When it came to the future of their dairy, owner Kenton Lindenbach says Robella Holsteins faced two options: upgrade their aging facilities or exit the industry. Wanting to expand on the work done throughout Robella Holsteins’ now 100-year history, Lindenbach; his wife, Alicia; and his parents, Reg and Julie Lindenbach, made the thoughtful decision to grow their herd, build a new robot barn and continue their hands-on management approach.

In February 2020, the farm – located in Balgonie, Saskatchewan – completed construction of their new barn, which features two milking robots, sand bedding, perimeter feeding, an automated feed pusher and an alley vacuum scraper. The Lindenbachs moved 66 milking cows to the new facility and increased their herd size; they now milk roughly 100 cows.

The motivation to construct a new barn arose from the manual labour demands of their former tiestall barn. “It would take 30-plus man hours per day just to really make it work the way we wanted it to,” Lindenbach says. With difficulties finding reliable labour and a young family, Lindenbach says it was not sustainable for the operation to stay on its former trajectory.

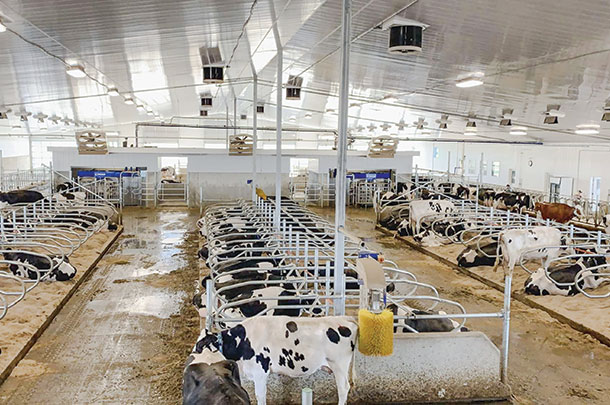

Since February 2020, Robella Holsteins have been operating their new barn equipped with two milking robots, sand bedding, perimeter feeding, an automated feed pusher and an alley vacuum scraper. Photo provided by Kenton Lindenbach.

Since February 2020, Robella Holsteins have been operating their new barn equipped with two milking robots, sand bedding, perimeter feeding, an automated feed pusher and an alley vacuum scraper. Photo provided by Kenton Lindenbach.

While Lindenbach notes there is still a labour element involved with the new barn, it now allows for greater flexibility in their management style and working hours. “We’ve got a really good peace of mind that those cows are being milked very consistently every single time they come versus if it’s a traditional tiestall, where you’d always have variability of who’s there and who’s doing the milking,” he says.

The former tiestall barn has since been retrofitted with six box stalls to house weaned calves from about 3 to 9 months old. Lindenbach says although the calves have only been housed in there since January, it is working well. “It’s nice to keep those calves out of the elements and the harsh prairie climate we often endure,” he says.

Before building a new barn, Robella Holsteins milked 66 cows in a tiestall facility. The facility has since been retrofitted to house the farm’s weaned calves. Photo provided by Kenton Lindenbach.

Before building a new barn, Robella Holsteins milked 66 cows in a tiestall facility. The facility has since been retrofitted to house the farm’s weaned calves. Photo provided by Kenton Lindenbach.

Although their new robotic milking system has allowed them to reduce labour requirements around milking, Lindenbach says they continue to stay actively involved in the operation through other channels, including a strong focus on herd genetics.

“The kind of cow we’re trying to breed is essentially what we think a lot of producers are looking for, which is a problem-free cow with a tremendous mammary system and great feet and legs. We really feel that in the last 10 years, moderate stature is something that’s become important to all producers for longevity of the cow,” he says.

Along with showing cows, the genetic side of Robella Holsteins has been an important part of their business long before their new barn was constructed. Lindenbach says in their tiestall barn, the farm was making more money on genetic and replacement sales than from their milk cheque. “That’s completely turned upside down; now you’re lucky to recapture your value of what you put into a replacement,” he says.

Knowing they would be expanding, Lindenbach says the farm began to modify their breeding philosophy early to accommodate for the changes in facilities but also for changes in the market. “We knew we were going to be making an upgrade in our facilities for the last five or so years, so we’ve been ramping up and using a lot of sexed semen on our better cows to try and increase our heifer population and not have to buy any replacements. Now that we’ve kind of reached our replacement requirements and the market is quite saturated, we’re doing a lot of selective mating and breeding cows that are still profitable and still work in our facility,” he explains. This shift in strategy has also opened Robella Holsteins up to crossing some cows with beef genetics. The beef-crossed calves are then sold to local farms, something Lindenbach says has provided them with a good return on investment.

Lindenbach says his interest in genetics comes from his desire to breed the next great productive animal. “It is really rewarding to see the decisions that you make to hopefully improve one generation over the next, and it’s always fun to push those boundaries of what is top-level production and what the next generation can improve upon,” he says.

Kenton Lindenbach and his family made the decision to upgrade their facility to remain in the dairy industry and continue their farm’s 100-year legacy. Photo provided by Kenton Lindenbach.

Kenton Lindenbach and his family made the decision to upgrade their facility to remain in the dairy industry and continue their farm’s 100-year legacy. Photo provided by Kenton Lindenbach.

Besides changes to their breeding strategy, Robella Holsteins have seen other changes since switching to their new robot barn. Lindenbach says the farm now sees “minimal” mastitis cases, which he attributes to their switch to sand bedding. They have also moved from blanket dry cow therapy to selective dry cow therapy.

“With the data we collect now, I can see what a cow’s somatic cell count has been during her whole lactation or within the last month or the last milking. We can then dry her off and make that decision; does she need to be therapeutic dry cow treated or can she get away with being [treated with] a protection barrier for mastitis or environmental mastitis?” he notes. Overall, Lindenbach says the new barn technology coupled with their animal monitoring systems has allowed them to detect and treat any “red flags” earlier.

Although their experience with their new facilities has been largely positive, Lindenbach says it was a challenge preparing the cows for the move to the new barn. While touring other facilities to get ideas for their own barn, Lindenbach says other producers warned him of the stress the move would have on the herd’s hooves as they adjust to concrete floors. He says no amount of preparation could have eliminated the problems this created during the first few months of operation in their new facility.

The cows have since adjusted to the flooring change, and Lindenbach says they have been able to focus on meeting goals like bringing butterfat production up to 2 kilograms per cow per day and keeping their milk quality high.

“So far, we’re pleased with the results we’ve seen, and we’re really looking forward to seeing what the future holds for us and what goals we can achieve. I think [our goals] are very attainable, but we’ll see how quickly we can reach them,” Lindenbach says.