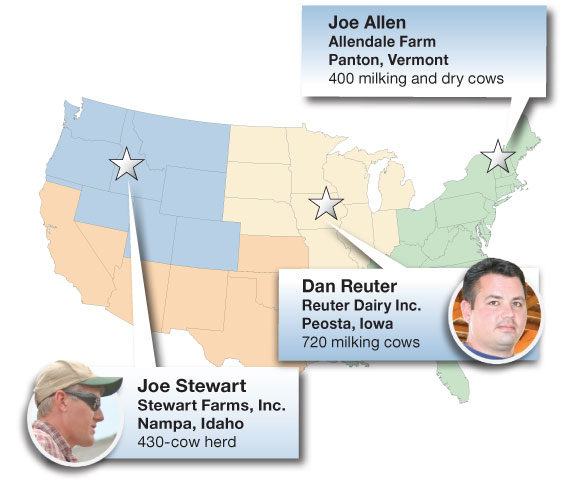

With activity monitoring systems trending across the dairy industry, Progressive Dairyman reviewed how producers are using one specific system that tracks data not previously monitored – rumination activity. SCR Engineers developed the HR-Tag, which tracks an animal’s movement and intensity of the movement. The same tag also records a cow’s rumination activity using a specially tuned microphone. (Click here for more details.) In the following article, we ask users of the rumination tags to describe their experiences with this technology. The roundtable participants are listed below.

- Joe Stewart, an Idaho dairy producer and early adopter of automated heat detection, used the HR tag’s predecessor, the H tag, before the HR tag came along. Although he still uses some H tags, the HR tags help him in detecting illnesses. Previously, Joe used milk meters as a primary source to detect illnesses in the milking herd.

- Dan Reuter, a dairy producer from Peosta, Iowa, says he was using a different activity monitoring system for heat detection prior to switching to the HR tags. He says the concept of rumination monitoring interested him, since he only visually monitored his cows’ rumination before then.

- When Joe Allen first learned about the rumination tags, he says the price was a little out of his budget. However, once the price for the HR tags decreased, he knew this was a tool to implement on his dairy and had them installed.

How long have you had the rumination tags?

STEWART: I had the Heatime system installed in 2006, which had the H tags. The HR tags came along in late summer of 2011. That was when they became available to me. We were testing to see what benefit we could find in these tags.

REUTER: We put them on in February of 2012.

ALLEN: We put in the system about a year ago. We actually had just the H tags until about January, which is when we switched over to the HR tags.

How many cows does your system accommodate?

STEWART: We have the HR tags on about a third of the cows. I put these tags on dry cows and then once they get up past the voluntary waiting period to breed, I switch them back to a normal H tag. It’s a little bit of a hassle that way for me, but we’re really trying to monitor what we can learn from this information.

REUTER: We installed 900 collars right off the bat. We have the tags on 820 of the 840 cows that we own. There are 100 heifers in our breeding yard, with probably 80 of them eligible to be bred, so there are about 80 collars on the open heifers.

ALLEN: We have about 180 HR tags. I have some H tags on our heifers.

Why did you decide to use this system on your farm?

STEWART: I liked the concept of the system because I had done some development with a prior company years ago on monitoring rumination and animal movement. Based on what I had seen there, I thought it was a pretty good opportunity.

REUTER: Previously, I had a different heat detection system, but I was really intrigued by the rumination. One thing led to another, and I jumped over and put these tags on. The biggest reason I installed the system was to save labor time. I was hoping to catch illnesses, like ketosis or milk fever, earlier.

ALLEN: It’s like anything you buy with technology – you always want the latest and greatest. We installed the H tags in mid-September and, at the time, the HR tags were just about to be released.

When the HR tags were offered to me, they were outside my budget. However, when the tags were released in Madison in October, the HR tags were selling for less. I told them that I would have put those in at the lower price. We ended up switching over; they [the system provider] worked with us on that.

How are you using this tool?

STEWART: What we’re doing is looking at this system as a fresh cow tool. When the cow comes fresh, we have another tool now to see if she is coming back on rumination and if she is eating like she should be.

REUTER: Every dairy has its own fresh cow protocols. I have always had my own, too. With these tags, you are able to let them run by themselves to monitor the cows.

You can skip most protocols, such as the calcium boluses, propylene glycols and ketone and temperature checking the cows. You don’t have to do any of that any more, if the rumination climbs every day.

ALLEN: We have been using the system for our fresh cow monitoring outside of the hospital pen. We have a one-group system, where there are about 320 cows in one group and then we have a fresh pen.

When we get slammed with cows in the fresh pen, they are allowed into the big pen. If they get out there and they crash, the box will tell us that the cows are not doing well and should be brought back to the hospital.

How frequently do you collect and review rumination data from cows to detect illnesses or abnormalities?

STEWART: I run a report daily, just like you would on activity for breeding. Believe it or not, cows will go down on rumination and never get sick. My theory is that when we run this report and get these cows, some of them might have eaten a bad spot of feed. Something is not right that day, but they rebound without any treatment. We back that up by looking at milk weights.

