From this and a dry matter (DM) analysis, we can derive the following: bales per acre, tons per acre, total tons of DM and nutrients removed. Soil characteristics can be assessed in an alfalfa field, while site-specific yield within a field cannot. As a farmer, difference in the potential of some areas of the field can be observed qualitatively but not quantified.

Drones, also called unmanned aerial vehicles (UAVs) or unmanned aerial systems (UAS), are one way in which the variation in yield and quality of alfalfa could be measured. The commercial operations of drones require the remote pilot to obtain a license from the FAA and also register the UAV with the FAA as well.

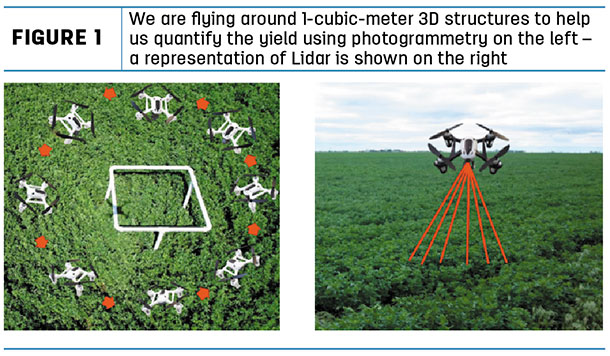

Two main methods exist for us to quantify yield:

- Photogrammetry

- LiDAR (light detection and ranging)

Photogrammetry uses pictures from multiple angles, camera orientation parameters, GPS and unique aspects of each photo to stitch the images together into a 2D image or 3D surface. From the 3D point cloud, the surface area and volume of material can be estimated.

LiDAR uses the light from lasers to determine the distance to an object. The pulsed lasers are emitted from the unit, and the time it takes to return is used to quantify the distance. LiDAR data is used to create digital elevation models, which is of interest to agriculture. When estimating yields, the canopy height models would provide information of everything that is above the ground’s surface. This data is used to create a volume and a surface area to measure.

How much spatial resolution is good enough?

For photogrammetry and LiDAR, precision and accuracy can be limited by a number of factors: GPS quality, analytical variation, flight duration, time, flight altitude, coverage, flight speed and wind speed to name a few. Field efficiency is still important to the operation of a UAV as battery life and other factors will dictate how many acres can be covered within a specified time.

For photogrammetry, overlap of the photographs is essential for proper stitching. For the sides and front overlap, 60% overlap is generally the minimum utilized. As the amount of overlap increases, the duration required for each acre will increase. The flight altitude will also influence the time required for obtaining images. As flight altitude is elevated, each image will represent a larger area. Thus, it would take fewer images to cover a field. This increase in altitude would inherently lead to less processing time but a lower resolution. The current flights for evaluating alfalfa yield were conducted at a flight altitude of 30 feet above ground level. The goal was to create a detailed surface feature for developing regressions.

For the LiDAR system used, distance measurements are collected at a constant rate. Therefore, as speed increases, the point density of the LiDAR system decreases. Point density follows a power series and will be directly proportional to 1/velocity. The current LiDAR system we are testing can measure 320,000 points a second in a static position. As the flying speed increases, these points will be spread over a greater area. Increasing flight speed results in less spatial resolution, but also decreases the computational complexity of the data, resulting in a faster processing time. With the LiDAR system, there are many different ways to measure volume – block method, octree method, alpha shape method and cube method. As the speed increased, the alpha shape method provided the least change in volume measured. Similar to photogrammetry, as altitude increases, the coverage area for the LiDAR scan also increases, but again resolution goes down.

Comparison

LiDAR focuses more on the geometric relationships: distance, angle and reflectance measurements. This data is then transformed from spherical coordinates to Cartesian coordinates (x, y and z) for use. Photogrammetry utilizes spectral data associated with red, green and blue to create one related dataset. Photogrammetry is easier to visually understand and analyze as you can infer from the images what is visually represented.

The histograms from both the LiDAR at a steady state and photogrammetry were similar but offset by 100 millimeters in height. More data will have to be analyzed to determine which would be preferred.

A challenge for both is logging. It is hard to predict how much crop there is when the material is logged, as the actual height is greater than the measured height of a crop. With the ample rainfall last year, harvesting windows were greater than typically expected. Therefore, the apparent height measured in both cases was less than the true height of the plant.

In terms of our return on investment (ROI), both systems are going to need further analysis to determine which system is going to be the most cost-effective. Both require significant post-processing. For each there are different apps or programs, which could be used to analyze the data. Photogrammetry lends itself to currently available drones as most commercially available drones are used to collect images. Photogrammetry provides a more turnkey solution at the present time; however, issues with accuracy are expected. At the present, LiDAR is going to inherently require more investment, as larger drones are required to carry the LiDAR system. Also, the LiDAR system is an additional purchase. The actual ROI will be dependent upon what management decisions can be ascertained from the data obtained. From the yield maps and variable rate equipment, cost saving or improvement in the resource allocation would have to be realized to make the drone a practical purchase.

Future

At the present time, there is no system that gives us a simple push-button solution for determining yield. Some systems will create a map with pretty colors. However, due diligence must be used to ascertain how their data was obtained and validated. Post-processing is still a major obstacle, but this challenge is being addressed by other advances. ![]()

-

Josh Jackson

- UK Extension Specialist

- Biosystems & Agricultural Engineering

- Email Josh Jackson

This presentation was given at the 38th Annual Kentucky Alfalfa and Stored Forages Conference, February 2019.