The first year of milking cows in a rotary can be both a dynamic and humbling experience; the learning curve is different for every individual farm. We know that cows handle change better than people do, so finding ways to help reduce the stress on people during this transition period is important.

With a herd management system, we can measure post-rotary start-up progress using real-time milking session data. What you cannot measure, you cannot manage, and knowing where to set the bar for rotary performance during the first 12 months of milking is important for success.

What is parlor performance?

Before we dive into benchmarks, we need to understand what parlor performance is and why we need to track it. Parlor performance is an umbrella term that is both comprised and impacted by three subcategories: cows, employees and equipment. If one category is not performing to expectations, subsequently the other categories may be impacted. When all three categories are in harmony, we have the trifecta in place for optimal parlor performance. Tracking parlor performance allows for quicker improvement in milking efficiency, animal productivity, employee effectiveness and machine functionality.

Employee performance and consistency can impact both milking performance and cow throughput. By using reports that track milk flow in the first two minutes after unit attachment and milking incidents that occur over the duration of the milking, such as blocked units, liner slips and kickoffs, this provides a snapshot of what is occurring during each milking shift.

When monitoring cow throughput and operator interactions, these additional parameters can be used to evaluate parlor performance: length of milking sessions, number of rotations per milking session, number of cows milked per rotation and number of milking incidents. Regarding cow throughput, the number of cows milked per hour is an intricate parameter that is impacted by many variables. Some of these variables include rotary size, rotation speed, use of robotic teat sprayers, size of the milking herd, use of advanced milking automation technologies, average production of the herd and average milking duration.

Setting goals for your rotary parlor

In the year following rotary start-up, producers can expect their goals to change as they relate to parlor performance. Where a farm is in its transition and how aggressive it wants to be with its management dictates what their expectations should be for cow and rotary performance. Given the drastic difference in operational focus combined with new experiences for cows and employees, it makes the most sense to set different performance goals for three, six and 12 months post-start-up.

In developing benchmarks, farms representing roughly 163,000 cows milked in the U.S. on rotaries ranging in size from 72 to 120 stalls were surveyed. Keep in mind these benchmarks are not gold standards for parlor performance but are average, attainable numbers to strive for in the first year of milking if equipment is functioning to standard and herd health is maintained.

Three months post-start-up

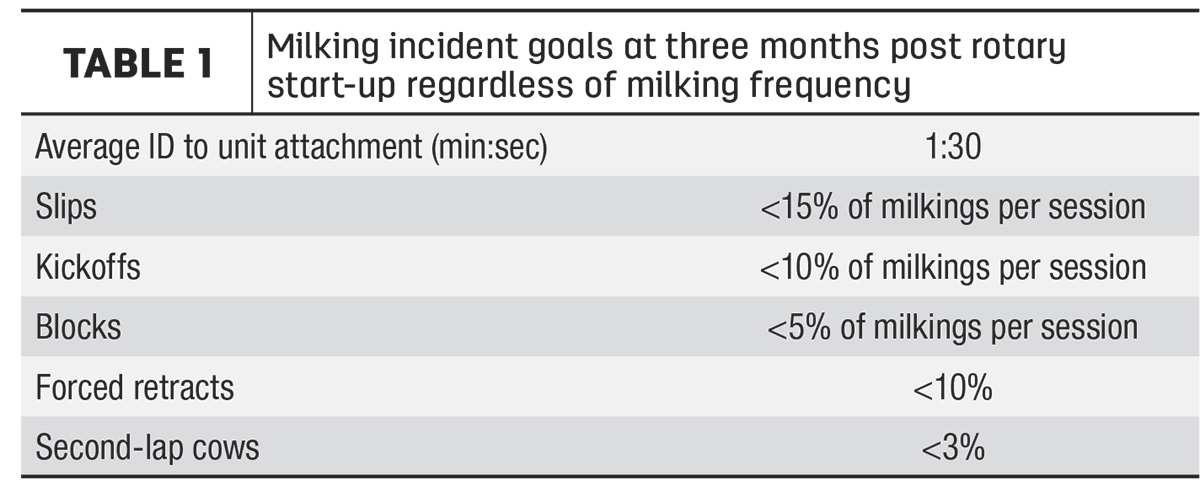

The primary focus of the operation is still training new cows and establishing shift routines among employees. Most cows should be loading and exiting smoothly except for fresh cows and new cows added to milking pens. While it is recommended to not stop the deck to train new cows, inevitably there may be a need to stop the rotary for cow safety purposes. The rotary should have a minimum of 85% of stalls occupied for all rotations. For herds milking twice a day, the average milking duration should not exceed five minutes and 30 seconds. For herds milking three times a day, the average milking duration should be about five minutes. Table 1 illustrates milking incident goals at three months post-start-up regardless of milking frequency.

