Optimizing tasks and introducing automation can help with reducing time related to milking, feeding and collecting information needed to make management decisions. This article will cover highlights from the Progressive Dairy Operator 2019 Labour Survey related to labour per cow and technology use on Ontario dairy farms, which represents 117 dairy farms in Ontario.

Labour per cow per day is a calculated time that encompasses all employee time (non-related employees, family members and owners) working on the dairy farm. The tasks in this calculation include calf care, milking, herd management, feeding and other dairy-related tasks. This number does not include field work associated with the dairy farm.

The average labour per cow per day was 11 minutes for all herds that participated in the survey. The average labour per hectolitre of milk produced in the dairy was 32 minutes plus or minus 18 minutes based on an average cow milk production of 34 litres per day.

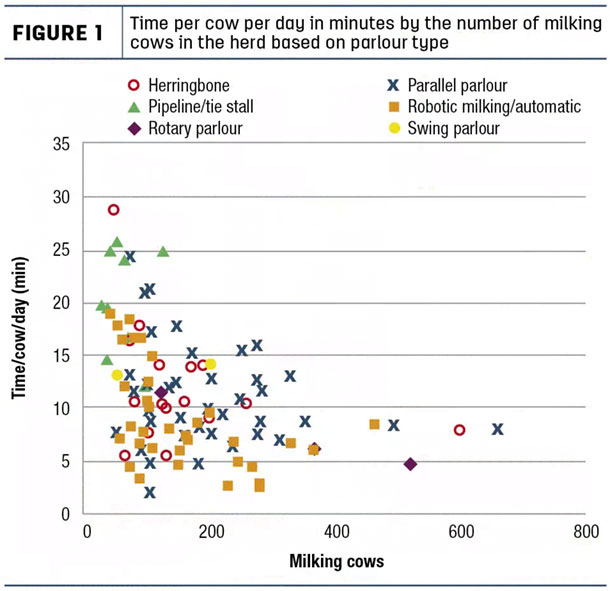

Categorizing labour based on herd size, the average time per cow per day was:

- 25 to 100 milking cows: 13 minutes (range of two to 28 minutes)

- 101 to 150 milking cows: 11 minutes (range of two to 25 minutes)

- 151 to 250 milking cows: nine minutes (range of two to 15 minutes)

- 251 to 650 milking cows: eight minutes (range of two to 16 minutes)

Categorizing labour based on parlour type, the average time per cow per day was:

- Herringbone parlour: 12 minutes (range of five to 28 minutes)

- Parallel parlour: 11 minutes (range of two to 22 minutes)

- Pipeline/tiestall: 17 minutes (range of four to 25 minutes)

- Robotic milking: eight minutes (range of two to 19 minutes)

- Rotary parlour and swing parlours had too few participants for analysis.

Labour per cow per day varied based on both herd size and parlour type, as shown in Figure 1.

There was a relationship between herd size, the type of milking system used on the farm and technology adoption. For instance, farms milking 25 to 100 cows have a higher proportion of pipeline/tiestalls. Robotic herds had the greatest labour efficiency in terms of parlour type, which was related to herd size. Herds with robotic milking systems did spend more time inputting and reviewing data at 7.4 hours per week, while other parlour types averaged 5.1 hours per week. Time per cow per day is an important measure to calculate, as it allows dairy farms to evaluate which tasks require more labour and attention, and which tasks need to be optimized to more efficiently utilize time and labour.

Technology use

The survey also asked about the use of technology on-farm, including both sensor-based technologies (e.g., activity monitors) and automation (e.g., automated feed pushers). Participants were asked what technologies they are currently using on their farm. The most common technologies used were:

- Activity monitors (82%)

- Sexed semen (77%)

- Automated feed pushers (39%)

- Rumination tracking (38%)

- Genomics (34%)

It was common for farms to utilize more than one technology on-farm, with an average of 3.4 technologies currently used. (Most farms reported having three to four technologies.)

Farms that indicated having adopted four or more technologies demonstrated increased labour savings per cow [three or less technologies (59 farms) averaged 12 minutes versus four or more technologies (58 farms) with an average of nine minutes] and increased labour savings per hectolitre of milk produced [three or less technologies (39 minutes plus or minus five minutes) versus four or more technologies (25 minutes plus or minus three minutes)].

Survey participants indicated the most useful technology on the farm was activity monitors, which helped with making day-to-day decisions. Robotic milking was the second- most commonly favourite technology, which participants indicated as saving time and labour as well as helping with day-to-day management decisions on the farm. Adopting technologies on the farm will not necessarily save labour immediately.

Producers must learn how to use that technology and the information it provides to decrease labour needs by increasing production, reducing disease prevalence and helping make management decisions more proficiently. In addition, evaluating where labour is being used on the farm and where improvements are needed can help you prioritize what technology is best suited to improving efficiency in the herd.

Broader technology adoption is fostered through producers who introduce and try new technologies on their farms. These individuals have a higher comfort level with attempting new technologies and taking risks. Everett Rogers’ book Diffusion of Innovation separates people into five different categories of technology adoption.

- Innovators (4% of survey participants) are the first people to try a new product or service and are accepting of the risk that a technology may not meet their expectations.

- Early adopters (48% of survey participants) are like innovators in that they will try new technology but will wait until a technology has shown to meet most of its expectations. This group will promote the use of a technology or service to their peers.

- Early majority (34% of survey participants) will follow the lead of the early adopters and the innovators and adopt technology once it has shown its usefulness and there is little risk that the technology or service will not meet expectations.

- Late majority (5% of survey participants) adopt innovative technology later. They tend to be skeptical of innovative technology and will only take up a technology when there is no risk of it not meeting expectation and on the advice of others including family members and peers.

- Laggards (4% of survey participants) are resistant to change and will stick to traditional ways of doing things.

In the survey, the early adopters and innovators had more technologies they were using on the farm (4.13) than the early majority, late majority and laggards (2.68) shown in Figure 2.

This indicates survey participants are more likely to adopt or try new technologies.

In conclusion, understanding labour needs per cow per day and where time is being prioritized on the farm can help with optimizing tasks and workflows. This will also help with prioritizing what technologies might be worth considering and evaluating for use on the farm. ![]()

Marlene Paibomesai is a dairy specialist with the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA) and serves as an adviser to the Progressive Dairy Operators (PDO) board of directors.

References omitted but are available upon request. Click here to email an editor.