On-farm liquid manure storages serve as a vital infrastructure for small- to large-scale dairy producers. Having on-farm storage allows for manure to be applied at proper times of the year when climate conditions are appropriate, allows for nutrient management planning and decreases the risk of impacts to water quality.

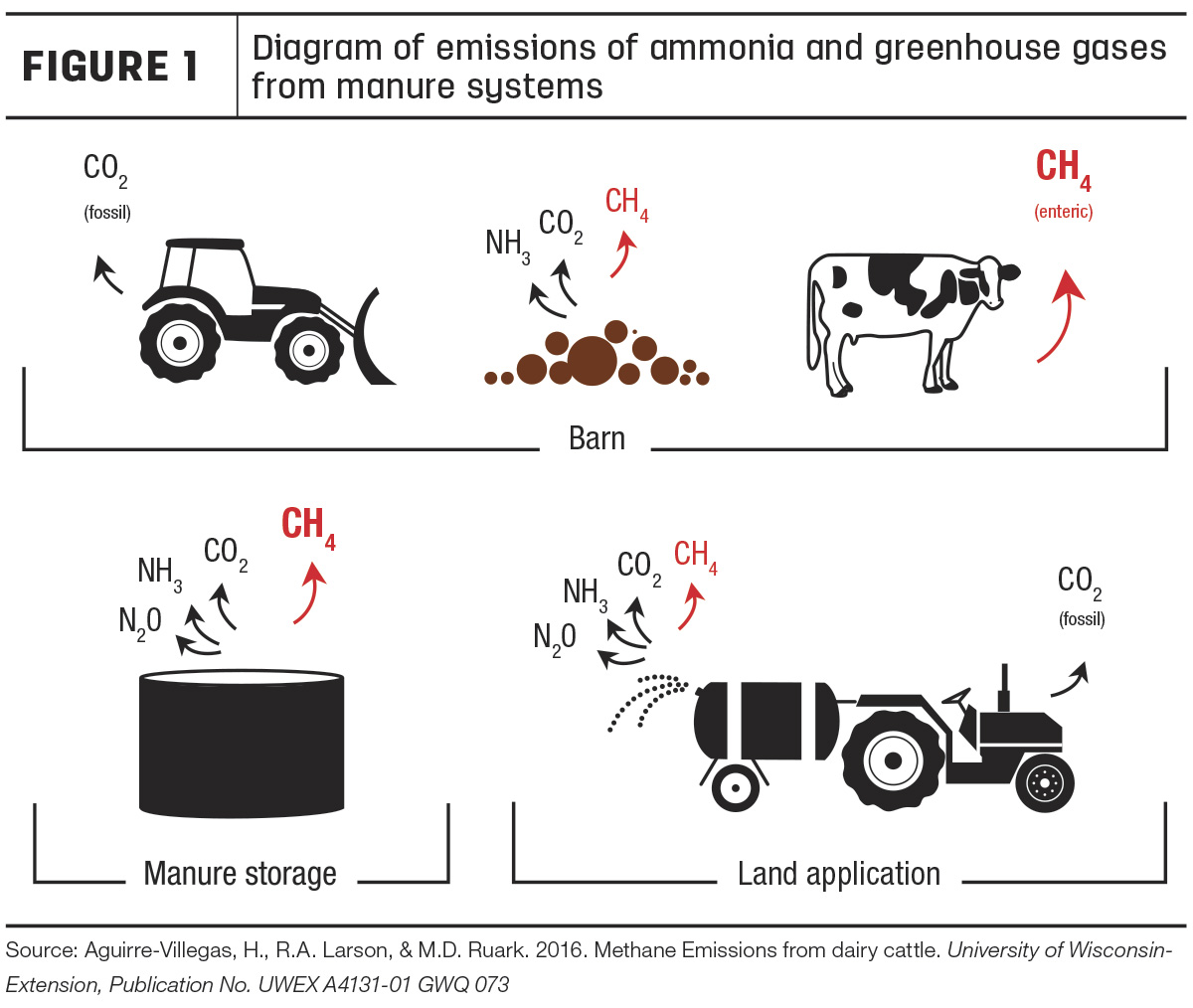

While liquid manure storage reduces concerns related to manure and water quality, storage will negatively contribute to air quality. When liquid manure is stored, ammonia, methane and nitrous oxide gases are emitted into the atmosphere (Figure 1).

Methane and nitrous oxide are both considered greenhouse gases (GHGs) and have a significantly higher global warming potential than carbon dioxide. Both are emitted from manure storages and represent roughly 70% of GHG emissions lost from manure on dairy farms. When ammonia is lost from manure storages, not only does it reduce the concentration of plant-available nitrogen within the manure, reducing the fertilizer value, but it is also an environmental and human health concern.

