Corn silage season is an exciting time in the dairy calendar year. It gives producers the opportunity to finish their forage season with a crop that, in many cases, sets the stage for the coming year's production.

A corn silage harvest with excellent starch availability, exceptional fibre digestibility and ideal fermentation profiles can mean milk production and components come easily while maximizing forage in the diet – thus, reducing feed costs. The opposite is also true: Poor-quality corn silage can result in struggles to meet production goals in addition to significant negative consequences for a dairy operation’s balance sheet.

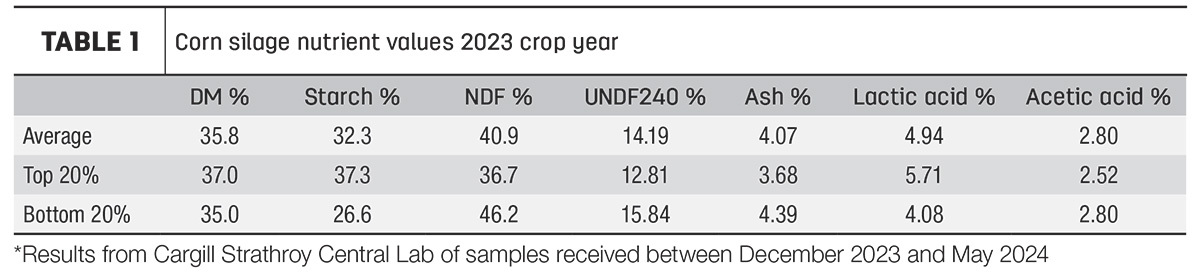

The economic impact of high-quality corn silage is often underestimated. To gain a better understanding of the impact of corn silage on a dairy operation’s bottom line, a dataset of just over 1,800 ensiled corn silage samples from the 2023 crop year was analyzed. Some of the key nutrients from the dataset are listed in Table 1. The average, along with the top 20% and bottom 20%, are categorized by net energy of lactation (NEL).

From a forage quality standpoint, the top 20% of samples are nearly 11 percentage points higher in starch than the bottom 20%. From a fibre (NDF) and fibre digestibility standpoint (UNDF240), there is a decrease in NDF of nearly 10 percentage points from the bottom 20% to the top 20% and an improvement in UNDF240 of nearly 3 percentage points from the bottom to the top 20%.

When comparing these silages from a nutrient standpoint, the top 20% result in silages significantly higher in starch, driving propionate production in the rumen. Propionate is a main volatile fatty acid (VFA) for milk production. Additionally, the lower NDF and UNDF240 in the top 20% result in more dry matter (DM) intake potential.

Not only did the top 20% of corn silages by NEL have higher nutrient quality, but their fermentation profiles were also better. The top 20% had higher levels of lactic acid and lower levels of acetic acid than the bottom 20%.

Lactic acid is the main fermentation acid in a well-fermented forage and its production during the ensiling process occurs quicker than acetic acid. A high level of acetic acid can indicate a slower fermentation, resulting in more DM loss of degradable carbohydrates in the silage.

Ash levels, which are indicative of soil contamination, were highest in the bottom 20%, which may contribute to poorer fermentation due to the presence of more soil-borne yeasts and clostridial organisms. These yeasts and organisms compromise fermentation and aerobic stability.

