The dairy industry has changed, and we’re changing with it.

Consumers are looking for sustainable, environmentally friendly nutrition produced by people whose commitment to animal welfare and the environment are in line with their own. The systems and products you invest in today will have a lasting effect on your business. So how can you make purchase decisions that increase revenue long-term but also bring you closer to sustainable production?

Sustainability

For consumers, sustainability extends beyond the environment and animal welfare to resource management. They want us to have transparent facilities they can trust will produce food in ethical and respectful ways. For producers, sustainability is more complex. They need to find a way to meet their current needs without compromising their future success or the success of the next generation.

As business owners, it’s critical to engage with the community to build confidence with the consumer. Producers need to make educated decisions and develop facilities that use resource management systems to protect the environment, lower their footprint and make the most out of the resources they use.

Holistic cow comfort

A dairy’s bottom line is directly tied to cow performance, which is affected by several variables from feed and health issues to resting times and heat stress. Each of these variables can drastically affect milk production, and it’s often a combination of variables causing milk loss.

Consider for a moment the impact of heat stress. Most producers deal with a significant drop in production during the summer months. Even mild to moderate heat stress can result in production drops. Studies in Arizona and Saudi Arabia have shown that shade, ventilation and cow cooling can increase milk production up to 6 pounds per cow per day. In a 1,000-cow herd, that’s 42,000 pounds per week. In some cases of heat stress, milk production will drop, but after a period of time the herd will recover and production will return to “normal.” In other cases, the herd doesn’t recover until the subsequent lactation.

Every system put in place is an investment, not only in herd health and well-being but also the productivity and profitability of your facility. Just as you invest in the highest-quality feed and veterinary care, you should be approaching ventilation, cooling and other cow comfort systems with the same holistic mindset.

Instead of looking just at the initial purchase price, dig deeper and look at the long-term operational costs and savings of each system.

Price versus cost of ownership

It’s understandable to be hesitant to purchase when a product’s initial cost is high. We’re all looking for affordable solutions. However, the cheapest option can be the most expensive when you factor in hidden costs like poor performance, energy consumption and labor.

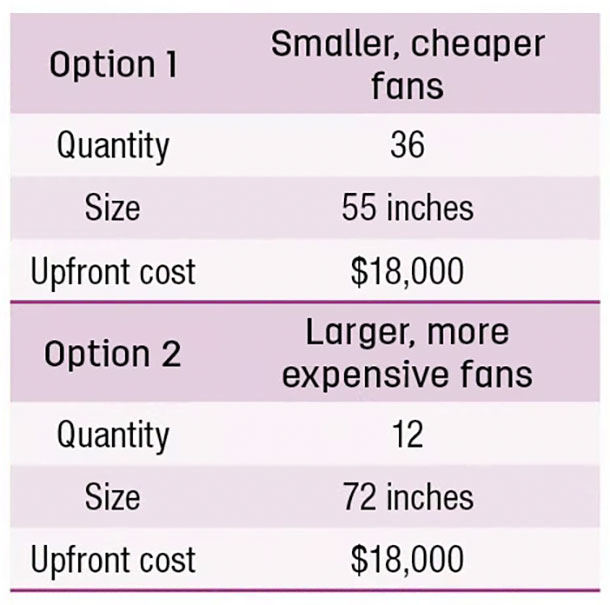

Let’s suppose that a producer looking to purchase circulation fans for their facility has two choices to meet the target air speed and coverage of the barn:

In either situation the initial upfront cost would be $18,000; however, the savings really come into play over the next five to 10 years.

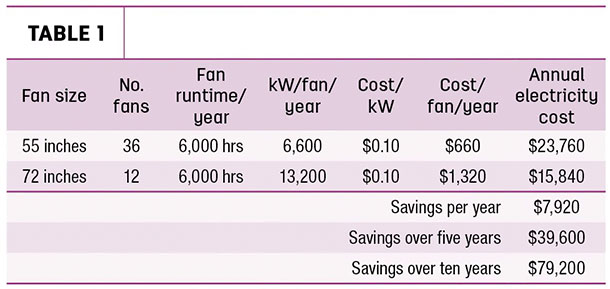

Although it may seem like working with 55-inch fans is the better deal due to the lower kilowatt (kW) consumption per fan, the reality is: Fewer fans with a higher kW usage does work out to be the cheaper option when looking at total annual power consumption. As per Table 1, the power consumption difference is 79,200 kW per annum which, over a 10-year period, is 792,000 kW of power and money saved as well as a step toward sustainability.