When emitted into the atmosphere, it can transform into nitrous oxide (a GHG) or particulate matter. Agriculture is the leading contributor of ammonia to the atmosphere in the U.S., according to the EPA, and losses from manure storage are a large source.

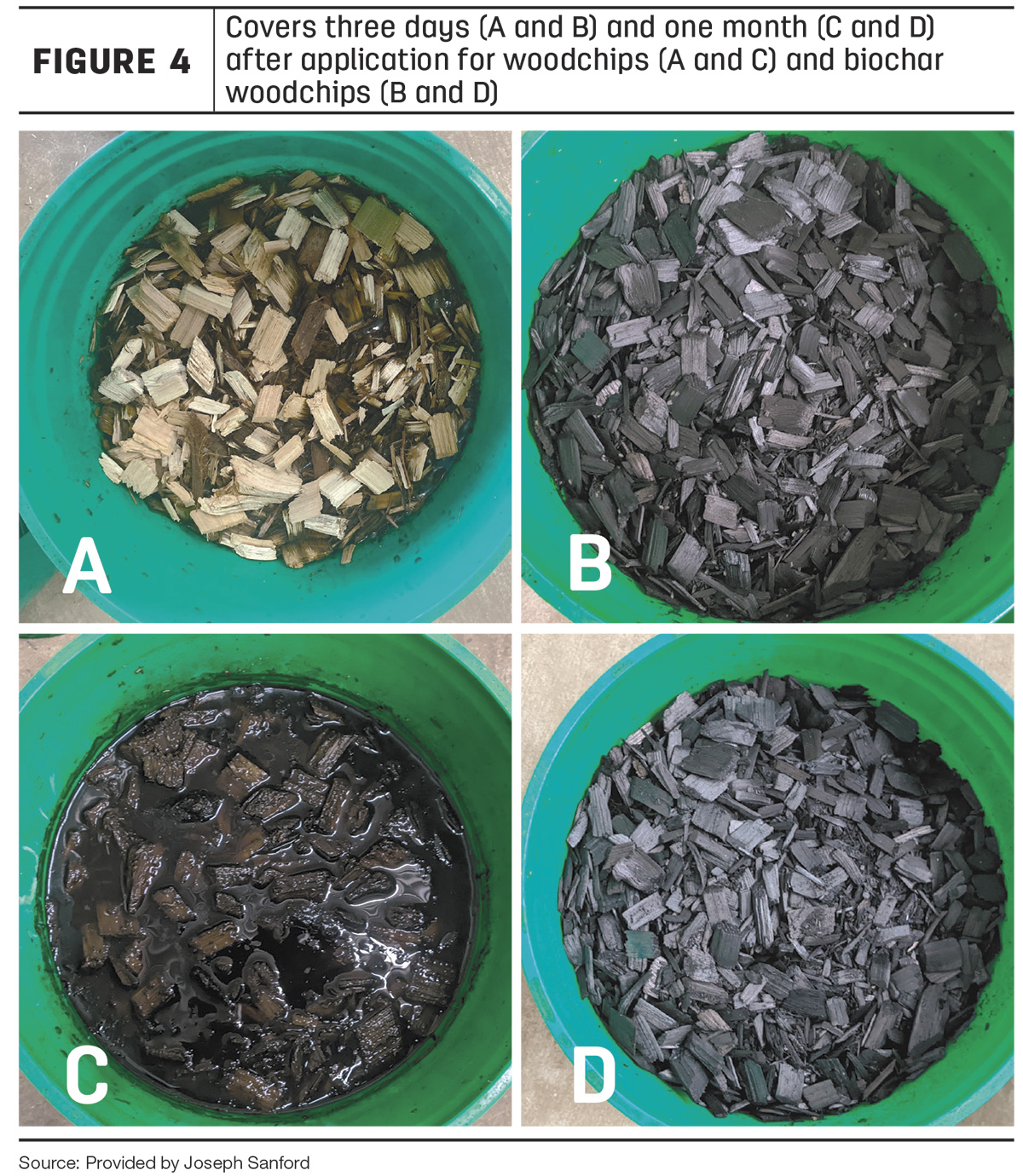

Biomass permeable covers (adding straw or woodchips over the surface of the storage) are a technique used to mitigate emission issues. These methods are fairly effective for reducing ammonia emissions. However, biomass covers are often limited due to high biodegradability and require frequent reapplication. Due to this, biomass covers are often overlooked as an option for addressing ammonia losses due to poor long-term performance and maintenance. Converting biomasses to biochar and applying it as a cover has the potential to address this issue.

