How low can you go? That’s what producers from California to Pennsylvania are asking after installing a new oval-barrel milking liner designed to operate at very low vacuum levels while maintaining milking speed.

The association between milking vacuum and teat-end health has been well documented. High milking vacuum levels have been linked to hyperkeratosis, tissue congestion, teat end lesions and teat orifice erosion.

High vacuum is a common cause of incomplete milking and can lead to fidgety, uncomfortable cows stepping and kicking in the parlor. On the other hand, too little vacuum or irregular fluctuations can result in liner slip, when air leaks between the teat and the liner.

Liner slip and the accompanying squawking can be merely annoying, or it can be potentially serious and costly as the sudden reversal of milk flow can force milk up into the other quarters, increasing the risk of mastitis.

The challenge is choosing the right liner, vacuum level and pulsation setting that strikes the optimal balance between milking quickly, completely and gently.

Dale Bogart is a Kewaunee, Wisconsin, producer who is successfully balancing those goals.

Co-owner of Deer Run Dairy LLC, about 30 miles outside of Green Bay, Bogart and his partner, Duane Ducat, milk 1,100 cows in a double-20 parlor using an oval-barrel liner recommended by a local dairy equipment dealer.

Since installing the liner in December 2012, Bogart has been able to lower vacuum levels approximately 1 inch compared with his previous milking inflation. Most importantly, he’s seen virtually no difference in milking speed.

“The dealer told me I might milk out a little slower at the lower vacuum, but truthfully, I’m milking the same number of cows per hour as I was with the old liner,” says Bogart. “We’ve had very little slippage, fewer reattachment problems, and the cows are clearly more comfortable. Their teat ends are excellent.”

That opinion was echoed by Tony Louters of Merced, California, who is now running a vacuum level of 11.5 inches since installing the oval-barrel liner last February.

Louters was experiencing multiple cases of mastitis in his 600-head dairy and was struggling to keep his average somatic cell count below 200,000. After installing the new liner and lowering the vacuum level, Louters says he has seen a dramatic change throughout his operation.

“Our somatic cell count dropped by 50,000 within a month, and we’ve seen only minimal cases of mastitis,” he says. “There’s a lot less squawking, the crew isn’t reattaching liners as often and the cows aren’t as kicky. They’re milking out real good and seem very comfortable throughout the entire process.”

Oval-barrel liners aren’t new to the industry but are something most dairymen haven’t seen in years, according to Jeffrey Perkins, general manager at Conewango Products.

He says the liner used by Dale Bogart, Tony Louters and other dairymen was designed specifically to maintain milking speed while operating at lower vacuum levels than are commonly accepted in the industry.

“Of all the liner performance traits important to dairymen, milking speed is at or near the top of the list,” Perkins says.

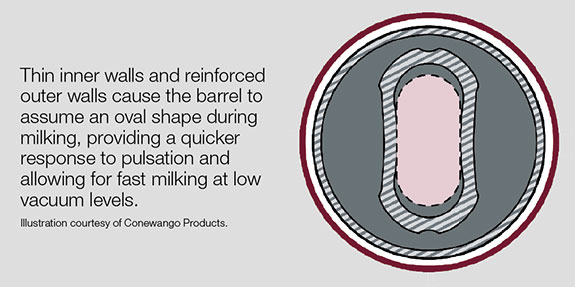

“An oval barrel permits fast milking because there’s less distance for the barrel wall to travel in order to collapse and less vacuum required to open and close. The result is a quicker response to pulsation, allowing for fast milking at relatively low vacuum levels.”

Perkins says the oval shape of the collapsed barrel is made possible by variations in barrel wall thickness.

“Basically, the thin wall sections come together at an engineered collapse point midway down the barrel, while the outer walls resist and delay collapse,” explains Perkins.

“This results in a two-stage, controlled collapse that causes the barrel to assume an oval shape during milking.

The entire length of the channel is subjected to gentle suction throughout pulsation, reducing the risk of slippage and providing a great deal of cow comfort.”

Improved cow comfort is just one benefit realized by lowering milking vacuum levels. Others include reduced risk of ringing, congestion and hyperkeratosis, increased residual vacuum available for massage, easier unit removal and faster tissue recovery.

Greg McCulloh of Mercersberg, Pennsylvania, was able to improve teat-end health significantly after installing oval-barrel liners throughout his double-12 parlor.

“Our veterinarian recommended we switch to a soft rubber inflation that could permit a lower vacuum,” says McCulloh. “Someone recommended the new oval-barrel liner. I showed it to my veterinarian, and he was happy with it, so we installed it throughout the parlor.

We’re now running a vacuum at 11.4 inches, down from 12.2 inches. The cows’ teat-end health has improved and there’s noticeably less squawking.”

Perkins says cows are at their greatest risk for teat end damage at the beginning and end of milking, when teat ends are exposed to vacuum levels very near the line vacuum.

A liner with a tapered oval barrel can reduce teat exposure to higher vacuum levels by permitting cows to be milked at about 1 inch less vacuum, he says. This is especially important for dairies with tiestall barns.

“Dairymen who milk in tiestall barns with a highline usually run line vacuum levels around 14 inches,” Perkins says.

“Lifting milk and keeping liner slip at a minimum is always a challenge in these barns. If a tapered oval-barrel liner can be operated at nearly 1 inch less vacuum while maintaining milking speed, any dairyman would be happy.”

Human comfort matters, too – just ask Jeremy Michalak of Fort Plain, New York. “We were having some really annoying squawking problems with our old liners, especially on the small-teat heifers,” says Michalak. “The inflations would fall off and start squawking like a barn full of chickens.

I installed the oval-barrel liners two months ago, and the slippage – and squawking – stopped overnight. They’re great for the heifers and for the bigger cows, too. But best of all, the barn is now quiet and a pleasure to milk in.” PD

Visit Conewango's website for more information on oval-barrel liners.

—From Conewango Products

PHOTO

Dale Bogart of Kewaunee, Wisconsin, was able to lower vacuum levels 1 inch after switching to an oval-barrel milking inflation, with no change in number of cows milked per hour. Photo courtesy of Conewango Products.