Because feed costs are a very significant contributor to total running costs, they are a focal point for producers looking to reduce costs without negatively impacting animal performance and farm profitability. As forage inoculants come along as “one-off” purchases, they often become one of the first items considered for removal to lower expenses. You really need to take the time to review the potential impact this decision would have on your major feed materials – the cornerstones of the ration – especially in times of uncertainty around silage inventories.

Planning for silage needs

It is essential to get an accurate projection of the quantity of silage you need for the year, to avoid extra feed purchases to make up for shortfalls. You need to assess the herd size and specific needs of different breeds and groups – youngstock, heifers, milk cows, etc. – based on the experience and projections for your operation. Each group has specific dietary requirements based on factors such as age, breed, size and production goals. Understand the needs of each group, and you can build your inventory plan to match.

Another key component of planning is trying our best to anticipate environmental factors, such as drought, extreme temperatures or excessive rainfall, based on the local weather history. All can significantly impact forage yield and, ultimately, silage availability. According to Joe Lauer of the University of Wisconsin, corn plants under drought stress through pollination and grain filling suffered 32% lower forage yield and produced 37% less milk per acre.

Also remember that environmental factors, among others, also play a role in field yield losses, which are another key concern related to silage inventory.

Measuring actual silage inventories

Accurate measurement of your silage inventory is vital to determine the current feed supply and estimate how long it will last. A few methods have proven effective for measurement. Remember that you will need to factor in an estimate of the losses due to refusals for any estimation of feed availability.

