When visiting your local farm equipment dealer to buy new tractors and other machines, you’ll find the newest models are equipped with one of two emissions-control options, selective catalytic reduction (SCR) technology or exhaust gas recirculation (EGR) technology.

AGCO was the first agriculture manufacturer to feature SCR clean air technology in tractors, combines and application equipment. e3 is AGCO’s brand of SCR technology and is a system proven to lower emissions of nitrogen oxide (NOx) and particulate matter (PM) from the exhaust gases of diesel engines.

AGCO chose SCR technology as the method it will use to meet the EPA’s Tier III and current Tier 4-I emission standards for off-road diesel engines as well as the company’s platform for meeting Tier 4 final compliance.

AGCO chose this post-combustion, after-treatment process as the most farmer-friendly and most effective approach to EPA compliance.

Because SCR is a post-combustion, after-treatment process that takes place within the exhaust system itself, the process does not get in the way of the engine’s ability to create power and torque.

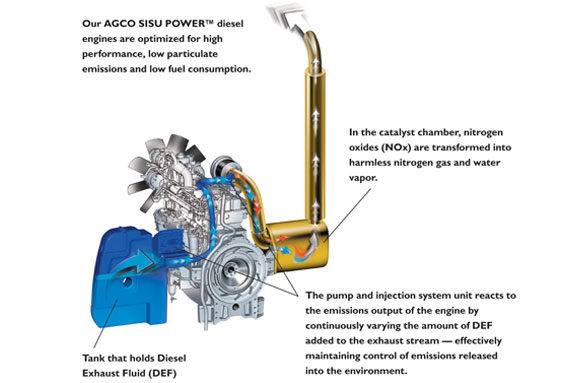

The technology is simple, robust and reliable, consisting of very few parts. The main components include a tank, an injection system and a catalytic chamber.

With the e3 SCR technology, a NOx-reducing agent, diesel exhaust fluid (DEF) is injected into the exhaust gas upstream of the e3 catalyst chamber.

When heated, DEF turns to ammonia and reacts with NOx from the exhaust to convert the pollutants into nitrogen, water vapor and tiny amounts of carbon dioxide (CO2) – natural elements common to the air we breathe every day.

Diesel exhaust fluid is a non-hazardous, high-purity, colorless solution containing 32.5% urea plus deionized water. The DEF is carried in a separate tank on board the tractor and is consumed at a rate of about 3% DEF/diesel.

e3 technology alone can achieve NOx reductions in excess of 90%. It also provides improved combustion which reduces particulate emissions (PM) to 70% below Tier 3 standards.

This emission control system allows engines to function and breathe freely and efficiently. In fact, because SCR optimizes combustion, which in turn lowers heat rejection (wasted energy) by 15%, the cooling package for the engine is smaller and less costly.

Lower heat and greater efficiency also translate to greater component reliability and more hours between oil changes. Finally, SCR technology delivers better fuel economy for lower carbon dioxide emissions. The technology adds nothing to the cost of the tractor, and even eliminates the need for expensive “add-ons” like ECEGR packages and large coolers.

SCR exhaust gas after-treatment is a simple, tried and true process, which was originally used to reduce NOx emissions from coal-fired power plants, and has been widely used in the trucking industry.

Exhaust gas recirculation (EGR) is another nitrogen oxide (NOx) emissions reduction technique used in petrol/gasoline and diesel engines.

EGR works by recirculating a portion of an engine’s exhaust gas back to the engine cylinders.

A portion of the exhaust gases are first cooled through a heat exchanger and then blended with fresh air before being returned to the cylinder.

The exhaust gases have less oxygen and more carbon dioxide than the rest of the incoming air. This lowers the combustion temperature, which results in reduced nitrogen oxides (NOx).

The challenge is to reduce the temperature without having an excessive impact on combustion efficiency.

This approach involves extensive exhaust gas cooling systems, which add cost, recirculation valves to divert a portion of the exhaust or ultra-high pressure injection, and a diesel particulate filter (DPF), which needs active regeneration to avoid blockages which leads to higher fuel consumption. EGR also increases ash and soot in the oil. FG

—Contributed by AGCO. For more information, visit www.agcocorp.com

PHOTO

Emission control technologies often decrease fuel efficiency. Test results from the University of Nebraska Tractor Test Laboratory confirm AGCO’s line of 205 to 275 PTO horsepower rowcrop tractors powered by the AGCO POWER™ 8.4 L engine with e3™ clean-air technology and featuring AGCO’s continuously variable transmission and Dynamic Tractor Management delivered fuel efficiency from 4% to as much as 15% better than other tractors in this category. Photo courtesy of AGCO.