The safest, most economical and effective way to contain your beef cattle is with an electric fence powered with a high quality fence charger. A cow that encounters an electric fence receives one pulse of electricity per second, providing the fence has been effectively grounded.

An electric pulse occurs when the cow comes in contact with both the ground and the wire. When this happens the circuit is complete and the cow receives an electrical shock. Without effective grounding the circuit cannot be complete and the fence becomes ineffective as a method of containing cattle or keeping out predators.

“For your fence to function correctly, your earth (ground) system must be perfect,” wrote Vaughn Jones. “But very few are, despite the instructions provided with most energizers.”

Ground conditions: Moist and wet or dry and rocky?

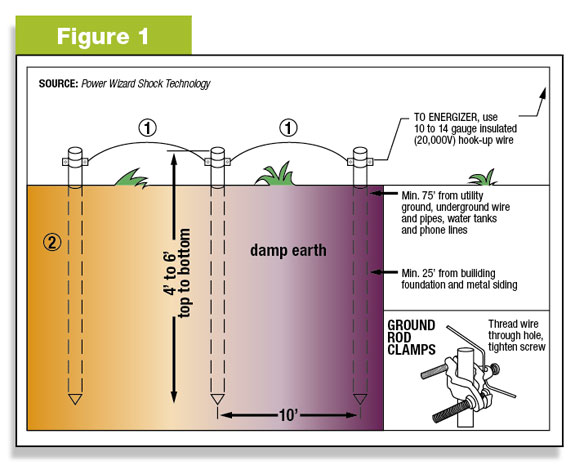

Before you start to create an effective grounding system for your cattle ranch, consider the ground conditions (see Figure 1). To be effective, the rods should be inserted into ground that is continually moist. If your ranch consists of dry or rocky soil, seek an area of your farm that has some degree of moisture or that can be moistened during drought conditions. Or consider adding an earth wire return system.

Ground System Installation

- 10 to 14 gauge galvanized fence wire.

- Ground rods 4 to 6 feet long by one-half inch (or more) in diameter, galvanized steel rods.

IMPORTANT: Avoid SANDY, DRY and ROCKY soil.

How to effectively ground your electric fence

Grounding your electric fence requires the installation of a ground system that is positioned within 75 feet of your fence charger.

What is a ground system?

The “ground system” is a series of highly conductive rods driven into the soil and then connected by wire to the ground terminal of your fence energizer. The ground system collects electrons from the soil to complete the circuit needed for delivering an effective shock to your animals.

Locating your grounding system

Locate an area of soil for placing ground rods that contains good conductive earth (not sandy or rocky). Soil that is moist throughout the year is best. The ground system should be located within 75 feet of your fence energizer and at least 25 feet from buildings with metal siding (see Figure 2).

Locate the ground system a minimum of 75 feet away from:

- Utility company (electric, gas, water) ground system

- Underground water pipe

- Metal water tanks

Energizer Installation

- Insulated hook-up wire (20,000V)

- Galvanized fence wire

- 4 to 6 feet long by one-half inch (or more) in diameter ground rod

- Ground clamps

- Power supply – use power supply specified by label on energizer only

- Ground rods MUST be 25 feet minimum from building foundation

Note: The hot on an energizer is usually either indicated by a red knob or a lightning bolt symbol (↯) and the ground is usually indicated by a black knob or an arrow symbol (⏚).

Troubleshooting ground conditions

Troubleshooting ground conditions

If the soil is moist during most of the year but suffers from period of dryness in the hot, summer months, it is possible to water the grounding system to keep a strong electrical connection.

Tip for dry soil: Ranches with extremely dry ground conditions can include a bentonite mix to their grounding system to help absorb moisture. Create a paste or gel-like consistency from powered bentonite and water and pour down a 3-inch diameter or larger holes and insert the ground poles in the center.

Add grounding rods: Another solution for rocky, dry or sandy soil is to add more grounding rods in the grounding system. A standard grounding system contains three, 4 to 6 foot by one-half inch galvanized grounding rods 10 feet apart. For dry soil, add an additional grounding rod to increase the energy connection that completes the circuit between the fence energizer, the ground and the cow.

One of the existing strands of fence can be grounded but a better solution would be to run a bare galvanized wire along the fence line and just below the surface of the dirt. Run a grounding wire parallel between the electric wires and drive a 4- to 6-foot galvanized steel or copper rod every 1,300 feet. By using this system to ground the electrical fence, the electricity is able to effectively shock the cow without the current traveling underground. The wire should be attached to each post for the best results.