Weight, yield estimates

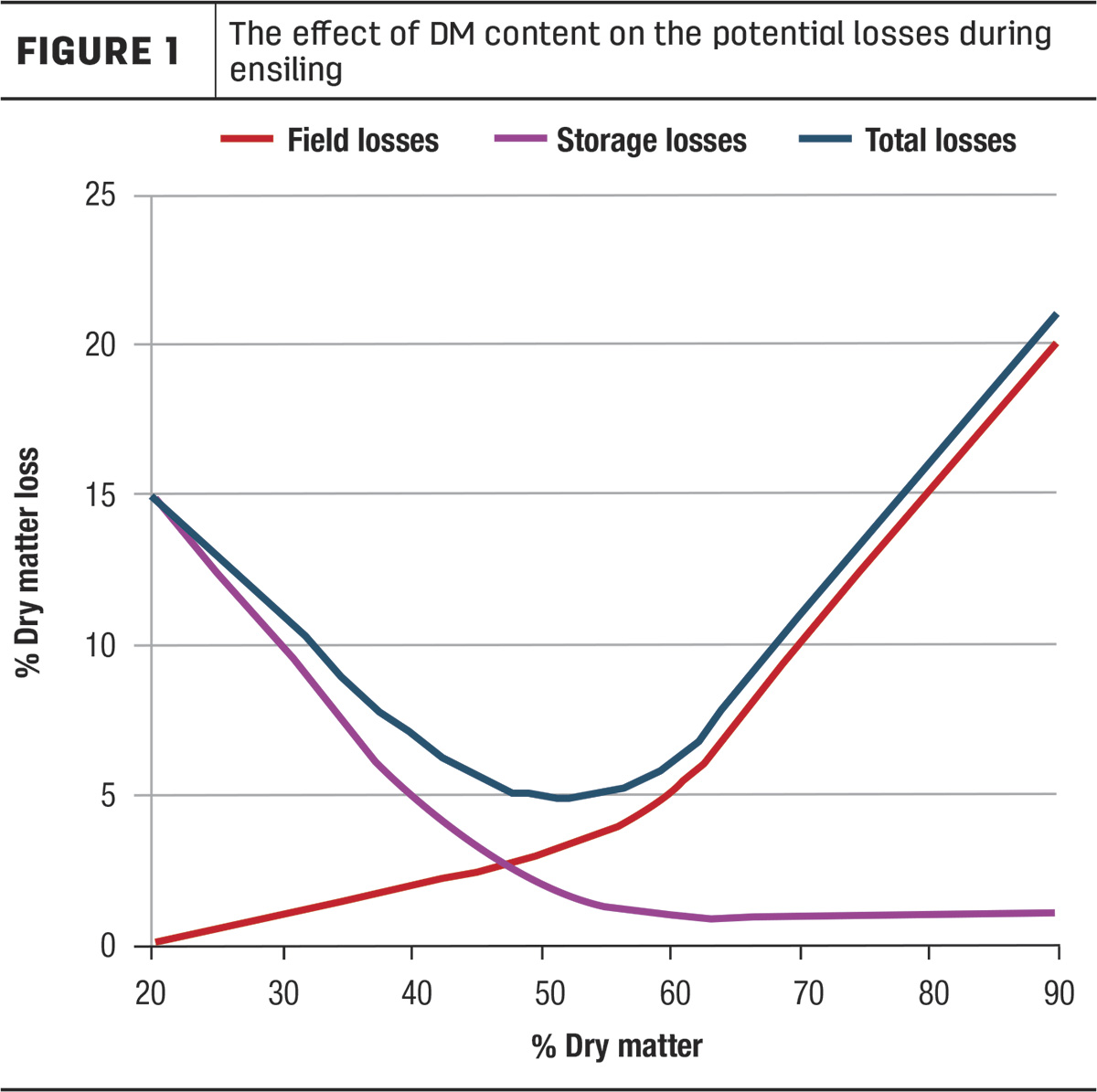

As the chopped forage crop is brought in from the fields, producers can weigh a truck before it’s packed. Once it’s packed and has been ensiled, they can keep track of how much they’re removing and calculate approximately how long they can pull from a pile until it’s gone. Using this approach, it is important to factor in an estimate of storage losses as accurately as possible.

University spreadsheets

The University of Wisconsin – Madison Division of Extension website offers a wide range of resources and calculators, including a spreadsheet that enables producers to calculate the volume and weight of the silage stored based on the type of storage structure, dry matter (DM) content, packing density, etc. This technique is limited by the accuracy of the various measurements and estimates (e.g., DM content and packing density) that will be measured for a small number of spots and used across the whole silage mass.

Drones

Drones equipped with advanced imaging technology capture aerial images and calculate the volume of stored silage. By only using a probe and drilling it into the face of the pile/bunker, producers can then have a rough estimate of the packing density. However, assuming that figure to apply to the entire silage mass to calculate the tonnage after a single drone flight would not give sufficient accuracy. Flights and packing density estimates should be performed at least quarterly for better precision of inventory measurements.

Most common causes of inventory shortages

While silage inventories can be impacted for a myriad of reasons, the most common include human error, weather, and unexpected disease and pests. However, good planning and execution of recommended management techniques will go a long way in protecting your inventories.

Human error

Human error typically means a lack of planning or precision in estimating inventories. When this happens, producers may need to get into other silages to balance out their inventory. When the other source of silage is the new-season crop, we can see issues related to early opening. When silos are opened early, there can be nutrient loss, increased spoilage, heating, mold development, and ultimately reduced feed intake and performance.

The general recommendation is that silages should not be fed before four weeks of storage. Moreover, corn silage, high-moisture corn, snaplage and earlage take longer to reach an optimal energy value, since starch digestibility increases with longer storage times; thus, three to four months of storage time is advisable. Opening before this means the silage nutrient profile will change over time since it is still “maturing” and this again needs to be factored in when designing rations and estimating inventories.

