Our industry has a reputation for producing safe and healthy dairy products for consumers around the world. From my perspective, this is due to the rigid testing of all meat and milk sent to market, coupled with a team effort between dairy producers, veterinarians and industry.

Yet, violations still happen, and this is not acceptable in the eyes of consumers. The tolerance level for any residue violation is absolutely zero, and since residues are measured in parts per million or parts per billion, this means one drop in an Olympic-sized swimming pool can cause an issue.

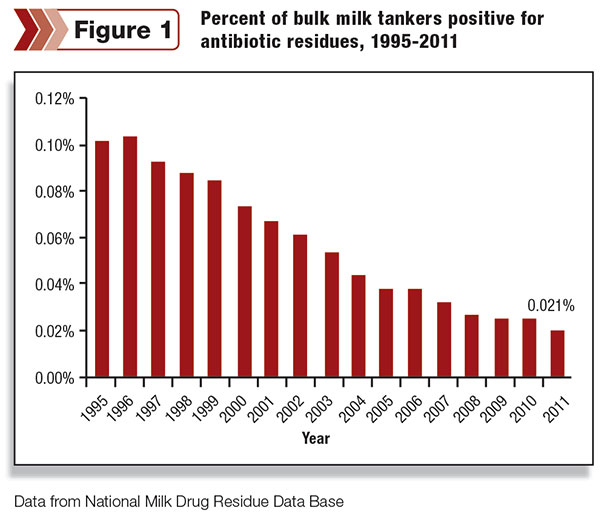

The good news is that our collaborative efforts are trending in the right direction. In fact, over the last decade, beta-lactam antibiotic residues in milk have declined by nearly 70 percent. From October 2010 to November 2011, industry and state agencies tested 3,182,972 milk samples and found that only 0.021 percent contained a volatile antibiotic residue.

What are these tests, exactly?

Letâs have a closer look at the testing process. Currently, state regulatory agencies test milk in accordance with the Grade A Pasteurized Milk Ordinance. This requires all bulk milk in tankers to be tested for the presence of beta-lactam antibiotics before being processed for human consumption. In addition, tanker loads are subject to random testing for further volatile residues.

If, during a random sample, a tanker is found to contain residue levels above the threshold, milk from farms that contributed to the positive tanker will be sampled and tested by a state agency. If not by a state agency, the Food and Drug Administration (FDA) will, within 48 hours, test the milk found to contain unacceptable residue levels.

Lasting repercussions

Tankers found positive for beta-lactam antibiotics are rejected for human consumption, with the violating producer potentially picking up the tab for the entire load. For an average-sized milk tanker holding 6,000 gallons, that could mean a $10,000 bill for your operation when milk is at $21 per hundredweight.

The impact of violation lasts beyond writing a check for contaminated milk. Producers found in violation of the residue level standards are put on an enforcement plan regulated by the farmâs veterinarian. Violators may also be subject to random testing, random searches of drug storage rooms and random reviews of written protocols and treatment records at any time.

It became evident to me early on in practice that prevention is the best medicine. Due to the serious implications volatile residues pose for both individual producers and the entire dairy industry, preventing antibiotic residues has become the primary focus.

Fortunately, dairy producers have several resources available to help manage proper antibiotic use on their operations. The greatest resource producers have at their disposal is their herd veterinarian. A valid veterinarian-client-patient relationship (VCPR) is at the foundation of risk management.

Tips to manage proper antibiotic use on-farm

- Establish a veterinarian-client-patient relationship (VCPR) to ensure proper diagnosis and treatment of disease.

- Keep records of antibiotic use, and identify all treated animals (e.g., with colored leg bands).

- Implement a preventive animal health program to reduce the incidence of disease.

- Maintain milk quality and implement an effective mastitis management program, including protocol development and review, to ensure the judicious use of antibiotics.

- Implement employee training and make them aware of proper animal drug use.

- Read the label. Utilize antibiotics approved for specific disease indications; follow all directions and withdrawal periods.

- Do not use drugs that are specifically prohibited for use in milking, dry or growing animals.

- Segregate and milk treated animals after, or in a separate facility from, all non-treated animals to ensure milk is not accidentally commingled.

- Use drug residue screening tests specific for the drug utilized before marketing milk or meat from treated animals.

- If in doubt about residue status, do not market milk or meat from treated animals.

These steps, as well as other valuable information about approved drugs and antibiotics testing, are available in the Milk and Dairy Beef Drug Residue Prevention Manual, which is available from the National Milk Producers Federation . PD

Brent Cousin

Professional Services Veterinarian

Boehringer Ingelheim Vetmedica, Inc.