With winter behind us and warmer days coming our way, this is the time of year when you should be checking your fans to ensure they are working at their best. Spending the time now on preventative fan maintenance can, and will, save you a lot of trouble and money down the road.

Fan maintenance can be a daunting task, but breaking it down and following a schedule can make it much more manageable. Small daily, weekly and seasonal checks keep fan maintenance manageable. Once you fall behind, it can seem like an insurmountable task.

Here are some tips to keep your fan maintenance simple and easy.

- Creating a periodic inspection checklist helps to ensure you and your employees are keeping things simple while ensuring important tasks don’t get dropped. The list shown in Figure 1 is a good place to start.

- Keep downtime to a minimum with an inventory of small spare parts. Belts, pulleys and bearings are cheap and small. Having them on hand will enable you to do repairs and maintenance quickly, ensuring your equipment is up and running sooner rather than later.

Your local supplier can assist you in ensuring that you have an adequate amount of the right items to make the most out of your spare parts investment.

- Greasing intervals as recommended by the fan manufacturer are important, and your warranty may depend on it. Many automated ventilation controls can track hours of operation so you never miss a greasing interval.

If you do not know or have forgotten what the greasing interval is or the type of grease to use, contact your local supplier for assistance. It’s never too late to start.

- Dirty fans can lose as much as 30 percent of their efficiency, which is why keeping fans, shutters and guards clean is very important. A light cleaning, done a few times a year, with major cleaning once a year in the fall when you begin shutting fans down, will keep them running at peak efficiency.

When cleaning, guards, shutters and louvers can be removed and washed with a pressure washer. A heavy-duty cleaner can be used, but be sure to follow all the instructions and dilution ratios as recommended. Be sure to cover and protect all electrical components from water. Depending on where your fans are located, you may need to use caution to keep bedding dry.

- Track your periodic maintenance. If you have a fan that keeps breaking belts or keeps getting damaged from being hit with equipment, a proper maintenance log will allow you to spot these issues much sooner. Maintenance logs of all activities ensure everyone involved in maintenance at your facility is on the same page. This is key, especially if the fan maintenance is being done by different people on different shifts.

Each fan in your ventilation system plan plays a key role in system performance. If one fan is down, it can affect the rest of the system. Don’t let down fans negatively impact the performance of the rest of your ventilation system.

For example, in a 650-foot tunnel-ventilated barn running 500 feet per minute, you may need 38 72-inch fans. If just two of those fans are not running, the air speed can drop by 15 feet per minute, and the air exchange rate would increase by five seconds. This may not seem like a lot, but you are not getting the performance for which you paid.

If you or your employees do not feel you have the time to do fan maintenance, talk to your local supplier about setting up a service plan. A well-thought-out service plan can keep your fans running at their optimum performance for years.

If you notice that a few of your fans are having more problems than others, there are some basic tools that will help you to troubleshoot, all of which can be found online or at your industrial supply store (Figure 2).

Fan maintenance is key to keeping your fans running like the day they were installed. Ensuring that you keep on top of this ensures your cows have the quality of air they need to be productive and healthy.

Most ventilation systems are custom-designed for each facility to achieve the air speed and air exchange rate requested by the farmer. It’s important that, to get the most return out of your ventilation investment, you need to keep fans clean, greased and maintained. ![]()

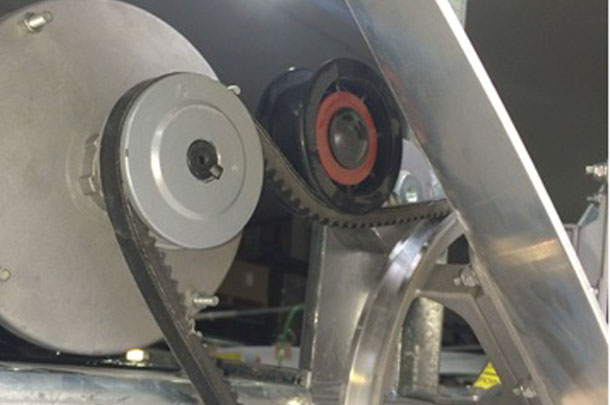

Belt tension:

Adjust belt tension by using a belt tension pulley or changing the belt.

Changing belts:

Keeping an inventory of fan parts like belts, pulleys and bearings makes for quick fixes.

Good belt tension:

Belt tension is critical to maximizing fan performance.

Poor belt tension:

Poor belt tension leads to fans with underperforming air speed and velocity.

Proper pulley alignment:

A fan maintenance checklist should include checking for belt wear, belt tension and alignment of pulleys.

Tightening screws:

Be sure to check and tighten all bolts and screws.

-

Dan Veeneman

- Artex Barn Solutions

- Email Dan Veeneman