The balers were in a row, and the chambers had been cleared of all the hay. The mobile welder truck was in position, and the welder was working on the innards of the first baler in line.

The owner of the hay farm drove up and asked what was going on. Ryan (my son) told him that he had discovered a place inside the bale chamber on one baler that was worn to the point of having a catastrophic failure. He checked the other balers, found the same spot in need of attention and had lined up the repair.

The owner checked out the area in question and stated that this was unusual; usually something like that was run until it blew apart in the field (usually in the middle of the night with all the balers going full speed trying to get hay baled ahead of a rainstorm).

To find and repair something mechanical before it completely stops working should be the regular order of how repairs are made.

Mechanical things may give some warning of impending failure. Noise and heat are two indicators that something is wrong. If noise and heat are ignored, the next symptom may be smoke – followed by fire and catastrophic disassembly of the machinery in question.

An infrared non-contact thermometer can be an invaluable tool in determining how hot something is as it runs. Two electric motors running two pumps that are the same should be running at near the same temperature. If they are not, there may be a problem.

Heat, accompanied by noise (especially a new noise) is never good. An electric motor that is properly mated to its task should run at a temperature cool enough to not burn your hand when you place it on the casing of the motor.

All electric motors come with a data plate attached. This lists what kind of electricity the motor needs and how much amperage it should take to run the motor at its advertised speed and power output, which is usually expressed in horsepower. A 10-horsepower motor running a function that needs 12 or 15 horsepower will run hot.

All electric motors come with a data plate attached. This lists what kind of electricity the motor needs and how much amperage it should take to run the motor at its advertised speed and power output, which is usually expressed in horsepower. A 10-horsepower motor running a function that needs 12 or 15 horsepower will run hot.

The parts of the electric motor that create the energy to turn the shaft that does the work never contact each other. The exception to this would be older single-phase motors that still use “brushes.” The bearings that hold the rotor as it turns will eventually wear out and need to be replaced.

The coils (or field) attached to the case of the motor create a strong magnetic force that, when energized, cause the rotor (the part in the motor that turns) to spin.

Alternating current (AC) changing direction at 60 cycles per second causes the proper magnetic force to spin the rotor. (Fifty cycles per second in some other countries; check the data plate before buying a used motor.)

If an electric motor that has been functioning properly starts running hot or starts tripping the breaker, here are some things to check. Use the infrared thermometer to check the temperature of the output shaft of the motor next to the casing of the motor.

If that spot is noticeably hotter than the rest of the motor and what the motor drives, there may be a bearing inside the motor that is failing. Unusual noises usually accompany this.

Hold a wooden broom handle to that end of the motor and the other end to your ear. You will be able to hear the failing bearing shrieking or grinding. If bearing sounds are normal, proceed to the next step. A failing bearing needs to be replaced immediately.

Open the panel that contains the switchgear for that motor. If your switchgear uses fuses rather than circuit breakers, make sure your fuses are good. Low voltage from a faulty circuit breaker (or from any cause) can cause hot motor symptoms.

Use the infrared thermometer to see if any connections are hot. If they are, make sure you have the power turned off and tighten the connection. Electricity does not travel well through loose connections. If tightening the loose connection solved the problem, you’re home free.

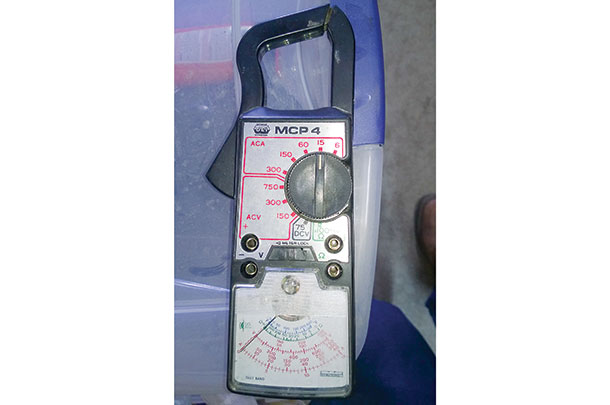

If not, check the data plate on the motor for the amperage needed to run the motor. Then get a tester that includes being able to read AC amperage. To take this reading, a pair of arms from the tester need to surround one wire at a time going to the motor in question.

Most of you will be running three-phase power, so there will be three “hot” leads going to the motor. Place the tester’s arms around one of these leads (turn the switch off first) on the motor side of the switch. Then turn on the switch and record the reading. Repeat for the other two leads.

The reading should be very close to the same for all three and should be at or below the amperage noted on the data plate for the motor. If one phase (one of the three hot leads) reads substantially higher than the others, the motor itself is suspect.

If all read higher, the motor may be running overloaded and is starting to melt down internally. If the motor is OK, there may be an issue with what the motor is turning that is taking more energy to move.

Should your power supplier have had an issue and “single phasing” has occurred, this may damage or destroy motors. Single phasing means that one of the three “legs” of three-phase service has lost power.

Should your power supplier have had an issue and “single phasing” has occurred, this may damage or destroy motors. Single phasing means that one of the three “legs” of three-phase service has lost power.

The remaining two hot legs will not start a three-phase motor and will build tremendous heat. If you have issues with more than one motor that seemed to start at the same time, don’t rule out it being a power company issue.

Electric motors include a fan that is built in to force cooling air through the motor. If the fan is not doing its job, or if there is a build-up of debris inside the motor, then cooling will not occur. Heat is the biggest enemy of electric motors.

Electric motors that run cool should run practically forever. The larger motors will have bearings that are externally lubricated, usually with a standard grease gun. Don’t over-lubricate.

If you don’t have one, I recommend an infrared thermometer for Christmas. (The cost is south of $100.) Then use it to get an idea of what the normal operating temperature of your electric motors is. If you make notes of what normal is, then when something has an issue, you will save time diagnosing the problem.

While you’re at it, get an electrical tester that reads amperage. They should be well south of $200, depending on how many bells and whistles you like. My preference is for one with an analog dial readout.

Get someone experienced to show you how to use one of these. I have unfortunately experienced a 440-volt fireball, and you don’t need to share that kind of fireworks. PD

Brad Nelson is a freelance writer based in Washington.

PHOTO 1: This is the data plate on a 50-horsepower electric motor. The Hz factor at 60 is 60 cycles per second. Motors with Hz 50 are 50 cycle and not usable with the standard 60-cycle power in the U.S. Running in a 460-volt environment, this motor should pull no more than 60 amps per leg at operating speed and a 50-horsepower output. This motor can be wired to run on either 230- or 460-volt systems, both three-phase.

PHOTO 2: These are two examples of infrared thermometers.

PHOTO 3: This is an electrical tester that will read AC current draw through whichever wire the arms encircle. Photos by Brad Nelson.