Cows lost condition quickly due to the mud stress, and some farms lost significant numbers of cows or calves. The typical wintering practice of using a “drylot” or “sacrifice area” was not working well. By the end of the winter, there was lots of talk about needing to find a better way to winter the beef herd.

In the last decade, there has been interest in using roofed and concrete feeding pads (often referred to as stack pads) as a way to reduce the mud problem. In theory, they are supposed to take the brunt of the wintering impact and leave damage to pasture and other areas to a minimum. At first glance, these structures look like they might solve the wintering problem but, in practice, have their own challenges.

Once cows are on the concrete and under roof, the damage is mitigated. Getting the cows to these feeding structures has proven more problematic than originally envisioned. Toward the end of last winter, I watched cows on different farms wade through mud to reach feeding pads. In one case, it took a cow over five minutes to walk 150 feet on what used to be well-drained soil. A few of the older cows died on that farm last winter.

Alternatives

Compost-bedded pack barns have been promoted in the last few years as a way to avoid the problems of these feeding pads as well as having better nutrient capture capabilities. Cows are kept in these structures all winter and thus do not have to leave and return. These barns work by having a thick layer of bedding material (usually sawdust) that absorbs manure and urine.

The bedding pack needs to be “stirred,” generally twice a day during the winter season, to help incorporate residues and aerate the pack, helping it compost the material. Cows look clean and comfortable in properly managed pack barns, and it does appear that the major problems found in the previous feeding structures are mitigated.

Challenges

Their problem is: They do not appear to be remotely cost-effective for a typical cow-calf operation. These feeding structures have had the most success by use in the dairy industry. A dairy cow has a relatively high-value product compared to a beef cow. Therefore, what may be cost-effective on a dairy farm may not work for a farm with lower-value products. The rest of this article quantifies the cost-effectiveness, or more accurately lack of cost-effectiveness, of compost-bedded pack barns for beef cow-calf operations.

Cost scenarios

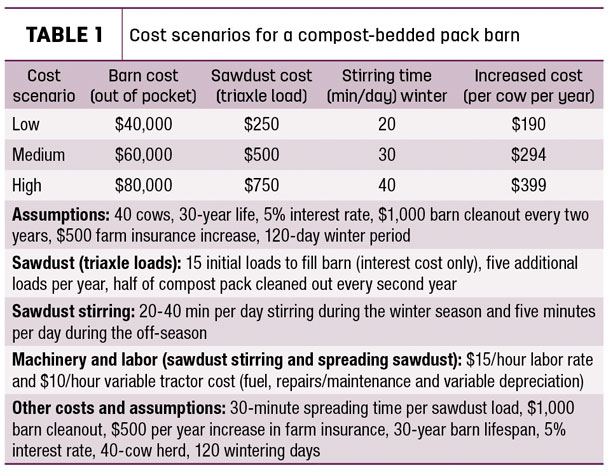

There are many factors that will affect the cost-effectiveness of compost-bedded pack barns. Those with the greatest impact are initial cost of the building (with or without cost-share), the cost of sawdust and the amount of daily “stirring” time it takes to aerate the bedded pack. There are three different cost scenarios for each of these factors to provide a range of costs that may apply in various situations, shown in Table 1.

The resulting costs are expressed on a per-cow, per-year basis. In other words, the results show the costs a compost-bedded pack barn would add to every cow, every year on average, not one-time costs. For perspective, in the current market environment, an average beef cow with an average weaning rate will generate about $600 to $700 in revenue per year. Table 1 shows the results of this analysis. There are three cost scenarios: low-cost, medium-cost and high-cost. Pick the scenario you think is most realistic for your situation.

The medium-cost scenario estimated an additional $294 in cost. That is almost half of the total yearly revenue ($600 to $700) we would expect for a beef cow. It is not even in the ballpark of what could be sustained for a cow-calf operation.

The low-cost scenario estimated an additional $190 in costs; it would effectively add another hay-level cost category to an already profit-challenged cow enterprise. Moreover, this cost scenario is also extremely unlikely. It is essentially assuming 60% to 70% of the barn is cost-shared, the sawdust is almost free (except for hauling costs), and we have the equivalent of a NASCAR-level operator on the tractor stirring the pack twice a day.

The high-cost scenario estimated an additional $399 in costs. This cost level is not going to work for a cow-calf enterprise. Even though this is labeled as the high-cost scenario, it is not an unlikely situation. Sawdust is getting more expensive due to competing and increasing demands.

What is too high of a cost? If you are feeding 2 tons hay per cow per year, this would give roughly $50 to $60 in fertilizer value per cow per year, assuming we recover and effectively utilize 75% of the N, P and K from the hay. There are other potential economic benefits, the most important being improved cow health and reduced hay needs. What would the value of these be? If I am being generous, I might be able to stretch these benefits to $50 to $75 per cow per year. That would mean that, combined with the fertilizer value, the overall increased costs would have to be held to the $100 to $125 level for a compost-bedded pack barn to break even on this cow-calf farm.

What’s next?

For many policy-makers, compost-bedded pack barns are the answer to the winter feeding problem, at least from an engineering standpoint. Is there a way we can make this work from a profitability standpoint? We could subsidize them more: 100% cost-share on the building. With the medium-cost scenario, the 100% barn cost-share would bring the yearly costs per cow down to $197, still not low enough to make it work. However, after these farmers give up on using these pack barns for their intended purpose, they would probably make great machinery sheds or hay storage areas.

If compost pack barns won’t work from an economic standpoint, what are the options for environmental-friendly winter feeding? Bale grazing is one possible solution. Implemented correctly, it will provide great nutrient recycling and will significantly lower machinery and labor costs when compared to conventional hay feeding. Simple, cheap and effective, assuming a farm is already rotational grazing and can provide winter water to at least some of the pastures, there would be no additional supplies required.

The only thing needed would be a change in mindset and management. Could we take part of that $60,000 designated as cost-share for one compost-bedded pack barn and use those funds to provide incentives for a change in management on 100 farms? That might sound radical, but it might just work. ![]()

For inquiries on specific scenarios that you would like to analyze, contact Greg Halich directly.

Greg Halich is an associate extension professor in agricultural economics at the University of Kentucky. Email Greg Halich.