Editor’s note: The following article is the first of a two-part series regarding hydraulic tube fittings. This article will discuss 37º flare fittings. The second article will discuss O-ring face seal fittings and flareless bite-type fittings. From milking/feeding machines to tractors, skid loaders, tillers, bale choppers and even manure digesters, hydraulic tube fittings are an essential yet often overlooked component of proper dairy and forage equipment maintenance. Fluid leakage is a problem that virtually every farmer has experienced.

Beyond the obvious risks of contamination and inefficient machine operation, one sure consequence is that leakage will cost money. One drop every second for one year can add up to more than 180 gallons – or approximately $3,300! The appropriate techniques to specify and maintain fittings for reliable equipment operation can be understood as “dry technology.”

There are several types of hydraulic tube fittings for industrial applications. The three most common are 37° flare, O-ring face seal and flareless bite-type. Improper installation – the leading cause of fluid leakage – can be avoided by following proper installation techniques for these typical connection types.

37° flare

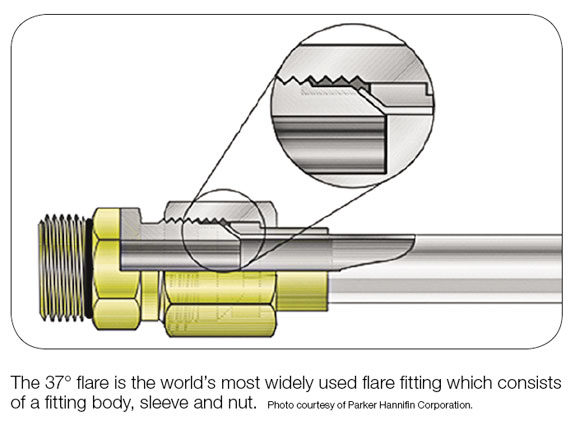

The 37° flare is the world’s most widely used flare fitting. It consists of a fitting body, sleeve and nut. The tube end is flared at a 37° angle and held captive between the fitting nose and sleeve with a tube nut.

When tightened, a metal-to-metal seal forms between the fitting nose and tube end. Proper tightening is critical for withstanding vibration that can cause metal-to-metal connections to loosen during machine operation, particularly on mobile equipment.

37° flare installation

Insufficient tightening and overtightening are frequently to blame for improper installation of 37° flare fittings. The most frequent occurrence, assembly over-torque, collapses the cone on the male end of the 37° flare fitting, causing premature failure that can result in leakage.

As a metal-to-metal seal, these fittings are also subject to scratches – a potential leak path – on the sealing surface (male cone or female flare). Scratches tend to occur from poor tube cleaning, rough handling or the use of poorly welded tubing and redrawn tubing (as opposed to seamless tubing – the recommended tubing style due to higher sealing quality and consistency). If the fitting comes with protective plastic end caps, leave them on until the connection is ready to be assembled.

Parker’s recommended assembly technique for 37° flare fittings is called Flats from Wrench Resistance (FFWR) or the “flats” method. A “flat” is one side of the hexagonal tube nut and equates to 1/6 of a turn. Table 1 shows how many flats to turn the nut past the point of initial wrench resistance. PD

The 37° flare is the world’s most widely used flare fitting which consists of a fitting body, sleeve and nut. Photo courtesy of Parker Hannifin Corporation.

Flats from wrench resistance (FFWR) values for Parker Triple-Lok 37º flare fittings.

DOUG STRICKER dstricker@parker.com