Are you getting your milk quality bonuses frequently? How much money are you leaving on the table every month? How are you using your cow records to help you with your milk quality? With the current milk prices, you need that extra income more than ever. I will discuss some common cow record issues that will help improve your herd health and the quality of the milk you harvest. With good information and a hospital SOP, you could reduce your treatment costs and have healthier cows that will produce more and better quality milk to increase your dairy’s profitability.

Last spring, I met with a concerned Idaho dairyman to look into his high somatic cell count problem. He was completely frustrated with the situation and after trying different ideas to fight somatic cell count and bacteria counts, didn’t know what else to do to improve the quality of the milk he was producing.

After a long meeting in his office, we decided to tour his farm. We looked at his cows, talked to the milkers and inspected the milking machine. I proposed a hospital management and sanitation assessment as part of the mastitis diagnosis workup.

I got to the farm the following morning at 4:30 a.m. when Juan, the herdsman, was getting the medicine ready to treat the hospital pen. He had an old, small note pad in his hand the size of a small calculator. He opened this manure-stained notebook and started to read through it.

“These are all the treatments. I move all the information into the computer once a week,” he said.

I was shocked and amazed at the same time. How could this 2,500-cow dairy farm still have such an unreliable system to keep track of all the treated cows? What would happen with the records if Juan quits, gets sick or his notebook is lost?

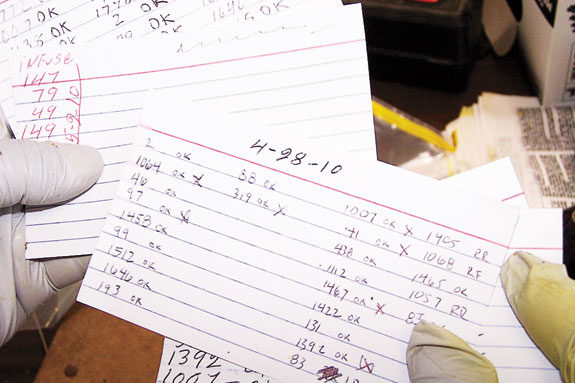

There are a wide variety of record-keeping methods being used today to help keep track of cow treatments. They range from simple paper-cardboard cow cards ( top right ) to more sophisticated electronic ones ( right ) built into most management software programs. As dairy operations grow bigger, newer technology is needed to be able to do the job efficiently and in a timely manner.

The technology is available, but how can we actually use it and benefit from it? If the valuable information we collect is never analyzed, then we’ve lost a long battle and also lots of time.

The information should be useful and readily accessible to help make a decision in a timely manner. If the wrong decision is made, we run into problems detrimental to the cows’ health and obviously to the overall profitability of the operation.

One common problem is cows that spend extremely long periods of time in the hospital for a mastitis case or just waiting for the intramammary antibiotic to clear their system. The losses due to drug costs, milk withdrawal and technician time are huge.

If the average cost of a regular mastitis case is roughly $200, you should multiply this number by the number of times a mistake is made in the diagnosis and treatment of a cow.

Interestingly, while some cows get extra “unneeded” treatments and spend extremely long periods of time in the hospital, many others are not treated long enough. Due to inadequate records, employee negligence, lack of proper training or guidance, cows don’t always complete their treatments. In some cases, cows may improve clinically after the first intramammary treatment, but that does not mean she is cured.

She might have moved from a clinical (visible) state of infection to a subclinical one (no evident change in milk characteristics with the naked eye). You may be tempted to stop the therapy at that time, and many people do.

Most of the time, one treatment will kill or inhibit some of the microorganisms present in the udder. If the cow’s immune system is not strong enough to clear the infection on its own, the bacteria will live in the udder and multiply again sooner or later.

By using only one tube, you might be selecting the resistant bacteria to that antibiotic because you don’t have enough concentration of drug in that quarter for the appropriate period of time. You are very likely creating a chronic mastitis cow. This subclinically infected quarter may not benefit from a later treatment with the same drug during that lactation.