If you are exceeding the recommended percentage of slips or kickoffs, liner fit or system vacuum levels may need further evaluation. It should be noted that the forced retract goal accounts for farms using a post-dipping robot, as there is normally an increased number of forced retracts to remove units before they reach the robot.

Six months post-start-up

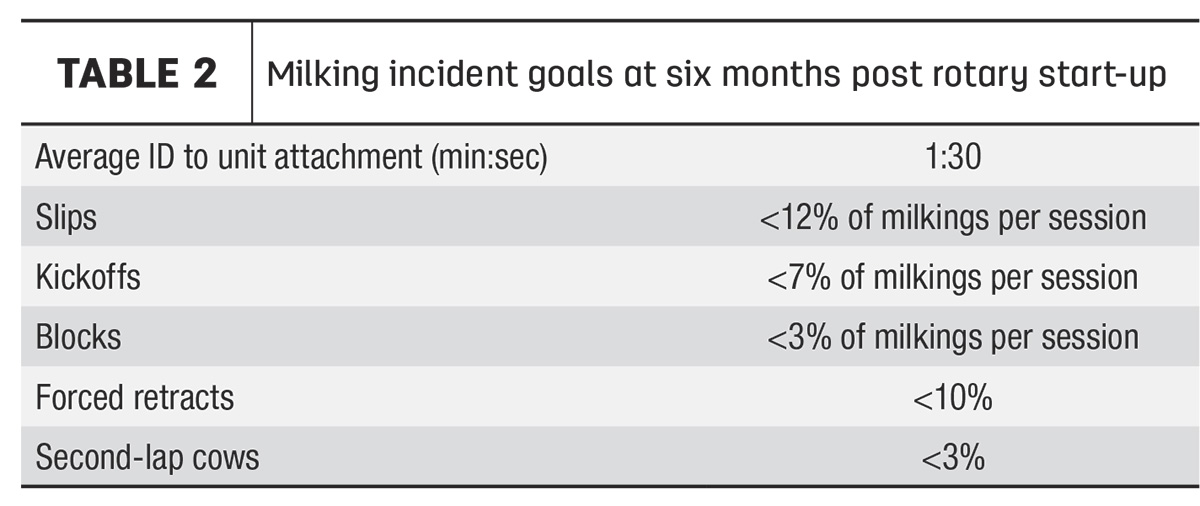

The primary focus has shifted from training cows to maintaining consistency in employee and cow performance. Cows should be loading smoothly – apart from new cows freshening into the herd or being brought over from other locations. The rotary should have 90% of its stalls occupied for each rotation. The rotary should be at full capacity and operating at maximum speed, which is dependent on the size of the platform, the number of cows being milked and the use of robotic teat sprayers. Milking durations for herds milked twice a day should be about five minutes and 15 seconds while herds milking three times should aim for four minutes and 45 seconds. For milking incident goals, see Table 2.

If there is bimodality in the first two minutes of milking, identify why this is happening and plan for small, incremental changes in employee-prep procedures to help improve the herd’s milk letdown.