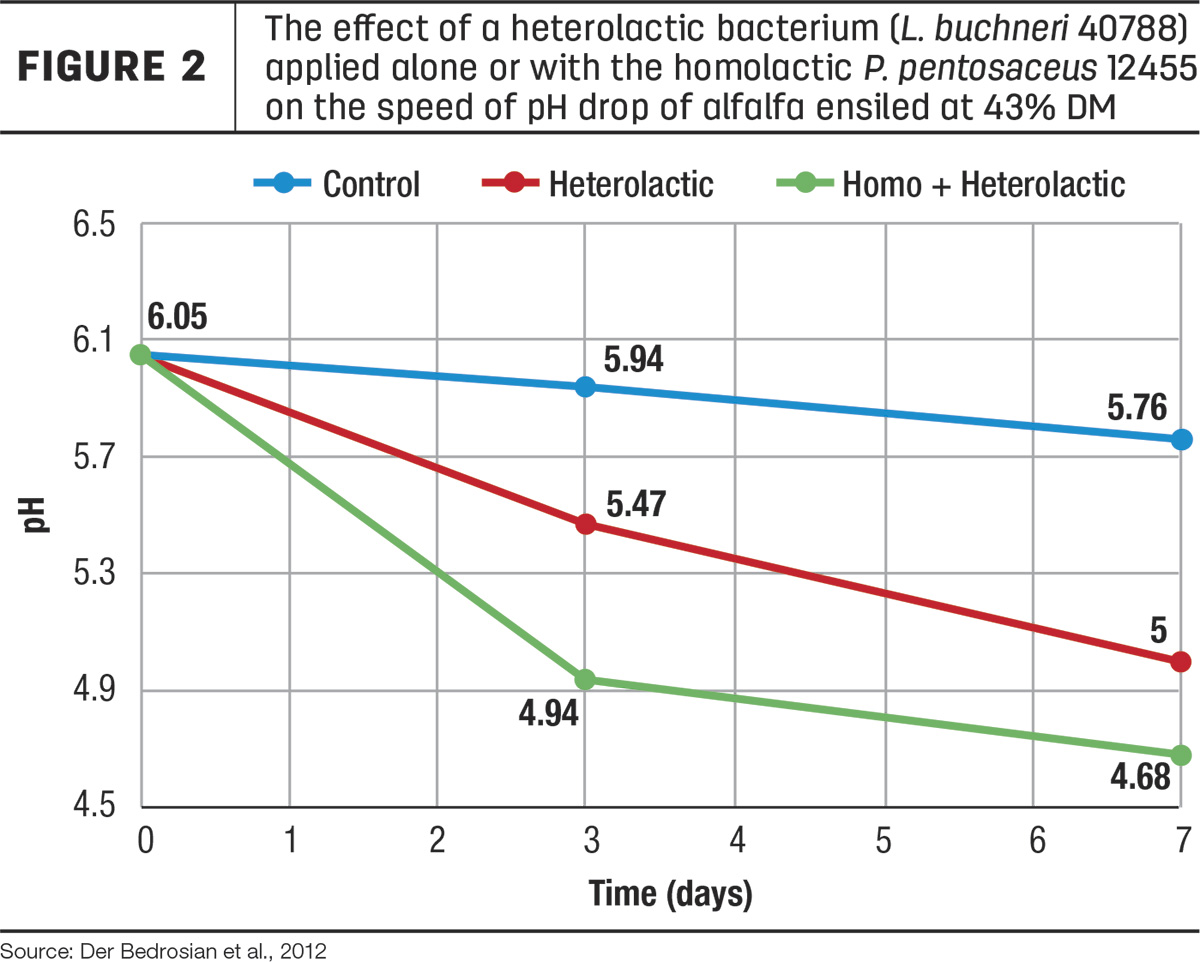

Crops ensiled for a very short period may not be completely fermented. In extreme cases of feeding out a forage crop that was just ensiled, monitoring the silage pH is an easy and quick way to keep track of the fermentation. A traditional or front-end inoculant is vital to aid the phase of active ensiling and speed up this process. Using a heterolactic lactic acid bacteria (LAB) – e.g., Lentilactobacillus buchneri – on its own is not as efficient (Figure 2).

