Known more for turkey production than dairy farming, the rolling hills of southwest Indiana are also home to the four dairies featured on the 2015 Kentuckiana Dairy Exchange. This event was organized and promoted by the University of Kentucky and Purdue University Extension, Indiana Dairy Producers and the Kentucky Dairy Development Council.

The high heat and humidity didn’t keep the nearly 130 dairy producers and industry representatives from across Indiana and Kentucky away from this annual gathering July 28 and 29. The dairies ranged in size from 200 to 1,250 cows and focused on genetics, robotic milking systems and agritourism. Despite differences in size and management style, all discussed the challenges and opportunities of bringing the next generation back to the farm.

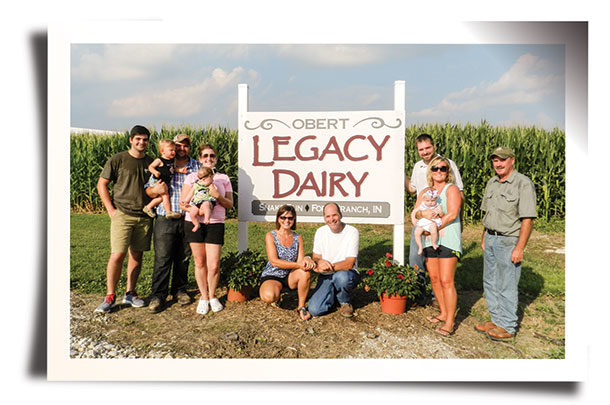

Since 1839, six generations of the Obert family have raised livestock in Gibson County, Indiana. The family built and began milking at Legacy Dairy in Fort Branch in November 2010 and is currently milking 800 cows. They previously operated a smaller dairy farm nearby before expanding and moving the herd.

They are starting to think about transitioning assets and responsibilities to their three sons – Wes, Klint and Mitchell – and each continues to acquire more management responsibilities.

“It’s a business, but it goes so far beyond that,” owner and Indiana Dairy Producers President Steve Obert said. “It’s about multiple generations working together as a family.”

Rauscher Farms Inc., in Huntingburg, Indiana, welcomed the next generation back to the farm in 2013. Dan Rauscher worked off the farm in construction management in Washington, D.C., after graduating from Purdue. He now is involved with their breeding and genetics program as well as the crops, while his father, Mark, works with the nutritionist and breeding the heifers.

They are seasonal in their breeding program and freshen approximately 80 percent of the herd in September and October, accounting for nearly 100 calves on bottles during the fall. This stretches their labor force thin during the already busy harvest season.

They said they try to time breeding and calving so they don’t have cows freshening between Christmas and March and between May and August. This allows time to finish things up and for employees and family members to take vacation time.

Brothers Raymond, Duane, Dale and James Koester operate Koester Brothers Farms Inc., and Diamond K Dairy in Wadesville, Indiana, where they are utilizing robots to manage their herd of approximately 200 cows. In 2012, they built a new freestall barn and installed four Lely robotic milking units.

Their goal in building this new facility was for a small expansion with room for more expansion later if desired, they said.

They also have a Lely Juno feed scraper and automatic alley scrapers. Cows wear collars with a microphone in it that rests against the cow’s neck and can tell when the cow is chewing or eating, and pedometers measure activity levels.

“We installed robots because of the labor situation and for the next generation,” Duane Koester said. “Besides family labor, we only have one full-time and one high school student that work for us. We also wanted to provide a place for our kids to come back to the farm if they choose to do so.”

“We installed robots because of the labor situation and for the next generation,” Duane Koester said. “Besides family labor, we only have one full-time and one high school student that work for us. We also wanted to provide a place for our kids to come back to the farm if they choose to do so.”

Brian and Ranell Rexing’s kids are young, but they see the agritourism side of the business as a place to grow and bring them onboard if they are interested in later years.

Visitors of all ages can experience farm life at New Generation Dairy in Owensville, Indiana, and learn where their milk comes from. Brian and Ranell built New Generation Dairy in 2008, where they employ 25 people and milk 1,250 Holstein cows three times a day.

“As farmers, sometimes we are afraid to tell our story, and we have such a great story to tell,” Brian said.

Meals and traveling between farms provided opportunities for producers from the two states to network with each other.

“The conversations, sharing of ideas and relationships built between producers and with industry representatives are some of the most valuable parts of this tour, and a lot of that happens on the bus,” Indiana Dairy Producers Executive Director Doug Leman said.

“The conversations, sharing of ideas and relationships built between producers and with industry representatives are some of the most valuable parts of this tour, and a lot of that happens on the bus,” Indiana Dairy Producers Executive Director Doug Leman said.

The University of Kentucky’s Drs. Jeffrey Bewley and Michelle Arnold presented information about Cow Signals during the evening program. Cow Signals is a way to look at your dairy and answer those “why” questions, Arnold said.

“Using Cow Signals can help prevent problems and ‘owneritis’ (or tunnel vision) by carefully observing and learning from the body language of the herd,” Arnold said.

The program focuses on the six freedoms of the pasture that cows desire: feed, space, water, light, rest and air.

“By reading the cow’s body language, producers can look at the entire cow and figure out if something isn’t right and then make changes to their management as needed,” she said. PD

Kimmi Devaney is a livestock specialist with the Indiana State Department of Agriculture. She also writes an agricultural blog.

PHOTO 1: The Obert family expanded their herd and opened Legacy Dairy in 2010. Today, their three sons are transitioning into management roles.

PHOTO 2: Nearly 130 producers and industry representatives tour Rauscher Dairy in Huntingburg, Indiana.

PHOTO3: The Koester family built a new freestall barn and installed four Lely robots in 2012.

PHOTO4: The Rexing family welcomes participants to New Generation Dairy in Owensville, Indiana. They enjoy teaching children and adults about modern dairy farming. Photos by Kimmi Devaney.