The difference quality corn silage can make on a ration

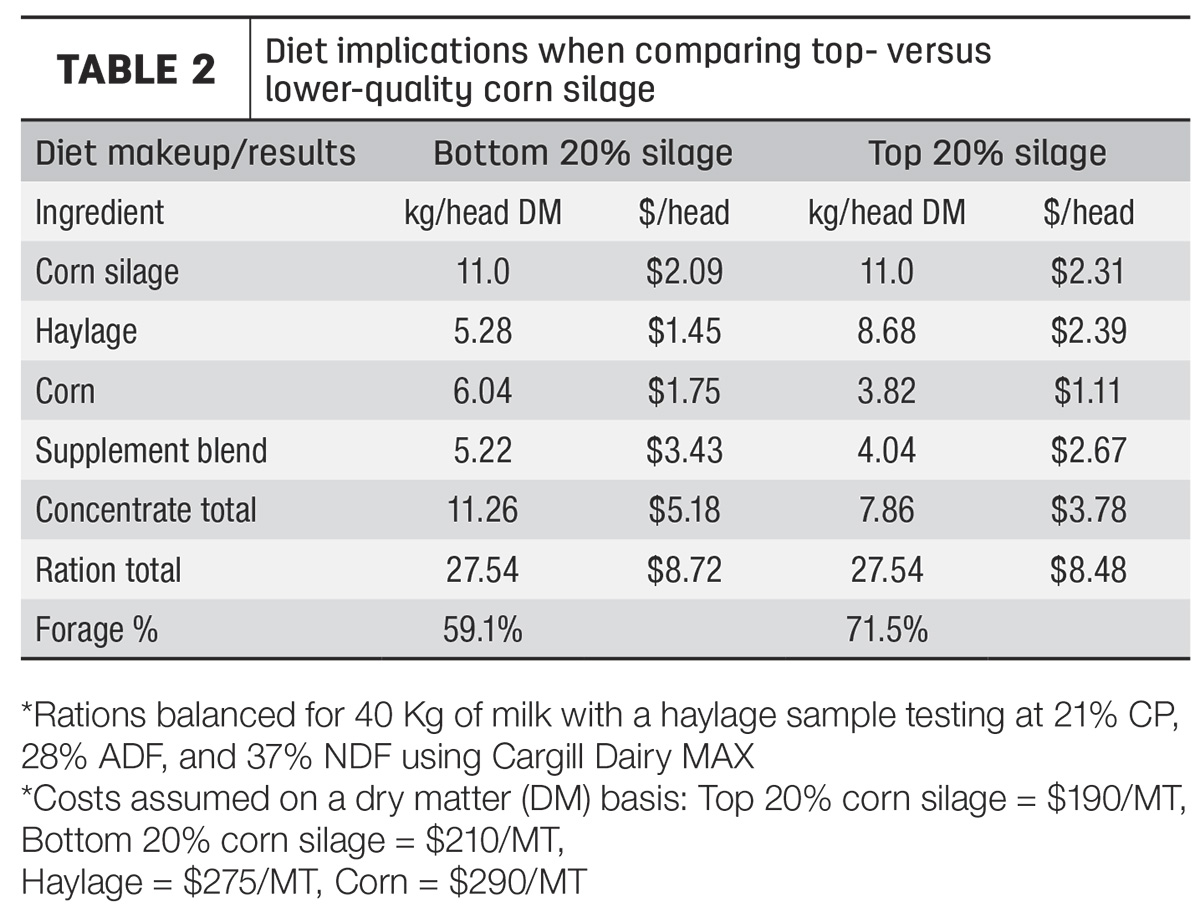

Rations were balanced using the top 20% versus the bottom 20% silage samples and fed at 11.0 kilograms DM in a typical scenario, with a high-quality haylage utilized for additional on-farm forage. Diet results are summarized in Table 2.

When looking at the diets, the most striking difference is the amount of total forage that can be utilized with high-quality corn silage. The top 20% corn silage samples result in over 12% more forage in the diet, or an additional 3.4 kilograms of DM coming from forage. To meet the energy requirement to support 40 kilograms of milk production, the diet with the bottom 20% silage needs an additional supplementation of 2.22 kilograms of grain corn to reach a similar rumen-available starch level. This additional corn takes up space in the diet, resulting in a lower feeding level of the on-farm haylage. The result is a diet requiring additional supplementation of protein and digestible fibre through concentrate sources.

From an economic standpoint, the difference in ration costs between the two scenarios is 24 cents per head per day but is even more accentuated when looking at the concentrate portion of the diets, where the difference is $1.40 per head per day.

On a 150-cow dairy, the difference in concentrate costs accounts for over $76,000 on an annual basis. Even if the dairy in this example was growing all their own corn for feed and only purchasing supplemental protein and minerals, the opportunity cost of selling the additional corn – were they feeding the top 20% silage – would amount to just over $35,000 a year.

At this point in the season, agronomic conditions during planting and growth, as well as weather, have for the most part had their impact on the quality of corn silage in the field when it comes to starch levels and fibre digestibility. However, the last few stages of making high-quality corn silage are yet to come: harvest, storage and ensiling. Getting these phases right will pay dividends in the coming year.

Set yourself up for a successful harvest

Harvesting high-quality corn silage starts with ensuring the crop is at the ideal DM. Testing whole-plant moisture leading up to chopping is an ideal way to ensure proper fermentation. Producers should aim for 32% to 38% DM in bunkers and bags or up to 40% DM in tower silos.

The second step is choosing an appropriate inoculant to promote ideal fermentation. Select a research-proven inoculant that fits the needs of the operation.

Inoculants with homofermentative bacteria strains limit DM loss of soluble carbohydrates by rapidly producing lactic acid, to then lower the pH and stabilize the silage. Inoculants with heterofermentative bacteria strains produce more acetic acid in conjunction with lactic acid, to improve aerobic stability and decrease silage heating around feedout.

The third step is determining cutting height and chop length. When determining cutting height, first consider how much silage inventory is needed. If all the silage corn grown is needed to fulfill the dairy’s requirements for the year, a typical cut height of 6 to 9 inches makes sense. However, if less corn silage is needed, high chopping up to 24 inches in height will increase fibre digestibility and concentrate the starch, therefore improving the quality of the silage. Chopping between 10 to 22 millimetres is common.

When determining chop length, consult a nutritionist and discuss factors such as total amount of silage in the diet, chop length of other forages going into the ration and production goals. Additionally, check kernel processing often and ensure less than two half or whole kernels are found in a litre of silage.

The final step to make high-quality silage is packing and covering. In a bunker silo or pile, use the rule of 400 kilograms for every tonne of silage coming in per hour, to determine how much packing weight is needed. As an example, if there is 100 metric tonnes per hour coming off the field, then 40 metric tonnes of tractor weight will be needed on the pile for adequate packing. Packing should be done in a progressive wedge pattern with layers no more than 6 inches deep to ensure adequate density.

Lastly, covering with an oxygen barrier and additional plastic, sealing the feed beneath with split tires (touching each other) and placing sandbags around the edges will minimize spoilage until the silage is ready to be opened post-fermentation.

Focusing on putting up high-quality corn silage can set the stage for milk and component production for the coming year. Attention to detail around all aspects of harvest from DM to inoculant usage, to chopping and processing, and packing can better preserve a high-quality corn silage crop. Ensuring corn silage is as high-quality as possible can have huge economic impacts including positive outcomes for dairy profitability.