One of the necessary elements of cattle production is vaccination against common diseases. In order to be effective, vaccines must be cared for appropriately. The Code of Federal Regulations states that “biological products shall be protected at all times against improper storage and handling.

One of the necessary elements of cattle production is vaccination against common diseases. In order to be effective, vaccines must be cared for appropriately. The Code of Federal Regulations states that “biological products shall be protected at all times against improper storage and handling.

Completed product shall be kept under refrigeration at 35ºF to 45ºF (2ºC to 7ºC), unless the inherent nature of the product makes storage at a different temperature advisable” (APHIS, 2007).

This code further states that biological products shall be considered worthless after the expiration date has passed.

Producers are usually very good about storing animal health products in refrigerators. However, these refrigerators are often older models and are located outside, in barns or out in the elements. Given these situations, maintaining the proper temperature for animal health products becomes a genuine concern.

Storing animal health products at more than 35ºF can damage the vaccine, as freezing causes the antigen to separate from the adjuvant, thus rendering the vaccine ineffective. This is especially true of killed vaccines.

Retailers are a vital link in the storage and handling of animal health products. It is of little importance how a producer handles a vaccine if the quality or effectiveness of the product is compromised prior to purchase.

Taking vaccine to the animal is the last link in the chain of safeguarding vaccine integrity. For that reason, coolers should be used to protect and maintain vaccines at the recommended storage temperature. Packing enough ice in the cooler to maintain the recommended temperature and protecting the vaccine from sunlight are vitally important.

University of Idaho extension educators, with funding from the Idaho Beef Council, conducted a study in 2009-2010 to identify vaccine refrigerator temperatures and animal health product handling practices of both producers and retailers. There were 127 livestock producers and 43 retail outlets that participated in the study.

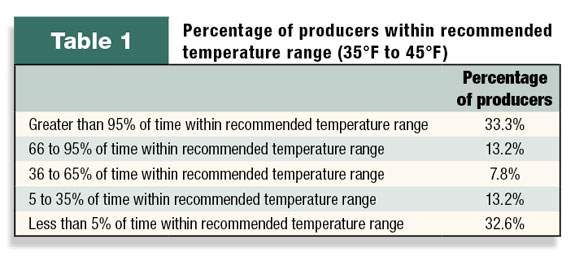

Only one-third of producers’ refrigerators tested were operating in the appropriate temperature range ( Table 1 ). Almost one-third of those tested were operating within the recommended temperature range less than 5 percent of the time.

This suggests that many producers are potentially compromising the effectiveness of the vaccines they store and use. Results from this study are similar to studies conducted in Arkansas and Nevada.

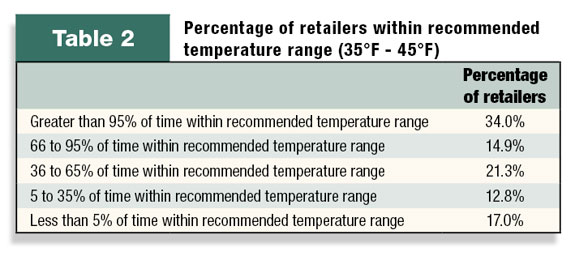

In designing this study, the question was asked about retail refrigerators. It is possible that even though a producer might care for vaccines appropriately, the integrity of the product may have already been compromised by the retailer.

Therefore, we thought it appropriate to include retailers in the study. Of the retailers’ refrigeration units that were tested, only 34 percent were found to operate within the acceptable temperature range ( Table 2 ).

Interestingly, 41 percent of the retailers surveyed reported that they do not do anything to monitor temperatures. Additionally, some of those who claim to monitor temperatures do so by noticing that it is “cool” when they pull out some vaccine.

When asked, the manager of one major vaccine retailer responded, “When we walk in the cooler to fill an order, if it is cold, we know it is working.”

In addition, 40 percent of retailers do not provide any training on vaccine handling for their employees; 33 percent do not provide any training on animal health product questions, though many animal health product retailers provide customers with options to keep products cool during transportation back to the operatoin.

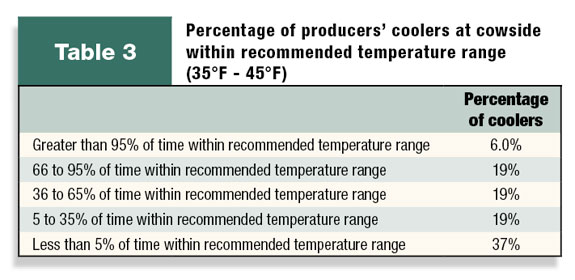

Further temperature monitoring was done in Lemhi County in 16 producers’ coolers as they utilized vaccine cowside. The concern is not only for vaccine utilized, but for the bottles that go back to the refrigerator. Only 6 percent of those coolers held the vaccine between 35º to 45ºF ( Table 3 ).

Information gained from this study has led to the following best management practices for vaccine handling by producers.

When storing vaccine:

• Place a thermometer in the vaccine fridge and check and record temperature on a regular basis

• Check expiration dates on vaccine and discard expired products

• Store vaccine closest to expiration date in the front so it gets used first

• Don’t overstock vaccine because it was a “good deal”

When purchasing vaccine:

• Consider purchasing vaccine in vaccine gun loads

If having it shipped:

• Call order in on a Monday, so it will arrive during the week

• Check shipment as soon as it arrives and refrigerate vaccine immediately

• If any doubt that vaccine has been warm for a time, contact distributor immediately

If purchased locally:

• Take or request a cooler and multiple ice packs to pack vaccine in

Ask retailer the following:

• Do you have a thermometer in the vaccine refrigerator?

• Is the temperature monitored and recorded on a regular basis?

• Is temperature maintained within the recommended range?

• How do you handle the vaccine you receive?

When taking vaccine to the corral:

• Pre-cool the cooler for 1 hour before packing with vaccine

• Depending on how warm cooler is, it will cool 7.9 degrees in one hour

• Include enough ice or ice packs

• Only take enough vaccine for the morning or afternoon shift. Don’t take the whole day’s worth unless absolutely necessary

• Keep the cooler out of the sunlight

• Identify any bottles of vaccine left over (but not opened or partially used) so it gets used first next time

• Discard any opened or partially used bottles

Handling and storing vaccine properly is important so that it maintains its viability and effectiveness. By monitoring the temperature of refrigerators and including enough ice packs in coolers, vaccine can be stored to preserve product integrity and efficacy. PD

The authors are exenstion educators with the University of Idaho. E-mail Scott Jensen at scottj@uidaho.edu

PHOTOS

TOP RIGHT: If this image looks familiar, your storage refrigeration unit may need to be cleaned and organized.

TOP LEFT: In this fridge unit, note the ice accumulation on the top freezer, but no cooling ice on the bottom. Photos courtesy of University of Idaho.