The buzzwords in the industry right now are animal welfare, lameness and cow comfort. The general public and food retail giants such as Walmart and Tim Horton’s that purchase our dairy products want more than just a quality, well-priced glass of milk; they want assurance the animals producing this product are well cared for.

I’ve been in the hoof care business for more than 22 years and the dairy industry all my life, and I believe farms think they are doing all they can to provide the environments for optimal animal welfare and comfort; however, the reality is: Our industry lameness average is still too high – estimated at 25 to 40 percent, depending on which study you want to quote.

Many believe that 0 percent lameness is not a possible or a realistic goal, but I am challenging every dairy to have more days with no lame cows than days with a cow with lameness issues.

This is possible and must be the goal if we are to improve the industry and satisfy our customers’ wishes. We all know a healthy cow is more productive and profitable than a lame one, so this goal is a win-win for everybody, especially the cow.

So how do we achieve zero lameness when we all know lameness is a multi-factorial problem? When I’m working with a client or talking about lameness, I always preach, “Control what you can control.”

By doing this, we can hopefully help the cow ride through instances out of our control that will hinder optimal hoof health. For example, we cannot control a heat wave, but we can make sure the cow is wearing a well-fitted pair of running shoes to handle the added stress.

Hence, this is my three-step program to zero lameness:

- A properly timed, functional hoof trim

- Well-managed infectious lesion program

- Stress-free stockmanship

1 Timed, functional hoof trim

The majority of my clients are on a regularly scheduled trim appointment ranging from weekly to bimonthly to monthly. The problem is how each client uses this trim day and if they are maximizing the return on investment of my invoice or just creating another “expense” off their milk check.

Some dairies use the day for what I call preventative maintenance trim (PMT) days, while for others it’s a day for me to work on lame cows and trim long toes (Figure 1 – Incidence of lesions for a dairy using PMT vs. a dairy not using PMT).

Unfortunately, more clients treat trim day as an expense rather than an investment. When my herds were smaller and whole-herd trims were the norm, it was easy to make sure each cow came through the chute every five to six months; however, that did not guarantee the cow would be trimmed at her optimal stage of lactation or service those that needed it more than twice during their lactation.

This was the main reason I invested in computer programs such as Hoof Supervisor (HSS) and DairyComp 305 to manage and record trim dates for my clients.

I now make the PMT for some of my clients or set it up in their record-keeping software. We need to record lameness events just as we record mastitis, dry-off, vaccinations and other health events on the cow card. I create my PMT list by scheduling a trim command in DairyComp 305 for:

- Dry-off trim: Days carrying calf (DCC) = greater than 189 days

- Pre-peak production trim: Days in milk = 80 – XX* days

*XX depends on if the client is on a monthly or biweekly trim schedule, e.g., for a monthly herd, days in milk = 80 to 108 (four weeks = 28 days)

- Safety catch trim: Days since last trim more than 120 to 170 days depending on wear or lack of wear from flooring surface. The last criteria is a “safety catch” for cows that take longer to get pregnant and have more days between their pre-peak production trim and dry-off trim.

- Re-checks: Any treated lame cows from previous trims for inspection or block removal, or a high-maintenance cow that requires more frequent claw inspection than the set PMT for the herd. This list is created in Hoof Supervisor.

Clients that have adopted the PMT program have seen lameness incidence improve, in some cases declining dramatically from as much as 50 percent lameness down to just 5 to 8 percent.

There are many lameness factors out of our control, but by following a set PMT for your herd, you can help the majority of your cows ride through heat stress, ration changes or other uncontrollable short-term factors without having a lameness incidence.

2. Infectious lesion program

When we talk infectious lesions, the talk quickly goes to the number one cause of the majority of lameness in the industry – digital dermatitis (DD). There is room for improvement in controlling these lesions on dairies. DD is a hygiene problem, described as “mastitis of the foot”; we need to start managing, treating and preventing DD in ways similar to how we handle mastitis.

If a cow had mastitis, would you just dip her teats more? No. Apply the same concept for footbaths and DD. We cannot just footbath more when we are in a major outbreak of ulcerated M2 DD lesions.

Nor can we get away with only dipping two or three teats with impartial coverage and expect a good preventative barrier against mastitis-causing bacteria. The same goes for the footbath. If it is too short, the cow may dunk only a couple of hooves at best – or she may side-step the bath altogether.

