New Holland reveals T9 SmartTrax with PLM Intelligence for model year 2025

For the most demanding tasks out in the field, having the right system – wheel unit or track – is make or break. With the launch of the T9 SmartTrax with PLM Intelligence from New Holland for model year 2025 comes a track system built to deliver unmatched performance – regardless of the field conditions.

Mastering the terrain with T9 SmartTrax

The T9 SmartTrax with PLM Intelligence showcases a suite of best-in-class features designed to elevate performance and simplify routine maintenance.

The inclusion of advanced oscillating roller wheels and vibration dampening mount suspension in the track system contributes to elevated ride quality and prevents uneven wear during field-to-field transportation. To ensure ease of daily maintenance, clear track system hubcaps have been integrated, providing straightforward access to critical components. The new track system for the T9 tractor also streamlines maintenance and optimizes tension by eliminating manual adjustments with its automatic track tensioning system – this update can contribute to lengthening the lifespan of the track belt.

Available for agricultural use on five model-year-2025 T9 models – T9.520, T9.580, T9.615, T9.655 and T9.700 – that range from 475 to 645 rated horsepower, the SmartTrax system ensures performance in a variety of terrains while enhancing overall operational performance and preserving the integrity of the field environment.

Photo courtesy of AcreShield.

Yield Optimizer helps farmers choose the best hybrids for their farms

Yield Optimizer, the first independent seed selector program that arms farmers with objective seed performance data and helps them choose the best hybrids, has been released by AcreShield. This new tool is backed by an industry-first yield performance protection warranty program.

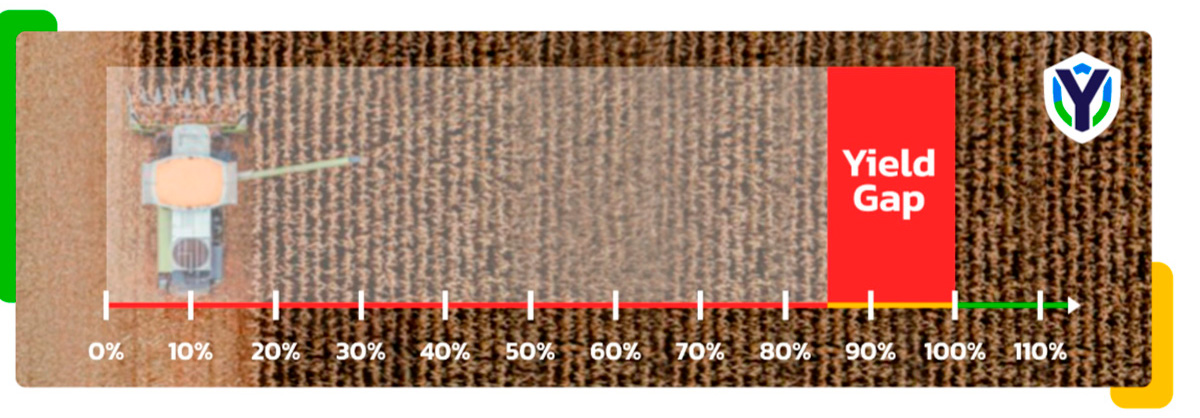

Maximizing yield through minimizing components of yield risk is key to determining profitable farm operations. Profitability generally depends on getting crop yields close to 100% or more compared to historical yields. While crop insurance covers up to 85% of a farmer’s historical yield, profits are at risk when yields fall between 85% and 100%. This 15% shortfall is the yield gap. Before Yield Optimizer, there was no cost-effective seed selection program with financial protection to safeguard farmers whose yields fell in the yield gap.

Yield Optimizer, with the associated Yield Gap protections, is available in a three-tiered offering with introductory pricing at $5, $8 or $15 per acre. The respective yield gap protection payments for these prices are up to $25, $56 or $105 per acre. Farmers can sign up during the early sign-up period with introductory pricing valid until April 15. Sign-up will continue at standard prices after this date. AM Best A+ rated reinsurers cover eligible protection warranty payments.

Photo courtesy of Nelson Irrigation.

Nelson Irrigation Corporation is pleased to introduce the new R33-NV and R33LP-NV Rotator sprinklers

A direct replacement for 3/4-inch brass impacts – Nelson Irrigation is pleased to introduce the new R33-NV and R33LP-NV Rotators. The R33-NV uses Nelson’s proven Rotator technology to provide longer throw distance, fight the wind and deliver uniform coverage. While brass sprinklers are prone to damage, clogging and theft, the R33-NV is easy to clean, easy to repair and costs less. The R33LP-NV is a low-pressure version of the R33-NV. The pressure range of the R33-NV is 40-65 psi (2.75-4.5 bar), while the R33LP-NV is 25-50 psi (1.75-3.5 bar). The R33-NV Road Guard easily snaps on to convert the sprinkler to part-circle operation, offering the best edge-of-field solution to prevent watering on adjacent roads and fields.

The 3NV nozzle, first introduced in 2015 in the 3030 series pivot sprinklers, is now incorporated in the 33 series Rotator. This innovative dial nozzle combines multiple functions – nozzle flush, line flush, shutoff – all without removing the nozzle.

System types include: portable aluminum, polyethylene and PVC pipe for wheel lines and permanent solid set systems. Applications include:

- Irrigation of all types of crops including forage crops, vegetables, grain and pastures

- Overhead irrigation, cooling and environmental control for nursery crops, tree, vine, small fruit and berries

- Also suitable for revegetation, mining and other specialty uses

Photo courtesy of Horning.

Horning’s new entry-level roller mill just right for smaller operations

Turning grains into feed is now easier than ever for hobby farmers and homesteaders, thanks to the new Horning RM1808e roller mill. This compact but rugged mill packs professional-grade milling power into a user-friendly package. It’s designed for anyone ready to take the first step in producing their own feed.

Many people are concerned by the prevalence of bioengineered crops and crops grown with chemicals. Horning Manufacturing, an established producer of agricultural equipment, recognizes that one of the best ways for livestock and poultry owners to control what their animals eat is to process their feed from crops they have grown themselves.

"With the 1808e, we've created an 'entry-level' roller mill that's built very similar to our larger models," said Leon Horning. "It's perfect for folks who want to grind their own grains into livestock feed but don't need an industrial-scale mill."

The mill is compact, measuring about 2-by-3 feet and standing less than 4 feet tall. Despite its size, the 1808e can grind up to 70 pounds of dry corn a minute. This is due to its powerful motor and hardened steel rolls that come in a range of groove configurations. The rolls are easily adjustable for finer or coarser grinds. Key features include spring-loaded rolls to handle debris, a simple belt drive and a magnetic switch for safety.

"The 110-volt motor makes this mill so easy – just plug it in, pour your grains in the hopper and watch the freshly milled feed come out the other end," Horning says. "Your livestock and poultry get the great taste and nutrition of feed made from your own grains. Plus, [you get] the satisfaction of being more self-sufficient on your farm."

Horning makes two other stationary mills, both with higher capacities. But they see the 1808e as perfect for off-grid living or for anyone who wants the cost savings and animal health benefits that come from making their own feed.