Why may biochar be a suitable cover compared to biomass?

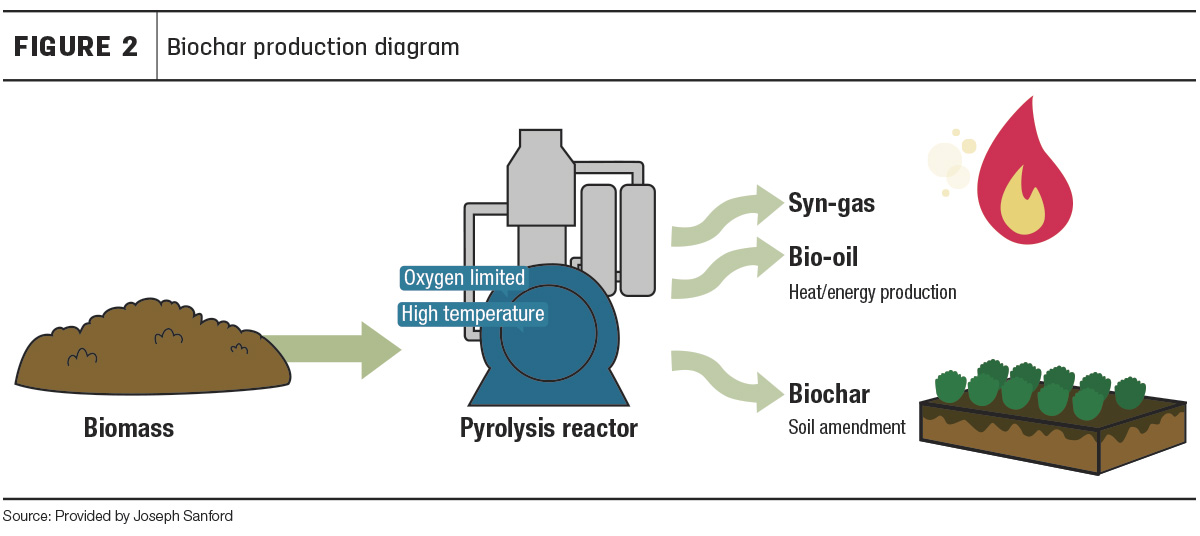

Biochar is a carbon-rich product resulting from a process called pyrolysis, where biomass, such as wood or agricultural residues, is thermally treated at high temperatures under oxygen-limiting conditions (Figure 2). This process results in syngas and bio-oil, fuels that can be used for heating or energy production, and a solid product known as biochar.

Biochar has unique characteristics, such as high carbon content, low density (5 to 20 pounds per cubic foot), is highly porous, hydrophobic, and can bind with nutrients and minerals, including ammonium. These characteristics vary depending upon what the biochar was produced from (the feedstock), the temperature it was produced at (somewhere between 660°F to 1,650°F) and the time it was in the reactor.

Adding biochar to agricultural land has long been suggested as a soil amendment that can be used to sequester carbon, improve soil fertility and reduce nitrate leaching, among other crop production and environmental benefits. These studies have resulted in a lot of interest in using biochar in agriculture, and recent interest in carbon markets has accelerated these discussions. While applying biochar directly to cropland could help in achieving carbon sequestration goals, there are other opportunities for biochar to be incorporated into livestock production systems, particularly around manure management. Given biochar's properties, using it as a floating cover to reduce ammonia emissions might be a way to incorporate biochar into agriculture soils to sequester carbon and help in reducing storage emission concerns.