Because of the selection of resistant bacteria in that gland and fibrosis (tissue reaction produced by the inflammation), the antibiotic may not diffuse properly to get where the bacteria resides. The likelihood that you will cure those cases after several treatments is obviously very low, so you should have a Plan B for these repeat chronic cows.

Don’t waste any more money!

What should you do?

Try to establish a system to record new cases of mastitis (incidence) and old cases (chronic or prevalent) that’s useful and simple for you and your employees to access and analyze. Review treatment progress and efficacy regularly with your personnel. This will allow you to make prompt and more accurate treatment decisions.

Identify the weaknesses in the system from your employees’ feedback. It’s a dynamic process. If your goal is to achieve better cure rates, my recommendation is to have a protocol and follow it all the way through every time with every cow. Better decisions are usually made when we have better information, so I recommend culturing cows before treatment.

I like to see a standard SOP or protocol posted in the parlor, both in English and Spanish, to help milkers understand the system you are using. New milkers will have to go through a training process to understand the system.

Review these procedures as often as needed until it’s natural for them. Review milk quality data that you receive from your processors and specify how their performance, milking routine and cleanliness is affecting key parameters like SCC, bacteria count, SPC, LPC, etc.

Work with your veterinarian and milk quality specialist to build a protocol based on milk cultures that specifically fits your situation. The protocol will help you reduce cow handling differences among operators.

If designed correctly, it can also reduce handling frequency and therefore contagious mastitis transmission rate. It will definitely increase cure rates and cut treatment costs while reducing the risk of converting curable cows into chronic ones.

The SOP should include treatment procedures, drugs and treatment dates with their respective milk and meat withholding time. This measure will help you reduce the problems you will encounter if drug residues are ever found in the tank or cow carcass.

FDA is actively looking for drug residue violators to ensure the safety of the animal products we consume. Our industry is a target of this intense scrutiny.

Make sure you have records of every animal being treated on the farm indicating pathology, drug used, route, dosage, day of last treatment as well as milk and meat withholding period. Avoid treating incurable cows to save time and money. Apply the “three strikes and you’re out” rule to diminish losses caused by chronic incurable mastitis.

Work towards better milk quality

• Keep records simple and accessible at all times.

• Build an SOP for hospital procedures and treatment protocols in English and Spanish based on culture results.

• Meet with your employees regularly – share milk quality data, explain their influence in milk quality parameters, set achievable goals and ask for their feedback. Listen to their concerns and suggestions.

• Evaluate treatment efficacy and drug use as needed.

The approach we took

I wrote an SOP for the hospital cows using culture results. I met with Juan and the milkers twice during hospital milking to explain the SOP and answer questions about the new treatment program.

We analyzed cow and farm records, including DHI tests. The owner culled some chronic cows with three teats and incurable mastitis.

We individually selected and dried up some chronic mastitic quarters and moved high somatic cell count (SCC) cows to a pen that is now milked last. Juan is updating the hospital information in the computer every day and using the protocol feature of DC305 to help him during hospital milking. He makes decisions based on current records information.

We reduced intramammary drug use more than 30 percent and cow handling time another 30 percent. As a result of these changes, we were able to reduce the SCC levels and get the bonus for the first time in over a year.

Conclusion

Many producers in the U.S. have deficient record-keeping practices. Few of them are really using these records wisely. We can benefit from correct analysis and interpretation.

Involve your herd veterinarian and milk quality specialist in the process. Take a closer look at your current record system to see what changes you should implement to improve its usefulness and make the information more accessible to its users.

Create an SOP and protocols for the hospital to avoid inconsistency in treatments. Training your employees to understand and follow changes in the new procedures is a key part to producing better quality milk.

Review records periodically and discuss treatment success and failure with your employees and your veterinarian. Milk quality bonuses can make up a very important part of your milk check. Don’t let them go. PD

Damian Lettieri

Veterinarian

Udder Health Systems

damian@udderhealth.com