REUTER: On the rumination monitoring side, I check the data very thoroughly in the morning and then somebody scans over it quickly at night, just to make sure there is nothing that drops drastically.

ALLEN: I check the data twice a day when I’m looking for the cows in heat. Then, if there are cows that have come through sick, we sort them off. Different than other systems, this is more of a portal system where you really only get the information once the cows have been through the parlor. I check the information after each milking.

How would you describe the learning process in using the system?

STEWART: The rumination takes more interpretation because I think it varies. I don’t think we have any idea what a cow goes through in her day-to-day eating. When the system reports something and we can’t find anything wrong, there’s a learning process there on what we are not finding detection-wise. Finding out how to put that procedure in place and using the information provided is the key.

REUTER: It is very user-friendly. All of the graphs are summed up in a percentage number at the end of the graph that helps direct you in the right way. I would say that within a couple of weeks you have a really good handle on it and then, after a couple of months, you start learning little stuff on how to use or read data.

ALLEN: With a little experience, you’ll have it down and feel comfortable with the system. I think the biggest thing with any of this electronic detection is getting your mind around trusting something that is not another person. You just have to have a lot of experiences where you feel positive that the system really is doing its job. Within a couple of weeks you’ll feel like it really does catch the sick cows.

On a scale of 1 – 5 (five being very easy), how easy to use and decipher is the data for rumination monitoring purposes?

STEWART: I would probably say a 4 out of 5. Let’s say it’s just a little more difficult. There is more to solve but it’s very usable.

REUTER: I would rate it very high, probably in the 4 range.

ALLEN: Five. The system is pretty simple and user-friendly. It sorts the cows out for you so that you don’t have to look through piles and piles of data.

What challenges have you encountered while using your system?

STEWART: One thing I experienced when I initially put these tags in, is that we would get into a situation where I wouldn’t find anything wrong. Then, a day later it became more apparent what the problem was. In some ways, the system is picking up stuff where we were not sure about the problem.

REUTER: The biggest challenge is getting the tag positioned right on the cow. On 85 percent to 90 percent of the cows, you put the tags on and they are fine the way they came from the factory. However, you do have to tweak some of them because the cows’ necks are designed a little different. Sometimes you have to move the monitor up a little bit.

ALLEN: There were some very minor glitches. Once in a while it will freeze up but nothing too crazy. They offer pretty good support, so nothing is down for too long.

Have you run across unique situations in terms of monitoring rumination activity?

STEWART: There have been a couple of times where I have found a sick cow in the dry lot, which is a pen that doesn’t get patrolled very often. There have also been several incidences where it did pick up a mastitis cow before the milk meters did.

What the system has really shown us is how management practices affect your herd. I found that the diet of the close-up pen is really good. We see good rumination up until the cow goes into labor. Appetite problems in the close-up pen are really critical.

If we don’t have a good program – especially in overcrowded close-up pens, which I avoid – I suspect that you would see a larger disruption of rumination through calving. This system really is a source of information that tells you which management practices can cause problems.

REUTER: We ran into a little pocket of mold in our bunker and the cows’ manure became very loose. In the day or two that they had been fed this feed, their rumination skyrocketed, which is the opposite of what you would expect.

We couldn’t see the mold and didn’t know it was there until we started seeing a real problem in the cows’ stools. We assumed that since they dropped in milk production, then the rumination would drop too, but it was very high.

ALLEN: On the rumination side, when your cows are sick and you see them sick, they have probably been sick for a while. This is where we have found this system to be beneficial. We had a cow that the control box picked up showing she had low activity and her rumination had dropped.

We have pretty sharp guys working with us, so I asked one of them about that specific cow. He said she came to the parlor and looked fine. Since the box said she was sick, we went ahead and rounded her up. She was bright-eyed and looked fine. When we took her temperature, she was at 106ºF – she had pneumonia. We treated her and she never lost any milk production.

What advice would you give other dairy producers thinking about rumination monitoring?

STEWART: We have a breeder that is doing a task every day, but we probably don’t always have a person there just to watch rumination. You have to commit resources to use that information because it’s a different task than breeding. You have to dedicate someone whose routine every day is to check this activity and rumination and go investigate. I think this would be a great tool for someone wanting to monitor health but who doesn’t want to invest in milk meters.

REUTER: I would love to tell them just to do it, and that once they put a system in they’re not going to regret it, but this does have a cash flow and there are other factors to consider. As far as our farm, it has saved us a lot on double breeding, shots and a lot of labor on the activity side.

ALLEN: When I bought the system, it made sense to me. The thing I tell people is that if you want to just get your cows bred, get the H tags and put them on open cows. With the HR tags, you should really put collars on your whole herd. The health monitoring is worth every penny, plus you get the breeding data. The system will really replace an assistant herdsman because it works 24 hours a day and catches all of that information. PD