12 months post-start-up

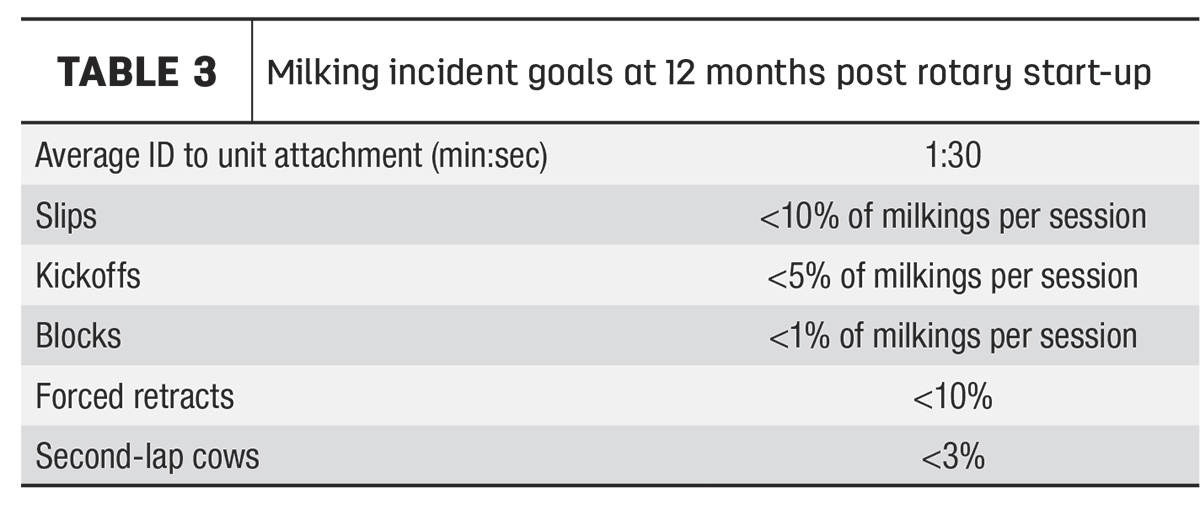

The end of the transition is in sight. Many farms are ready to fine-tune their performance by identifying cows that are not performing to herd expectations or examining employee procedural drift based on data collected over the course of the year. The rotary should have close to 95% of its stalls occupied during each rotation with minimal stops. For herds milking twice a day, the average milking duration should be five minutes or less. For herds milking three times, the average milking duration should be closer to four minutes and 30 seconds. Table 3 describes milking incident goals 12 months post-start-up.

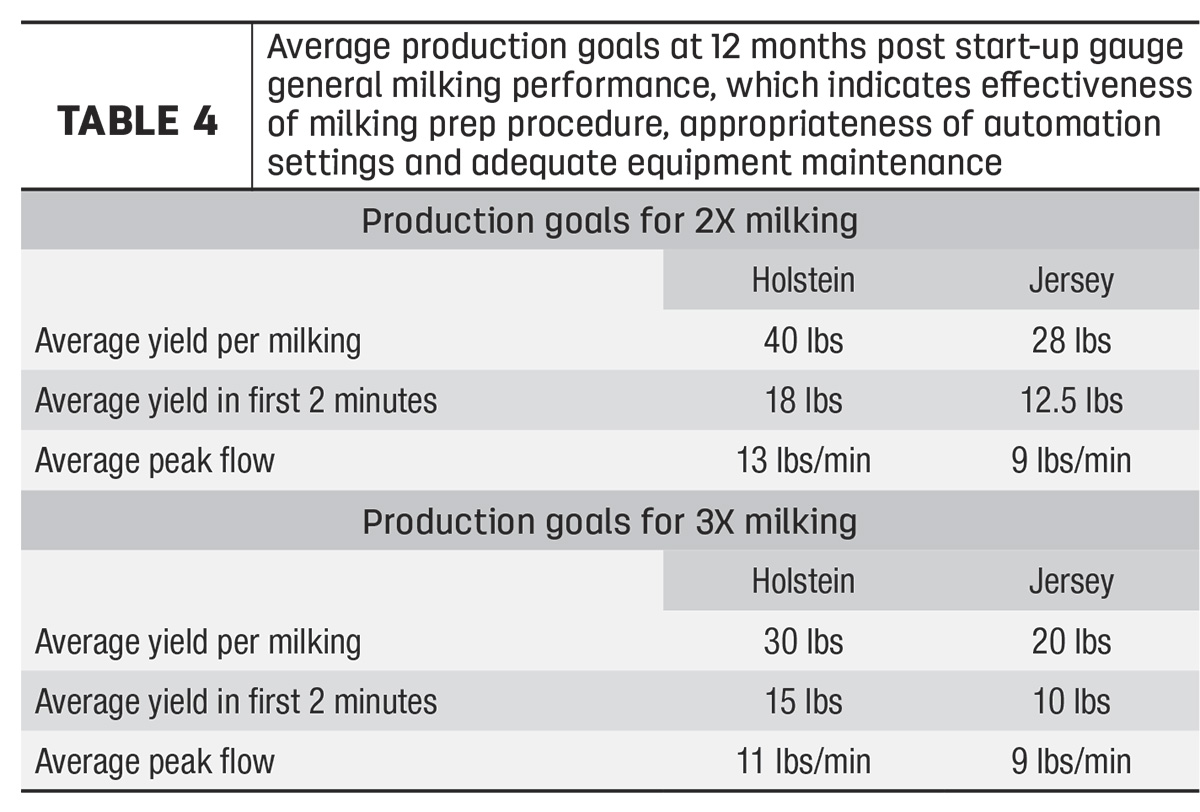

At the 12-month mark, farms should meet production goals listed in Table 4. These vary based on milking frequency and breed. These values do not account for milk components. The averages gauge general milking performance, which indicates the effectiveness of the milking prep procedure, appropriateness of automation settings and adequate equipment maintenance. Remember, employee development, animal genetics and routine maintenance all play a role in the maximum level of performance that is achievable for each individual farm.

Progress during your and your team’s first year milking with a new rotary can be a moving target, so keep your expectations realistic and stay committed to your short- and long-term goals.