Make sure your engine is running as efficiently as possible with turbo chargers. I think every piece of equipment should have a turbo charger on it and be fuel-injected.

Fuel

Diesel fuel isn’t gas at all, it’s oil. It’s a slow-burning fuel that contains more energy than gasoline does – 147,000 BTUs in diesel compared to 125,000 BTUs in gasoline.

Diesel engines must provide higher temperatures to ignite diesel fuel, but the slower burn gives diesel engines more torque and longer power strokes than gas engines.

Most farmers get the best fuel they can and then they store it. Some try to store their fuel in containers that reflect the sun’s light, not absorb it, to keep the contents from getting hot.

Inevitably the fuel temperature does fluctuate, and you get condensation. The water that ends up in your gas is not good, and if you don’t drain the water you could have problems with bacteria forming between the water and fuel.

To avoid getting water and bacteria in your engine, periodically look inside your tank with a flashlight. If you see clouds in the fuel, you have water.

If the clouds are blackish-green, then you probably have bacteria – which can quickly clog your fuel filters. When you see water in the tank, drain the water out. Also, not allowing your fuel to sit for long periods of time will help you avoid bacteria in your fuel.

Another precaution I take is filtering the fuel as it goes into the tank and then again when I pump it into the equipment.

I would also suggest never letting your tank get below one-fourth of a tank full. Keeping the fuel level above one-fourth of a tank will help your fuel pump last longer and keep the sediments that settle to the bottom of the tank out of the engine.

Turbo charger

Engines run on a four-stroke system or two complete rotations. When the piston comes down, it has to pull the fuel and air into the cylinder. Then it compresses the fuel and air as it comes up. The fuel and air is ignited and the explosion pushes the piston down. When it comes up the second time, the cycle is completed with the exhaust pushed out of the cylinder.

Fuel-injected engines actually push the fuel into the cylinder, rather than relying on the vacuum effect to pull it in. Naturally aspirated engines rely on the atmospheric pressure to draw in enough air to feed the explosion.

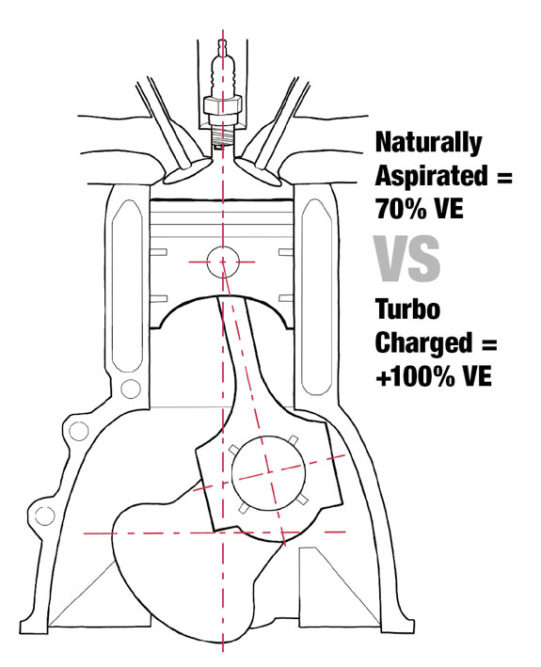

There is a term that sounds really scientific but it explains why turbo chargers are important: volumetric efficiency (VE). It’s the volume that can be pulled in versus the volume it can hold.

For example, the amount of air and fuel that can be pulled in, versus the amount of air and fuel it can hold. Most engines that are naturally aspirated only get 70 percent VE.

Meaning your engine is getting only 70 percent of the power it could be getting. For every 1,000 feet above sea level, take off another 2.4 percent. The pressure goes down the higher you get because the atmospheric pressure decreases, reducing the vacuum effect.

VE also impacts fuel efficiency. If you are wasting 30 percent of your efficiency right off the bat, and then another 2.4 percent after that, how much is it costing you?

Farmers around Fort Collins, Colorado, at 5,000 feet, lose an additional 12 percent – taking a 90 horsepower engine down to 78 horsepower. So by adding a turbo charger, they could improve performance to 120 horsepower and 100 percent fuel efficiency.

A turbo charger actually creates pressure, so you can actually get more than 100 percent volumetric efficiency – sometimes up to 120 percent. That’s possible because it’s packing in the air with the fuel, which causes a more violent explosion.

That added horsepower is great when you are pulling multiple implements. But when you push a turbo charger too high, it will heat up the engine and you will need to watch the exhaust temperatures.

Most new tractors come with turbo chargers, so check your equipment before buying a kit. Also, make sure you follow the instructions so you don’t put your equipment under unnecessary stress and shorten the life of the machine.

Mechanic’s tip

Fuel breaks down over time, so make sure you don’t leave the fuel in your generators for a long time without changing it out. It won’t help keep the dairy going if the fuel has broken down.

Check your fuel at least every six months. There are winter fuels and summer fuels, so make sure you have the right blend so the generator will work properly when it’s needed. PD

- Jim Schlund

- Retired Diesel

Mechanics Professor - College of Southern Idaho