Labor

Manpower is always at a premium and typically the second-highest operational cost on a dairy farm. This makes labor a high-priority factor in any solution you choose. If given the option between belt drive and direct drive fans, consider the impact of scheduled maintenance.

Maintenance requirements will vary fan to fan, as will the need for repairs. Cleaning, however, is a requirement for any system to ensure fans are performing at the highest level. Some will opt for a twice-a-year cleaning program using air compressors/pressure washers, whereas others may choose to do a less intensive monthly cleaning regime with one “spring clean” before turning on the fans.

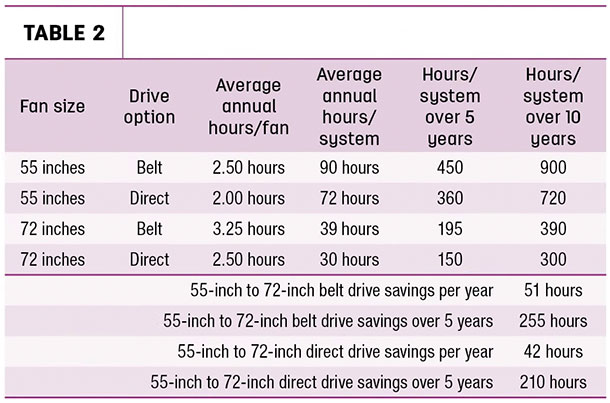

Table 2 highlights the difference in annual manhours required to maintain the fans.

With fewer fans to maintain, the 72-inch fan requires significantly less time over a calendar year compared to the 55-inch fans. In this scenario, the difference between the two fans’ sizes in the belt and direct drive options are 48 hours and 42 hours, respectively.

There are maintenance advantages of the direct drive over the belt drive maintenance. Every year, belt drive fans have one to two greasing intervals. On year two, four and five they will need belt replacements. Add to that the bearing change and tensioner repair, and you have a significant amount of maintenance in each five-year cycle.

It may look like the smaller fans require fewer manhours per fan; however, when you factor in the number of fans needed, the increase is significant. You can save nearly 50% more manhours when opting for the 72-inch direct drive fans.

If the fan you choose has a history of breaking down, the number of manhours increases, as does the potential for early fan replacement. Those, as well as production losses, also need to be factored into the equation. This is why it’s so critical to speak with other producers and learn about their experiences with the fans you are looking to buy before making your purchase.

It’s not just about the cost of labor; it’s also about availability. Your team is busy, and there is always work to be done. How easy is it to pull them off other jobs for scheduled maintenance or repairs? Including labor requirements in the decision-making process will help you make a better decision when designing ventilation and cooling systems.

Automation

A facility’s productivity extends beyond the herd to employees and system efficiency. Easing the burden of menial tasks through automation is one of the easiest ways to free up staff for other jobs. The right control, automating your cooling and ventilation systems, will ensure they’re running when needed.

Variable-frequency drives (VFDs) can increase the life of your fans and provide even more electrical savings. This big step toward sustainability can drastically affect operating costs by reducing motor speeds or turning off the systems based on the environment inside your facility. In our example of 12 72-inch fans, the VFDs would pay for themselves in eight months, after which you would have an additional cost savings of $8,572 or 85,722 kW per year assuming a 10-cent-per-kW cost.

At the end of the day, your return on investment will determine the right solution, and that decision should be based on educated considerations. Take the time to factor in energy consumption, maintenance, early replacement costs, labor and performance as well as that initial capital cost when making your decision. Ask yourself if easy care and hands-off management are just as important to you as increased milk production.

To sum it up, cheap isn’t always the right answer when you’re looking for ways to increase revenue and develop sustainable operations. A sound system designed for sustainable, long-term use will pay back that initial cost more quickly as well as significantly reduce your operational costs.

PHOTO: Beyond the sticker price, consider how much labor, maintenance and early replacement costs will be associated with the choice of fans in a dairy facility. Photo courtesy of Artex.