I’ve started talking foot dipping instead of footbaths to help emphasize the importance of a proper preventative footbath program. Running a footbath is expensive and labor-intensive, so each day a footbath is offered needs to be maximized. In order for a farm’s footbath program to have financial and cow welfare returns, the baths need to be 10 to 12 feet long, with 10- to 12-inch curbs and sides to prevent side-stepping.

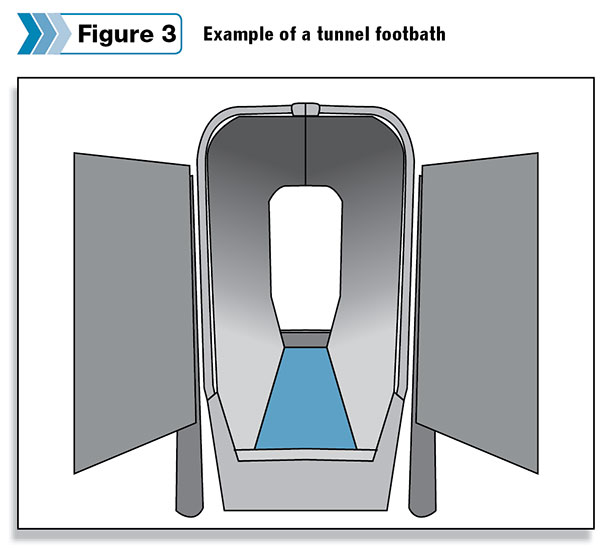

Clients that have gone to the tunnel concept or higher sidewalls have seen better cow flow and cleaner baths, sometimes resulting in being able to run more cows per bath (Figure 2 – Proper footbath design from University of Wisconsin – Madison; Figure 3 – A tunnel footbath may increase cow flow and keep the bath cleaner, allowing for better efficiency).

The biggest misconception is that the “product” is the deciding factor in a footbath program. The majority of footbath products have little or no trials with control groups to really determine long-term effects on the organism that causes DD.

This is why I recommend copper sulphate as the go-to in a good preventative footbath program. Another misconception is that footbaths only need to run in the milking herd. If your lactating herd has DD and there is no dry cow or pre-lactating heifer preventative footbath program, you will always be taking two steps forward and three steps back.

The problem is not the product, but the program, just like you need a good dry cow mastitis prevention program.

Also, it takes more than a footbath to get DD under control. Just like we forestrip and monitor high-somatic cell count cows to find early cases of mastitis, we need to be more aggressive in DD pre-screening.

This includes pen or parlor walks and identifying chronic DD cows. If we find the ulcerated DD lesion early and topically treat, we will lower the number of chronic cows, thus reducing further incidence. There is a great app available through Zinpro that is a great way to easily score and track how DD is being controlled in your herd.

3. Stress-free stockmanship

The final step to moving closer to zero lameness is finally starting to get some notice in the industry: stress-free cattle handling. As an industry, we tend to move cows at a much faster pace than is natural for a cow. Add a slippery surface to that, and it’s a trauma injury waiting to happen. A rule of thumb is: A cow’s natural walking speed is about half of our walking speed.

Also, a cow normally walks with her head down, looking where she’s walking; if her head is up, then we are likely pushing her at a speed that is too fast.

Employee training in cattle behavior and handling is crucial to prevent lameness from sole fractures and white-line lesions. Figure 4 shows pressure zones, blind spots and handler position for movement direction.

Whistling, yelling and making noise is just being counterproductive when trying to move cows in a calm, controlled manner and desired direction.

Stress-free stockmanship is a skill that needs to be learned and consistently applied by all employees interacting with animals. It is important right from when we first start handling calves all the way to the lactating herd.

In conclusion, our industry is under pressure to provide improved cow comfort and welfare, but I believe lameness can be reduced to well below 5 to 10 percent by practicing these three steps. It’s all about controlling what you can control to ride through the times when factors affecting lameness are out of your control.

All of this is not possible without monitoring good records and a complete team effort between employees, trimmer, vet and nutritionist. If we are not striving toward zero lameness, it is too easy for the abnormal to become normal and a lame cow to look like a normal cow.