For every dairy producer, the primary objective of good reproductive management is to assure cows calve at optimal intervals and maintain milk production at peak levels of efficiency. However, this requires producers to constantly keep a close eye on their cows, which isn’t always an easy task.

Automated heat detection systems are making this possible in today’s industry. However, most systems on the market, including AfiAct, are able to provide the producer with more that just a heat detection tool.

“Our activity monitoring system has been on the market for more than 25 years,” Noa Yonish, marketing communication manager at Afimilk, says. “It was the first commercial system to use a pedometer for estrus detection.”

Yonish explains that the company, S.A.E. Afikim , more commonly know as afimilk, started in Israel in 1977. The goal of the company was to develop, manufacture and market computerized automation and herd management solutions for the modern dairy farm – a goal they continue to pursue today.

Yonish explains that the initial goal for their activity monitoring system was to collect data automatically and use that data to improve farm operations. “The strong correlation between herd fertility and farm profitability made heat detection one of the first and most important goals for this product,” Yonish says.

AfiAct

AfiAct is an automated heat detection system that is part of a comprehensive herd management system (afimilk), but can also be used as a stand-alone system for heat detection and fertility management.

Using automated heat detection systems, such as AfiAct, replaces traditional heat detection methods such as visual observation or tail chalking, Yonish says.

“First and foremost, timed breeding and high fertility rates demand accurate cow heat detection,” Yonish says. “AfiAct, as an automated heat detection system, is beneficial for any dairy that wishes to improve herd fertility, save on labor and minimize the use of hormones.”

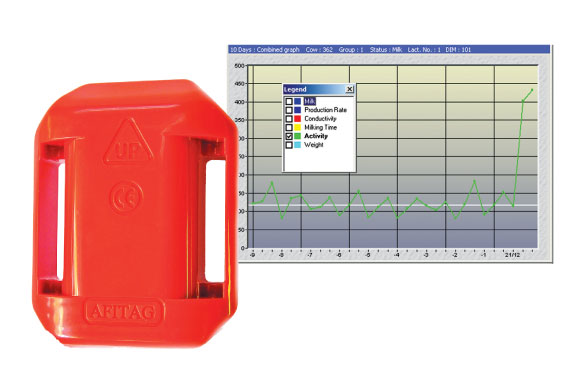

The AfiAct system detects heat in cows by measuring the activity of the cow. The system is based on the data collected from pedometers attached to the cow’s leg.

The AfiAct system has three main components – the software program, radio frequency antennas and pedometers. The antennas can be installed at the entrance of the milking parlor, reading activity data of the cows’ pedometers as the animals enter the parlor.

The data collected is then sent to the software program on the computer, where it is analyzed and compiled into lists producers can use.

In a heifer-raising system, the antennas collect the data from the tags in the heifer pens. In this situation, Alon Arazi, applied research manager at afimilk, explains that the antennas are placed near water troughs or passages between the feeding and drinking areas, where animals will walk by every day.

Readers can also be used as an alternative to antennas, but it all depends on the needs of the farm, Arazi says.

Pedometer options

Yonish explains that AfiTag was the first commercial pedometer marketed worldwide and it has two main purposes – cow identification and activity measuring. This pedometer incorporates a device that counts the cow’s steps and sends this data to the heat detection module on a PC, where it is then analyzed to determine cows in heat.

These tags can also be transferred between cows on the farm, making them flexible and cost-effective devices for heat detection. The AfiTag, however, is not the only pedometer available for use with this system.

“The Pedometer Plus tag is an extended version of the other AfiTag pedometers,” Arazi says.

The Plus tag measures more of the cow’s activity than just her steps. It also measures additional rest behavior including the number and duration of lying bouts. Arazi says the additional data this tag collects allows for an accurate evaluation of cow comfort and welfare.

The Plus tag provides timely detection of changes in individual and group behavior and notifies the producer of potential health or environmental issues. If an immediate intervention takes place, serious health issues are avoided, costs are reduced and herd health and comfort levels are maintained.

“Improving cow welfare paves the way for dairies to achieve higher milk production and better milk quality,” Yonish says. “The days of treatment for sick cows are lowered and the labor generally required for monitoring, prevention and treatment is also reduced.”

Measurements

Yonish explains the system is able to provide a wide range of statistical analysis and reproduction performance information.

These capabilities enable monitoring of the reproduction program and comparing the current status of the program with previous periods and trends.

The measurements and results generated in the software program encompass common reproductive parameters such as pregnancy rate, conception rate, heat detection rate, open days, cycle distribution, average days in milk and calving intervals, among others.

The data can then be analyzed and broken down to cover a specific group of animals or sub-populations within the herd. The rest behavior data, analyzed by group and herd, can indicate inadequate and unfavorable conditions that may be contributing to a reduction in estrus behavior, Arazi says.

Yonish explains that her team’s approach in creating the system was to keep it simple. “The dairy producer needs no more than a few minutes each day to identify those animals eligible for breeding,” she says.

The system also has the ability to give alerts for cows that fail to show signs of heat, which could mean anestrous cows or cows that should be checked.

Other alerts include cows that have possibly aborted, as they will resume heat cycles after being confirmed pregnant. A list of possible lame or sick cows can also be generated from the system due to a decrease in activity.

Variety of applications

“The main benefit of this system is that it can enhance the dairy producer’s decision-making capabilities and the farm’s profitability,” Yonish says.

Arazi explains that this system can be implemented in a variety of situations, including grazing operations, heifer-raising facilities and milking cow groups, because a unique algorithm is able to collect data accurately for each of these situations.

“Some farms use this system for heat detection in virgin-heifer groups in addition to using the system on milking cows, which provides a full coverage of heat detection on the farm,” Yonish says.

In a grazing operation, Arazi explains that the herds walk longer distances and are usually subject to frequent grazing pattern changes, like grazing during the day and being confined to pens at night.

“This system is able to neutralize these grazing pattern variations, which results in high heat detection rates even in these herds,” he says.

Arazi points out that people should not view this system as just a method of detecting heat in cows. He explains that it can also be used in combination with a sync program if that is what the producer wants to do on his operation.

Establishing a presence in the U.S.

In July, the company decided to establish a presence in the U.S. by opening up a branch, which is based in Massillon, Ohio. Afimilk USA was created in order for the company to be able to provide close support to its customers in North America. This branch currently employs eight individuals that handle logistics, software and technical support as well as sales.

According to Joe Bleau, director of the afimilk’s North American business unit, acceptance of activity monitoring systems by dairy producers in the U.S. has been a slow process if compared to other countries across the globe.

“The U.S. market for these heat detection systems has been slow to mature and slow to accept them,” Bleau says. “However, I think activity monitoring is going to have a big increase and a big impact on the market in the future.”

Currently there are 700 dairies in North America equipped with the complete afimilk system and approximately 85 percent of those operations have the AfiAct heat detection system installed.

Yonish and Arazi believe the main challenge for this company and for activity monitoring systems in the U.S. lies in changing the producer’s state of mind.

“We see there is change in that attitude because people are looking for heat detection solutions with and without sync programs,” Arazi says. “We feel now is the time for these systems.” PD

PHOTO 1: The AfiAct system is a pedometer-based activity monitoring system that detects heat in cows.

PHOTO 2: The strong correlation between herd fertility and farm profitability made heat detection one of the first and most important goals for this product.

PHOTO 3: This system's software program can track common reproductive parameters including pregnancy rate, conception rate and heat detection rate. Photos courtesy of afimilk.

Dario Martinez

Assistant Editor

dario@progressivedairy.com