For any processing protocol to be successful, many things need to be in place before new cattle arrive at the feedyard.

Most important, the feedyard veterinarian, nutritionist, management/ownership and all feedyard personnel must work together as a cohesive team.

This should begin with frequent meetings to discuss the type and origin of cattle the yard is looking to procure. Goals should be discussed and set with frequent review of protocols.

Also, no changes to the protocol should be made until the entire team is in agreement.

Processing preparations

To maximize the success of your processing program, there are many preparations that should be made before cattle arrive. Consider these seven key areas:

- Animal care:

- Ensure an adequate supply of fresh feed and water for newly received cattle.

- Keep receiving and holding pens clean and dry.

- Facilities:

- Maintain working facilities so cattle can be handled in a quiet, low-stress manner.

- Always take the welfare of cattle into consideration when designing and looking at your facilities.

- Inspect equipment and facilities daily to look for areas that need repaired to prevent any unforeseen foot or leg injuries or any unnecessary bruising. At processing, this may result in a carcass blemish that isn’t revealed until slaughter – and this negatively affects beef quality.

- Employee training:

- All employees involved in processing must be properly trained and Beef Quality Assurance (BQA) certified.

- Work closely with your veterinarian, as he or she is your best source for information and training.

- Vaccine storage:

- Keep a thermometer in your refrigerator or cooler so vaccines are stored within the proper temperature range.

- Remember that heat and sunlight rapidly deplete the viability of vaccines, so always keep them on ice in a covered cooler.

- Never mix up more modified-live viral (MLV) vaccine than what you can use in 60 minutes or less.

- Syringe hygiene:

- Take syringes apart and wash in extremely hot water between groups of cattle. Note soap and disinfectants may render a MLV vaccine inactive.

- SubQ administration:

- For maximum beef quality, select subcutaneous (SubQ) products when possible.

- Follow all product label directions, as well as all applicable guidelines of the Food and Drug Administration, U.S. Department of Agriculture and Environmental Protection Agency.

- Administer all products in front of the shoulder (never in the rear leg or top butt). When administering SubQ, a 16-gauge by 5/8-inch disposable needle is ideal.

- Change needles at least after every 10 head but follow the recommendations of your veterinarian.

- Record-keeping:

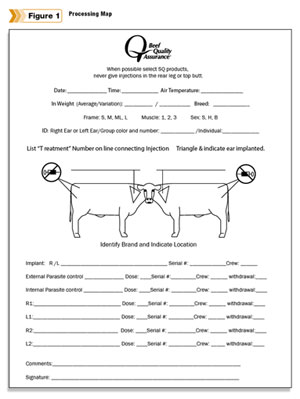

- Maintain adequate records for each group of cattle. Record the product used, the serial number, expiration date (if possible), where it was administered and which crew member performed the procedure.

- Use a processing map, such as the one in the BQA Manual, to track this information.

Additional protocol considerations

When meeting as a team, first discuss how and where cattle will be procured. Will they be strictly commingled sale barn or order buyer derived?

Will they be from a video auction or direct from a ranch? Will they be backgrounded or preconditioned?

What is the ability of the yard to handle various types of risk in cattle, and what is the overall level of expertise of the feedyard crew?

Along with making your pre-arrival preparations, consider other details, such as weather and cattle origin, with your team.

Never process cattle when it is raining or cattle that are wet or damp, as this will increase risk of reactions and blemishes at the injection site.

Also, avoid processing cattle during extreme heat and high humidity to avoid heat stress losses.

It’s important to know the vaccinations and other procedures conducted at the point of origin because they may not need to be repeated on arrival at the feedyard.

Some people work at the point of cattle procurement to vaccinate with a respiratory viral vaccine and a long-acting antimicrobial to control bovine respiratory disease (BRD) before and during transportation.

Often, cattle are treated with a fast-acting oral anthelmintic to reduce the internal parasite load and help reduce the stress level on the calf’s immune system.

Always discuss vaccinations, parasite control and implant protocols with your veterinarian and follow their recommendations.

Processing protocol treatments

Each producer must discuss his or her processing protocols with the veterinarian and decide what is right for the operation. Many protocols generally address one, or all, of the following cattle health issues:

- Viruses

- Infectious bovine rhinotracheitis (IBR)

- Bovine viral diarrhea (BVD) Types 1 and 2

- Parainfluenza3 (PI3)

- Bovine respiratory syncytial virus (BRSV)

- Respiratory bacteria

- Mannheimia haemolytica

- Pasteurella multocida

- Histophilus somnus

- Mycoplasma bovis

- Long-acting antimicrobial for control of BRD

- Clostridial diseases

- Internal and external parasites

- Implants for increased productivity

Elements of a good processing protocol

Planning ahead is very important and there is no specific protocol that fits all needs.

Work closely with your veterinarian and the rest of your management team to develop the best protocols for your operation, as well as to evaluate your successes or failures, and modify the protocols as needed.

Proper planning, accurate timing of vaccination and minimizing stress on your cattle through shipment and handling are just as vital to processing protocols as having a well-rounded, educated team.

All elements together will help lead to a successful outcome.

Click here or on the image at right to download a pdf.

Always follow BQA guidelines for each procedure and remember that the consuming public is counting on you to deliver a safe and wholesome product. With proper procedures and a knowledgeable team, we all can be successful. ![]()

PHOTO

Always take the welfare of cattle into consideration when designing and looking at your facilities. Photo courtesy of Progressive Cattleman staff.