What is the advantage to priming a centrifugal pump? Energy efficiency. Over the lifetime of a pump, this can equal very significant savings. A common misconception is that pumps lift liquid when they are primed and must work harder to do so, but centrifugal pumps do not lift liquid. Priming a pump utilizes the power of atmospheric pressure to do the work of a feeder pump for free.

Atmospheric pressure can provide the intake pressure a pump needs within a certain operating range. The first thing to identify is how much intake pressure the pump needs. This figure is properly known as NPSHr or net positive suction head required.NPSHr is commonly a small number equaling a couple of pounds of pressure. Of course, it is different for every make and model of centrifugal pump and changes at each flow rate. You’ll need the pump performance curve from the manufacturer to properly plan to prime a pump, especially in changing conditions, such as emptying a manure lagoon.

Key #1: Know your pump’s intake requirements (NPSHr)

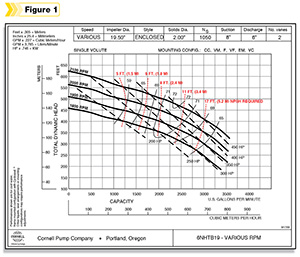

NPSHr is found on a pump performance curve, as seen in Figure 1. Remember, pump curves are based on clear water and feet can be converted to PSI by dividing by 2.31.

Click here or the image to the right to view it at full size in a new window.

Key #2: Understand atmospheric pressure

Atmospheric pressure is a natural pressure we always operate under. How can we use this free pressure?

The storage unit we are pumping from must be an open body of liquid under the full influence of atmospheric pressure.

The pump’s intake plumbing must be rigid and airtight. A primer system simply removes the air trapped in the intake plumbing.

Then, atmospheric pressure pressing down on the top of the body of liquid will force liquid up the intake plumbing of the pump into the low-pressure area at the face of the impeller.

Atmospheric pressure is limited. We can maximize its free energy by placing our pump within range to utilize it, and by utilizing large diameter intake plumbing to reduce friction loss.

Key #3: Plan to prime the pump

Identify the maximum distance that this pump can operate within under prime. This is known as static suction lift and is a measurement from the center of the impeller to the top of the water. Here’s how:

Simplified equation:

Atmospheric Pressure – losses in intake plumbing – NPSHr = Static Suction Lift

Atmospheric pressure under elevations of 2,000 feet is between 30 to 34 feet of head.

For most situations in that elevation range, we can round to 30 feet of atmospheric pressure. This takes into consideration that manure is not water, our liquid temperatures vary, and a little pressure is also needed to keep liquid from turning to vapor.

Example (Figure 1) at 2,000 gallons per minute with 25 feet of 10-inch intake hose:

30 feet – 8 feet – 0.5 feet = 21.5 feet of static suction lift.

Remember thicker, heavier slurries will make the static suction lift less.

Click here for more information on friction loss to find the losses in intake piping and use C – 140.

Key #4: Identify options when limited

Perhaps the lagoon is too deep to keep prime and complete the pump-out. Then, choose a feeder pump with a higher flow capacity than the primary pump, as to not limit your flow rates.

Identify the energy efficiency of feeder pumps available to make the best choice. On large scales especially, utilizing a prime system until it is exhausted will save significant fuel or energy costs.

Look for a primary pump with a low NPSHr and the performance you need when replacing primary pumps, or think about having the primary pump set up as a floating unit. PD