Ongoing biochar cover research

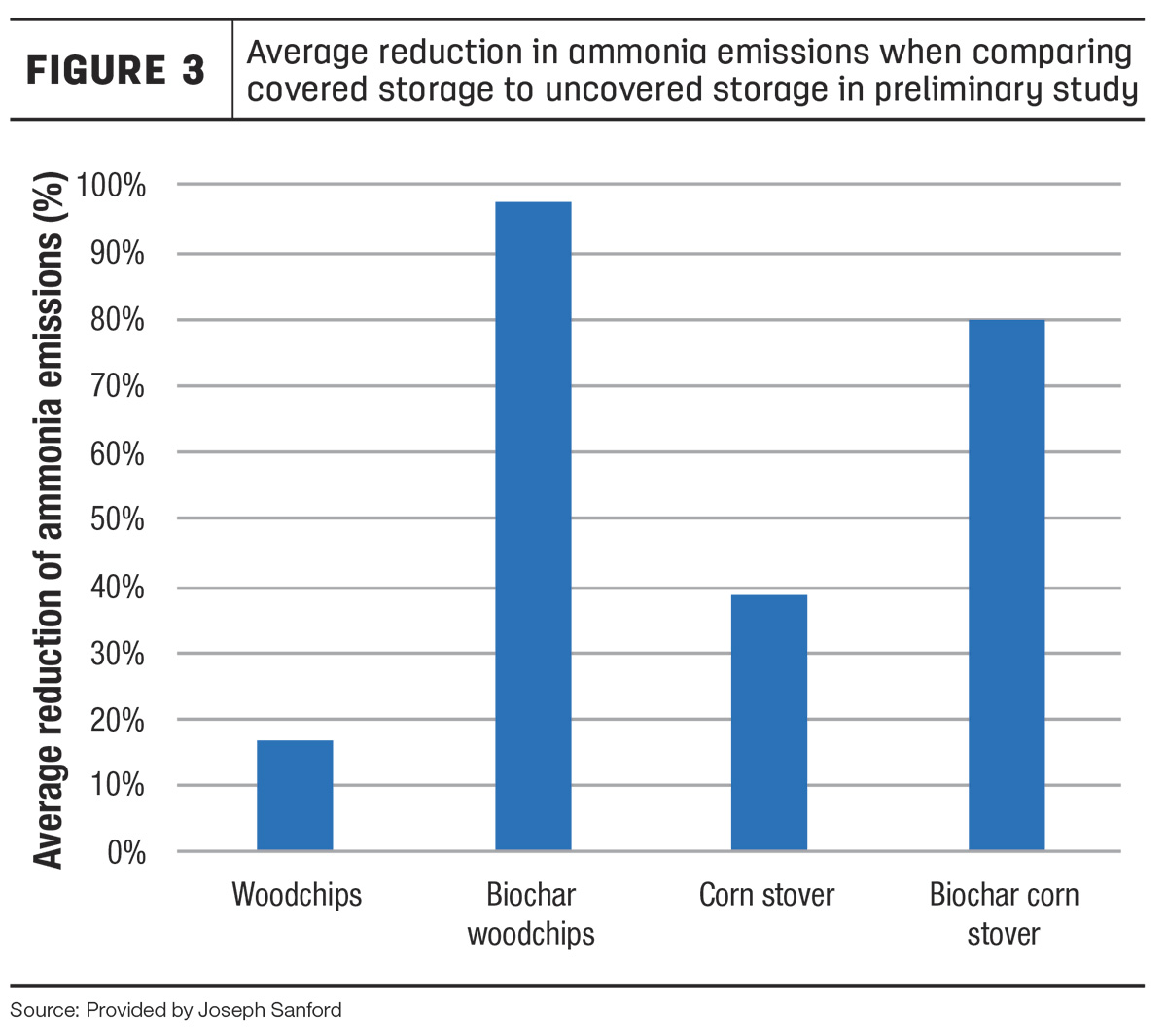

The University of Wisconsin – Platteville Agriculture Waste Management Lab has been conducting small pilot studies that explore using biochar as a manure storage cover. In this work, unprocessed biomass and biomass converted to biochar were applied to a 2-inch depth over the surface of the manure. Preliminary results have found that biochar is much more effective at reducing ammonia emissions during storage than unprocessed biomass when tested over the course of five months (Figure 3). This is likely due to the stability of the cover, as the biochar remained floating on the manure surface throughout the experimental period, while unprocessed biomass began sinking and degrading within one month (Figure 4). While the covers did reduce ammonia, results for methane and nitrous oxide emissions were variable, with some biochars reducing emissions (such as corn stover and manure solids) and some increasing emissions (woodchips). More studies are planned to identify what biomass and production temperature will optimize reductions in ammonia and GHGs.

Challenges to biochar manure storage covers

While biochar manure storage covers show promise, more research is needed to optimize what type of biochar is best suited for a cover to mitigate both ammonia and GHGs. Feasibility and accessibility to biochar are other questions that need to be evaluated. While there is a lot of interest in biochar production as a carbon sequestration technique, the infrastructure for production is still in its early stages.

In addition, producers interested in using biochar as a cover will need to keep in mind additional management considerations. For instance, manure storage design and capacity may be impacted. The preliminary study mentioned found that biochar covers also reduced evaporation from the manure surface; thus biochar covers may reduce a storage's design capacity volume due to reduced evaporation. Additionally, producers will need to consider how biochar will be applied over the surface of the manure storage and any potential implications for pumping manure.

John Rodwell is an undergraduate research assistant for the School of Agriculture at the University of Wisconsin – Platteville.