With software and tools to monitor and track every step your cow takes, and every pound it produces, it gets harder and harder to know which data points to look at and what they mean specifically for milk quality.

Data from an effective farm management system is one more tool in the toolbox to help manage milk quality. Knowing how to use data points on measurables (conductivity, lactate dehydrogenase [LDH], liner slips, unit kickoffs and milk flow), paired with time-honored tools of good cow sense and somatic cell count (SCC), can lead to timely and effective management decisions.

Conductivity

Understanding the factors that affect conductivity and how it is measured make it a valuable tool in a complete udder health program. The electrical conductivity of the milk depends on the amount of free sodium and chloride ions in the milk. Cells in the udder release sodium and chloride ions as a response to inflammation, making conductivity an accurate indicator of inflammation in the udder. While “good” conductivity levels are relative to the individual cow, one should always be concerned with a measurement above 8 millisiemens per centimeter.

High relative conductivity can be an early indication of mastitis, and cows whose levels begin to trend upward should be observed or checked with a cowside somatic cell counter or other mastitis detection tool. Your herd management software can generate an alarm when the relative conductivity threshold of an individual cow is reached.

While decisions based on conductivity can impact milk quality at the individual cow level, this piece of data cannot fix consistently high SCC levels. There are some important limitations to using electrical conductivity to detect mastitis. First, conductivity is influenced by inflammation, so it is most sensitive to organisms which cause rapid and significant inflammation. Second, much like humans respond differently to the common cold, individual cows respond differently to inflammation and have different “normal” levels of conductivity. Keeping these limitations in mind will help get the most value from monitoring conductivity.

LDH

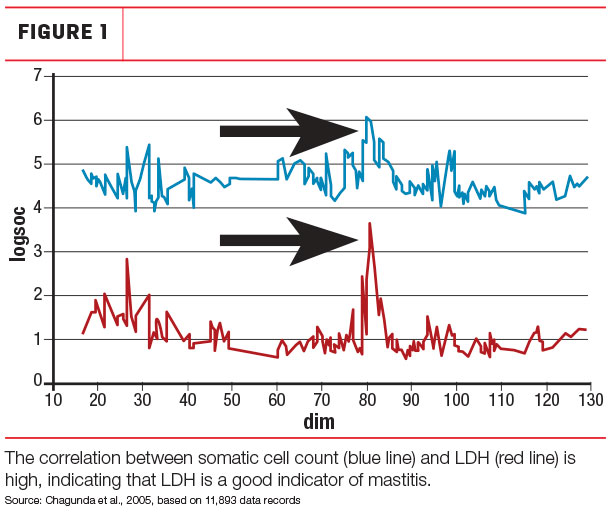

Certain farm management tools can measure the presence of LDH in the milk. LDH is found in large amounts inside the cells of different mammary tissues, but milk levels are generally low. When udder tissue is damaged and cells are destroyed due to a mastitis infection, LDH is released into the milk. Tissue damage in other parts of the body also releases LDH into the bloodstream. However, in most cases it will not affect the LDH level in milk. The exception may occur in cases of systemic infections, when vascular permeability increases in all body tissues, resulting in an elevation of LDH in milk. The graph shows how LDH is correlated to SCC and therefore can be used as an indication of mastitis infection.

If you can catch a cow whose LDH levels are going up, you’ve caught that cow well before it’s developed a significant case of mastitis. Those cows should be cultured and monitored for future intervention and treatment.

While conductivity and LDH measure quality issues with the milk itself, data collected on liner slips and unit kickoffs, as well as milk flow, are indicators of milking performance that may shed some light on the overall bacterial quality of the milk produced.

Milk flow data

Group milk flow data from your farm management software can indicate whether cows are being prepped correctly and if the milking system is operating correctly. The top 3X parlor herds in the U.S. are averaging 11.6 pounds per minute during peak flow, while the lower-performing herds average 7.6 pounds per minute. Peak flow rates are one indication of proper udder prep – the higher the peak flow, typically the better udder prep. A longer milking duration with a higher flow during the latter part of milking can be an indication of inadequate stimulation time or prep-lag time. If cows are not being prepped properly, milkers are not only likely to miss signs of clinical mastitis but also fail to remove bacteria from teat skin and teat ends.

Liner slips and unit kickoffs

When a liner slips or a cow kicks off the milking unit, bacteria from the environment can enter the milking system. The more times this occurs, the higher the risk of impacting bacteria counts or new mastitis infections. There are many factors that can influence the number of liner slips and unit kickoffs, including but not limited to inappropriate teat-end vacuum level for the liner chosen, inappropriately matched liners to teat size, extending liner usage beyond manufacturer’s recommendations, teats not dried completely prior to unit attachment, poor unit alignment and take-off settings.

It is difficult to provide an industry-wide benchmark for these numbers due to the level of variation between farms. However, each individual farm can benchmark their own performance against farm outcomes and changes made in the parlor (such as a liner switch). Monitoring these parameters over time while looking for trends or anomalies will provide the most value.

Robotic dairies can have an advantage over parlors, as there are indicators beyond what can be physically observed. In a parlor, only conductivity, milk flow, slips and kickoffs can be measured, whereas robotic operations have the additional benefit of measuring LDH. When it comes to milk quality, whether in a parlor or robotic system, all indicators should be verified with cultures, milk quality measurements and the standard operating procedure the farm has in place. The data helps identify problem cows or situations you may otherwise not have known about, but it’s most effective when it’s worked into a system that includes time-honored tools. ![]()

Kristy Campbell is a DeLaval milk quality and milking performance advisory team manager.

References omitted but are available upon request. Click here to email an editor.

-

John Gerbitz

- Dairy Advisory Specialist

- DeLaval