Forage quality is the Achilles’ heel for any ruminant nutritionist. The better the forage coming out of storage, the better the nutritionist.

Silage management is not easy and involves many complex interactions to get the greatest return from the significant investment in growing, harvesting, storing and feeding quality forages.

To store any kind of feed, either air or water must be removed to preserve nutrients. In the case of water removal, the feed is dried to a point that stops microbial activity. Then the feed can be stored. In the case of air removal, nutrient preservation is dependent on anaerobic fermentation creating an environment where microbial activity is almost eliminated or mostly dormant. When exposed to air again, aerobic microbes will reactivate. This reactivation consumes valuable nutrients and decreases storage life.

During either of these processes, there are opportunities for failures, and these missteps can have serious effects on the rumen – and on production and profitability.

Mistake No. 1: Diluting spoiled silage

It’s tempting to feed a little bit of spoiled silage. After all, every inch of silage represents a lot of hard work. However, dilution is not always the solution to pollution. A study to determine the effects of surface spoilage fed in a corn silage-based diet was reported in 2000. This is a pivotal study because it actually measures the impact in live animals.

Twelve rumen-cannulated steers were fed varying proportions of spoiled and normal corn silage. The four experimental rations contained 90% silage and 10% supplement (dry basis). The silages in the rations were one of the following:

a. 100% normal

b. 75% normal and 25% spoiled with a slimy layer of 5.4%

c. 50% normal and 50% spoiled with a slimy layer of 10.7%

d. 25% normal and 75% spoiled with a slimy layer of 16%

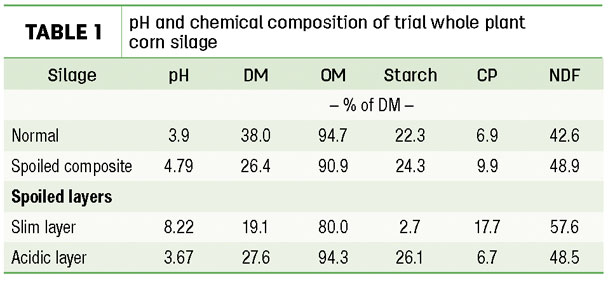

After 90 days, the bunker silage had lost 14 inches. What remained was 7 inches of slime (non-digestible fibre and water) and about 15 inches of wet, high-acid corn silage with a bright yellow to orange colour, a low pH and a very strong acetic acid smell. The pH and chemical composition of the whole-plant corn silages fed are shown in Table 1.

The mixture or composite represents the spoiled silage as it was actually fed in rations B, C and D.

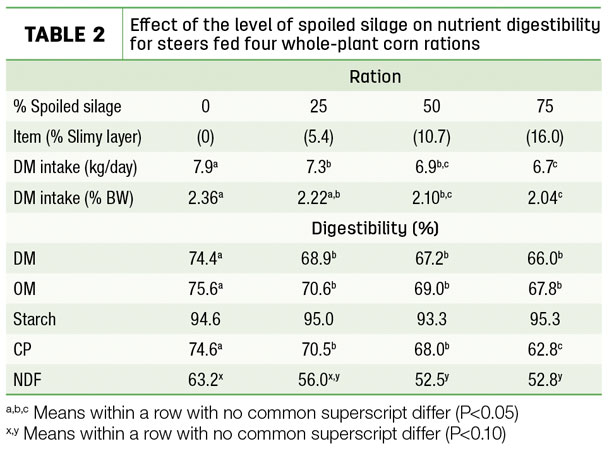

The addition of spoiled silage decreased crude protein (CP) digestibility in a linear manner, and surface spoilage had large negative effects on dry matter intake (DMI) and digestibility of dry matter, organic (OM) and NDF (Table 2).

The biggest change in NDFd was with the first and smallest inclusion of spoiled corn silage. The difference on 7.2 units of digestibility represents a lot of milk or growth.

When ruminal contents were evacuated, the spoiled silage had partially or totally destroyed the integrity of the forage mat in the rumen.

