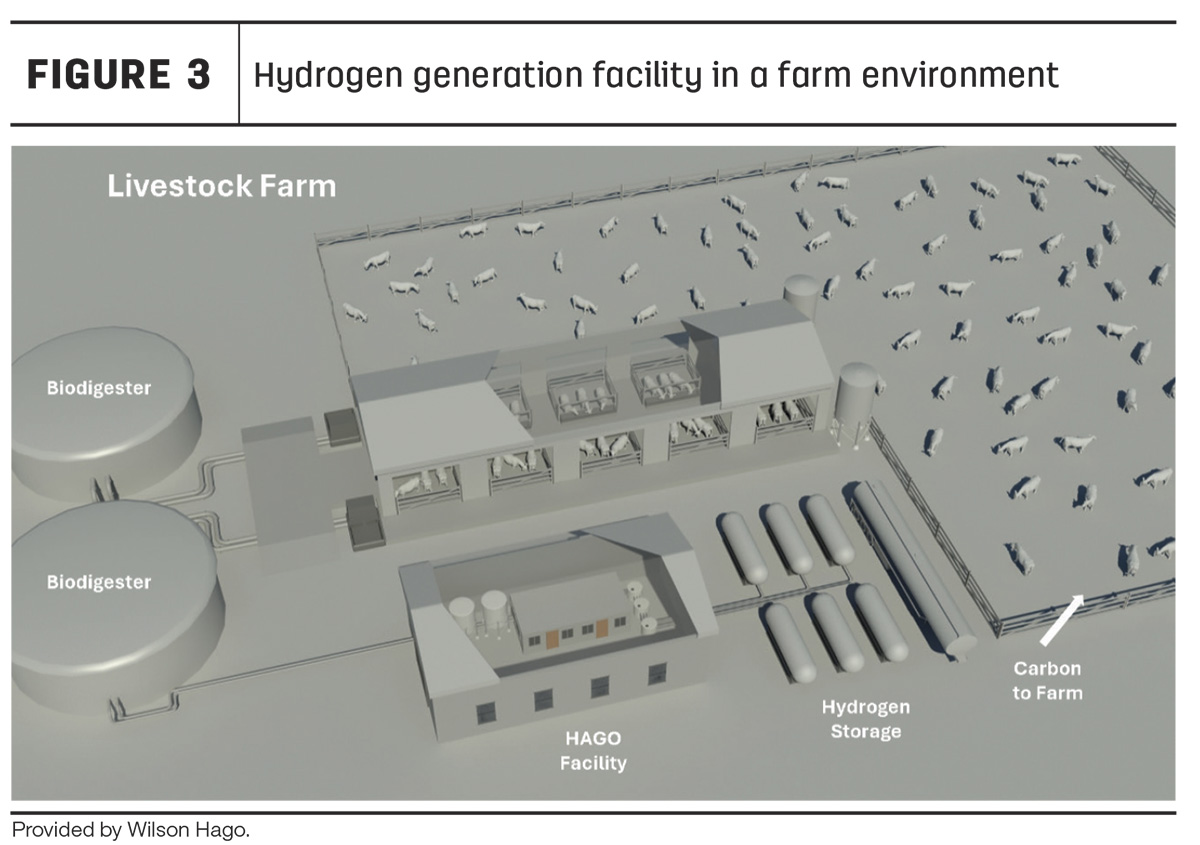

A successful pilot of this technology has been performed at an animal farm in Coalinga, California, and a much larger pilot is being planned at a dairy farm in Madera, California. A pictorial of a hydrogen production facility in a farm environment is shown in Figure 3. Economies of scale we see at around 2,000 cows. These economies of scale can be augmented if food waste is added to the biodigester.

Hydrogen markets

Purchase of new Class 8 diesel trucks at the ports of Long Beach and Los Angeles will not be allowed starting this year and will not be permitted in California starting in 2036. Precedence Research forecast a compound annual growth rate of 43% for hydrogen truck sales for the next decade. Putting hydrogen refueling stations next to farms that can supply hydrogen reduces the cost of hydrogen transport, a major impediment so far in deployment of this technology.

Here is an estimate of different market prices for different products in dollars per 1 million British Thermal Units (MMBtu):

- RNG price $20 to $30 per MMBtu (can exceed $100 per MMBtu on occasion)

- Natural gas price (Henry Hub) $1.50 per MMBtu

- H2 estimated selling price $88 per MMBtu (without incentives)

The net is that biogas and RNG are valuable, but hydrogen can be more valuable. This adds to the long-term income stability for the farm.