Installing the ground system

Supplies needed:

- Three 4- to 6-foot long by one-half inch (or more) in diameter galvanized steel rods (or more if poor ground conditions)

- 10 to 14 gauge galvanized, insulated (20,000V) fence wire

- Sledge hammer or ground rod driver

- Ground clamps, one for each rod

- 3 or 4 steel stakes

- Digital voltmeter made for electric fences

- 12-inch metal stake

Drive three, 4 to 6 foot by one-half inch (minimum), galvanized ground rods 10 feet apart in a straight line or a triangle pattern in the selected ground area. Leave 6 inches above the ground for securing ground clamps. The ground rod may be driven in at an angle if necessary. Connect the ground rods, in a series, with one piece of continuous 10 to 14 gauge galvanized wire. The ground hook-up wire should be equal to or larger than the diameter of the fence line wire. (See Figure 3.)

Ground Return System

- Galvanized fence wire

- Ground rods

WARNING:

Never use an existing grounding rod that is connected to another electrical device or use a water line to ground your electric fence.

Testing your electrical current

Testing your electrical current

The performance of your fence charger’s ability to keep your cows, cattle and other livestock safe and contained relies on the effectiveness of your ground system. The ground system is a critical part of the connection that completes the circuit between the electric fence and your cattle. Verifying that your ground system is working is a “must-do” stage of the installation of your electric fence (see Figure 4).

Testing the ground system

Test periodically

Once your ground system is installed and the electrical current is verified you will still need to periodically check to make sure the level of electrical current is effective enough to contain your cows.

Check your ground system condition with a voltmeter once during the driest period and once during the wet season each year to insure adequate grounding of your electric fence.

During dry seasons or during seasons when there is excessive growth or vegetation on your fence line, it may be necessary to upgrade your ground system by adding ground rods.

Verify your ground system works

- Unplug your fence energizer.

- Place the fence under heavy load by “shorting” the fence as follows: At a location on the fence at least 100 yards from the energizer, lean 3 or 4 steel stakes or unpainted T-posts against the “hot” wire of the fence. Alternatively, some people have found a successful method is to push several pieces of fence wire into the earth and wrap the opposite ends around the hot wire.

- Plug the fence energizer in and check the fence line voltage with a digital voltmeter. You want to see that the voltage has dropped below 2,000V due to shorting the fence. On some high-powered fence energizers you may not be able to short the fence below 2,000V. However, you can still test them at a higher voltage.

- Continue to short the fence by leaning steel posts or by making wire connections to ground at 100 yards distance or more from energizer until the fence line voltage drops below 2,000V.

- You are now ready to test the energizer ground system. Connect one lead of the digital voltmeter to a 12-inch metal stake driven into the ground 3 feet away from the last fence energizer ground rod. Connect the second lead to the ground rod furthest from the energizer. The voltage reading should ideally be zero or no more than 200V.

- If the digital voltmeter reading is under 200V, your ground system is adequate and you will get near maximum performance from your electric fence energizer.

- If the reading is above 200V, then your ground system needs improvement.

You must:

- Add more ground rods connected in series, ten feet apart and/or

- Move your ground system to moist soil until the ground system voltage is below 200V.

Most common grounding issues

The most common misconception by farmers, ranchers and weekend hobbyists is that the grounding process isn’t important. The cow completes the circuit so that the electrons flow from the fence energizer, through the soil to the grounding rods and up into the cow’s legs to where the cow is touching the fence with its nose or body, producing an electrical shock. Therefore, the effectiveness of the ground system is extremely important.

Notes: Make sure you test your electric fence with a digital voltmeter on a routine basis. This is especially important when vegetation is high and touches the fence or when the ground is very dry or very damp.

Following are some common grounding issues:

- There is a bad wire connection to the ground wire. Check to make sure the wire is securely fastened and isn’t frayed.

- The dry soil condition of the farm requires additional grounding rods.

- The wrong type of rod was used for the grounding, i.e. pipe or rebar. It needs to be galvanized steel at least 4 to 6 feet long.

- The rods weren’t long enough. In the case of dry soil, it may require 6 to 8 feet of galvanized steel to reach a moist area of ground.

- The ground conditions changed and due to extreme draught or heavy vegetation, additional rods need to be added.

- The wrong type of wire was used. Using household or industrial cables made for only 400V are not enough to support the system. Make sure you use 10 to 14 gauge insulated lead-out wire rated at 20,000V.

Conclusion

Creating and testing your ground system is a critical step to ensuring your fence charger provides the necessary jolt of energy to get your cow’s attention and keep them from ramming or damaging the fence line or themselves.

Four main points to remember:

- It is the connection of the cow with the ground and the hot wire that completes the circuit to allow an effective shock to be delivered.

- Install the ground system on a consistently moist area of your farm within 75 feet of the fence energizer.

- Use the proper rods and wire when building your ground system.

- Test periodically to ensure the electric connection is effective during dry, damp and high vegetation seasons.