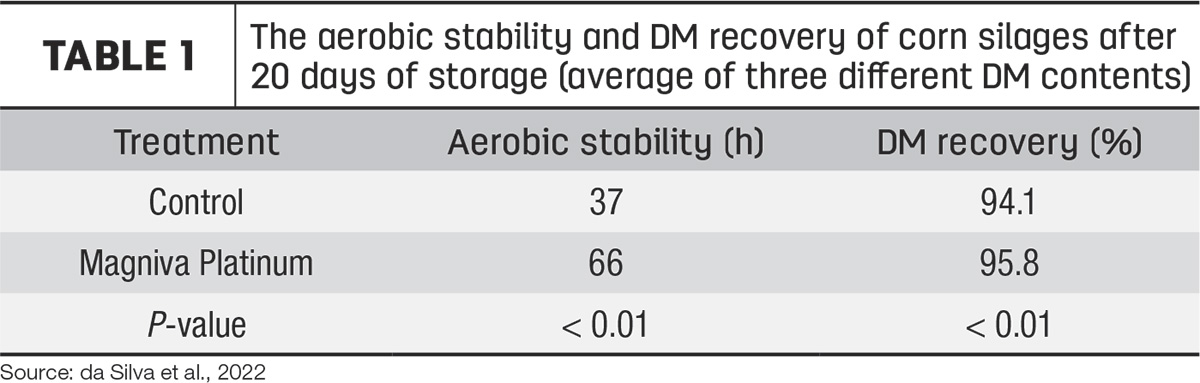

Another concern with silages stored for a short time is aerobic deterioration because of the high concentration of soluble sugars and insufficient levels of specific organic acids to preserve the silage during feedout. This is again where a proven silage inoculant can have a significant impact, and where the use of specific strains of heterolactic LAB can really make a difference. A combination of LAB strains proven to dominate the initial fermentation and improve aerobic stability in a shorter timeframe is recommended for more feedout flexibility. The newly patented Lentilactobacillus hilgardii CNCM I-4785, used in a combination formulation (MAGNIVA Platinum) has specifically been shown to speed up fermentation so producers can open their silage early while maintaining aerobic stability (Table 1).

Weather

As previously mentioned, the weather also plays a big role in inventory shortages. Drought and heat tend to be the biggest weather concerns producers face, but as unpredictability becomes commonplace, regions are adapting to the changes. In drought-ridden Arizona, we’re seeing more producers shifting away from corn silage and focusing on winter crops, which are grown during a period when irrigation water is less restricted.

Diseases and pests

However, even the most rigorous planning can’t account for some of the more unexpected concerns. Two other causes of unexpected shortages are disease and the presence of pests. For example, California had one of the wettest years on record, causing significant flooding, which buried crops in dirt and silt and led to several hygienic concerns in the crops (Figure 2). It’s impossible to predict every outcome, so it’s always a good idea to have a backup plan.

What to do when shortages happen

Some options are:

- Purchase more silage – The most efficient option might be to purchase silage from another producer to get through the season – if this is a possibility. Always be aware that changing the silage being fed will require some adaptation, and production levels may well change.

- Adjust the ration – Working with a nutritionist, producers can re-evaluate and reformulate the ration based on the available feed resources. This may include using less of certain ingredients and supplementing with others and may also mean refining production goals.

- Implement strategic feeding – This may include limit-feeding or extending the feeding period to stretch the available silage. In instances where feed is adjusted, specific feed additives may help maintain nutrition and performance.

- Alternative feedstuffs – Depending on the region, there may also be alternative silage crops that could be grown, byproduct feeds available, etc., that can help make up for the shortfall.

Proper and accurate planning for silage needs and estimation of inventories are essential for producers to ensure an adequate and consistent supply of their most cost-effective feed source for their animals throughout the year. There are several ways to measure inventory and strategies to address potential shortages, but it’s also important to understand the causes of short inventories and how to get the most quality silage to feed from the crops you grow.