Some of the most common questions I hear from clients are: How can my employees milk faster? Should I expand my parlor to milk more cows? How can I milk more cows when we can barely finish milking what we have?

The number of operators, facility design, milking routine, milking procedure, condition of the milking equipment and the type of bedding used on the farm are some of the main factors to consider when finding the answer to those questions.

Maximizing parlor efficiency and matching it up to labor and facilities applies to all farms regardless of size and will determine the profitability of the farm.

Before considering efficiencies, I recommend dairy producers have a well-written set of milk quality goals. For example:

- Less than 2% of cows with clinical mastitis per month

- Less than 5% culled cows for mastitis

- Greater than 85% of the herd with linear score 3

- Maintain 150,000 or less bulk tank somatic cell count (SCC)

Next, observe what is happening in the parlor and why those things are happening. Understanding cow flow, the time it takes to turn a side, lag time (the time from stimulation start until unit attachment) and unit on-time will help determine some of the things to implement to match efficiency in the parlor with labor and facilities.

One change leads to another

Most of the parlors I have been involved with over the years have gone through a progression, with many different challenges as they grew in cow numbers, employees and facilities. Part of my job was to find a balance among the three areas while maintaining farm profitability.

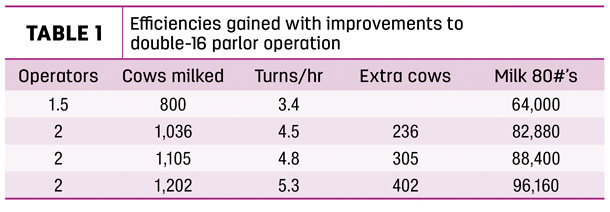

In one example, a farm with a double-16 parlor, sand facility, used one full-time operator in the parlor and a second operator splitting half of the time milking and the other half bringing cows to the parlor, scraping pens and cleaning stalls. At this farm, developing a milking routine for both operators to follow was crucial to be able to do 3.4 turns per hour to milk 800 cows in 7.5 hours 3X.

The second step for this farm was to add another building to house 400 more cows. Now, adding a third operator made things more efficient. With two full-time parlor operators and a third person bringing up cows, they were able to achieve 4.5 turns per hour, and the farm was able to milk 236 more cows. Milking cows in a parlor is an ongoing process; training and retaining employees consistently is crucial to the success of any operation. As operators were trained and became more familiar with the goals and expectations of the farm, they were able to turn the parlor 4.8 turns per hour or 69 more cows per shift.

With the help of the milking equipment company and upgrading certain components of the milking equipment, the farm was able to milk 97 more cows per shift or 5.3 turns per hour (see Table 1).

The economic impact of maximizing the parlor with the same number of operators in the same facility was:

(400 cows x 80 pounds of milk) ($17 cwt milk) = $5,440 per day or $163,200 per month

Lag time makes a difference

Lag time makes a difference

If we want to become more efficient in a parlor, some of the things to question are: Is the number of operators right for the number of cows in the facility? Is the facility milking enough cows? Do pen numbers match parlor size? Is the current milking routine efficient? Is the milking routine currently done in the parlor the same as the protocols established by the farm? Answering these questions will help determine which direction to start working on to become more efficient.

The best way to increase parlor efficiency is to maximize milk letdown and avoid overmilking. In order to maximize milk letdown, it is necessary to have proper lag time and enough stimulation.

Lag time is determined by the number of steps in the milking routine, size of the parlor and the number of cows an operator preps at one time. For example, a double-12 parlor at four turns per hour milking 672 cows in seven hours with a three-step milking procedure will have an average lag time of 1.5 minutes working sets of four cows at a time.

The same three-step milking procedure working sets of five cows will have an average lag time of two minutes, slowing down the parlor by 28 minutes.

Alternatively, a two-step milking procedure, working sets of four cows, will have an average lag time of one minute. This will speed up the parlor by 28 minutes. As a side note, in high-producing herds, lag times over 1.5 minutes are a much better choice to improve milk letdown and milk-out.

Scheduled milking equipment service

Depending on the farm, milking equipment works for 24 hours a day, 365 days of the year. In some cases, the milking equipment is the most neglected part of the dairy. Too often, I run into bottlenecks with the milking equipment when I’m trying to train parlor operators. Sitting down and planning with your milking equipment company a preventive maintenance schedule always pays off. Scheduled services can be categorized in four different areas:

- Wash system analysis to maintain bacteria counts down

- Replacement of rubber parts like gaskets and diaphragms, cleaning and maintaining takeoff cylinders and pulsator kits, changing air filters, greasing and maintaining hydraulic levels in gates

- A system analysis to determine how well variable-drive and vacuum levels are working during milking

- Upgrading components in the milking equipment (Some parlors that have been in operation for a long time may not be designed to carry the milk output of today’s dairy cows.)

Regardless of the size of your dairy, matching up parlor efficiency, labor and facilities are key elements for the profitability and success of your dairy.