Hybrid impact: starch yield and moisture level

When grain prices are high, dairy producers tend to take a very close look at whether corn particles are showing up in manure. When looking for clues as to why lost particle volume is high, it pays to review hybrid selection. Improperly processed corn kernels passing through cows may be more common in recent years due to corn growers’ hybrid selection to maximize starch yield.

Hybrids with high late-season plant health traits continue to deposit about 1 percent starch in the kernel for every 1 percent drop in whole-plant moisture as the crop enters into maturity stages for silage harvest. Therefore, the decision to harvest the crop at 63 to 65 percent moisture should produce approximately 5 percent more starch compared with traditional silage harvested at 68 to 70 percent moisture.

Equipment inspections

To ensure good kernel processing during harvest, it is important to make sure the entire chopper is in good condition, especially the chopper knives and roller mill. Replace nicked knives and shear bar if showing smooth edges.

Replace rollers, too, if they show signs of wear. Uneven wear of roller teeth may prevent narrowing of the roller gap because the outer edges of the rollers may touch, leaving an undesired wider gap in the middle. The integrity of the working parts of the roller is dependent on types of soils and other environmental factors. Corn grown on sandy soils where wind is quite common will produce more wear and tear on the moving parts.

Make appropriate adjustments after completing inspection of the chopper head and roller mill. The gap setting between the rollers should be 1 to 2 mm, which should crack all the kernels.

Equipment settings — theoretical length of cut

Next, set the theoretical length of cut (TLC) at three-fourths of an inch, which is longer than typical TLC settings for unprocessed corn silage. Processed corn silage requires a chop length that isn’t excessively long to ensure sufficient particle length for ideal packing and fermentation in the silo, yet long enough to provide particles that supply cows with effective fiber for cud chewing and rumination. The feed roll speed determines chop length, so speeding up feed rolls produces a longer chop length.

Harvest moisture also impacts kernel processing. A TLC thumb rule is to shorten the TLC setting when harvesting drier corn; this may lower effective fiber but will ensure adequate packing of drier forage in the silo. Slowing down feed rolls causes less forage to be pushed through the chopper drum, which results in a shorter chop length and a lower tons-per-hour chopper capacity. This requires more time to adequately process the crop.

Equipment settings – roller settings

All brands of harvesters in good working condition can achieve well-processed corn silage, provided attention is given to the nature of the crop being harvested. The grain-to-stover ratio of the crop affects how much grain is going through the roller mill. The higher the grain content, the greater the need for more aggressive processing. Sometimes that means high-starch corn silages going through roller mills with a 1- to 2-mm gap may need a shorter TLC.

If feed roll and roller mill adjustments don’t produce expected kernel processing results, then inspect the differential speed. The upper roller runs faster than the lower roller during processing, and differential speeds of 10 to 15 percent are quite common among the various manufacturers. But when processing expectations aren’t being met, it will help to install a smaller sprocket on the upper roll to increase differential speed to 20 percent or more.

In response to the needs of dairy producers, some manufacturers have engineered roller mills to accommodate a 30 to 50 percent differential speed. Of course, it’s always best to refer to the manufacturer’s specifications to obtain specific information for adjustment settings.

Field monitoring

Because processing effectiveness may change from field to field and from day to day, it is very important to monitor kernel processing throughout silage harvest. During harvest, samples should be checked at least once daily and when switching from one field to the next. In some cases, dairy managers inspect every load coming to the silo for degree of processing.

Establish a field monitoring system during harvest to determine the degree of kernel processing. The dairy manager can inspect loads of forage coming to the silo for kernel damage and then inform the chopper operator if adjustments are needed to improve the degree of processing.

Field monitoring techniques

Some forage experts use a quick and simple on-farm monitoring technique that involves collecting a 32 ounce cup of chopped forage for field analysis. Spread the collected sample onto the cement silo apron or pickup tailgate and manually sift through the entire sample, counting all half or larger kernels. A nicked kernel is not enough; kernels need to be completely fractured.

While this is a qualitative observation, a recommended guideline is that no more than two whole or half kernels should be counted per sample. The actual kernel number can be agreed on by the dairy producer and chopper operator; however, the count should never exceed five whole or half kernels.

Pioneer dairy specialist Dann Bolinger conducted a field test in Michigan to compare the 32 ounce cup technique to commercial laboratory Ro-Tap tests. The tests determine the percentage of starch from a dried sample that will pass through a 4.75-mm screen, which is considered highly digestible starch for cattle. Data revealed that a kernel count of four or fewer produces an ideal 70 percent kernel processing score.

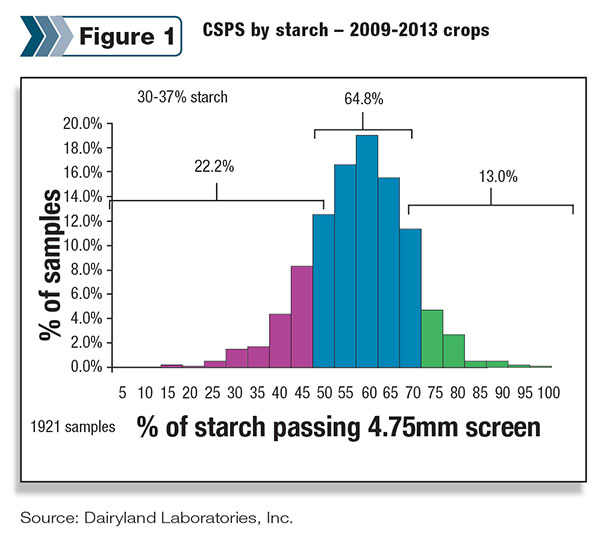

The following table summarizes Ro-Tap corn silage processing scores (CSPS) from Dairyland Laboratories Inc., based on 1,921 corn silage samples from the 2009 through 2013 harvest years. Although many growers have kernel processors on their harvesters, it seems there is definitely room for improvement on kernel damage because a corn silage goal should be to always achieve optimum CSPS.

These are the processing interpretation guidelines for the laboratory Ro-Tap system:

- Less than 50 percent = inadequate

- 50 to 70 percent = normal

- 70 percent = optimum

Most modern-day dairy operations pay a great deal of attention to business management decisions that have a direct impact on the ability to produce milk most efficiently and at the highest level of profitability. Therefore, it makes good business sense that the dairy operation requires well-processed corn silage for maximizing dairy production. And to get that good silage, good harvest practices must be in place from start to finish. FG

Bill Seglar

Veterinarian and Dairy Nutritionist

DuPont Pioneer