Mistake No. 2: Ensiling wet forage

When alfalfa, grass or cereal grain silages are harvested at higher-than-recommended moisture levels – and ensiled without a good inoculant – a clostridial fermentation will likely result. This leads to the creation and accumulation of biogenic amines and ammonia. Many have odours that their names aptly describe. The ones most commonly associated with silage fermentation are putrescine, cadaverine and histamine.

Another pivotal study looked at substituting direct-cut alfalfa silage with alfalfa hay and its impact on digestive function and intake. Ruminally and abomasally cannulated steers were fed diets consisting of alfalfa as hay or silage, corn silage and concentrate. The DM from alfalfa silage was substituted at 0%, 33%, 67% and 100% for DM from alfalfa hay. Forage content of the diet was 50%, and 60% of that forage was alfalfa hay or silage.

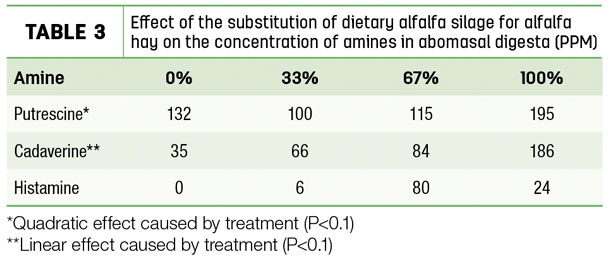

The concentrations of putrescine and cadaverine in abomasal digesta increased as more direct-cut alfalfa silage was included in the diet (Table 3).

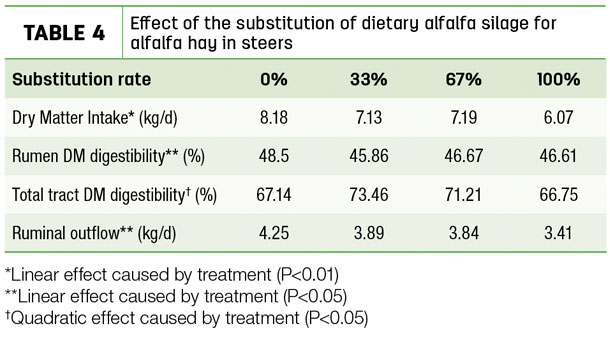

As the levels of putrescine and cadaverine increased in the diet, DMI decreased by more than 25% when all the hay in the diet was substituted for silage. In addition, rumen DM digestibility and outflow decreased linearly as silage replaced more of the hay in the diet (Table 4).

Another study measured rumen contractions after infusing direct-cut alfalfa silage seepage into the rumen of sheep. The infusion began 10 minutes before feeding was offered. Intake decreased for 1.5 to nine hours after infusion of silage juice. Rumen motility decreased. A synthetic silage juice containing identical amounts of VFAs, lactate, soluble carbohydrates, pH, osmolality, ammonia, nitrate and nitrite to actual silage juice only accounted for 40% of the intake depression when similarly infused. Something else in the silage juice contributed to the decrease in intake and rumen motility.

There is much that has been written on silage fermentation and the management practices that make excellent silage. Even though it is a simple process, it needs to be controlled to provide consistent, high-quality feed.

From a practical standpoint, diluting contaminated silage with mould-free silage is not a healthy solution in highly productive cattle. Proper silage management can support optimal rumen function. To achieve this, the fermentation process must be controlled and not left to chance. Rapid reduction in pH at ensiling and improved aerobic stability at feedout are the hallmarks of well-controlled silage fermentation and quality feed for cows.

Forage quality cannot be improved through the silage process; it can only be preserved or destroyed. Garbage in equals garbage out. ![]()

Andy Skidmore received his DVM from Kansas State University and his Ph.D. in animal sciences from Cornell University and is employed by Lallemand Animal Nutrition, North America as a technical services – ruminant team member.

Renato Schmidt received his Ph.D. in animal nutrition from the University of Delaware and is employed by Lallemand Animal Nutrition, North America as a technical services – forage team member.

References omitted but are available upon request. Click here to email an editor.

-

Andy Skidmore

- Technical Services – Ruminant

- Lallemand Animal Nutrition, North America